11.6

Section 11

Reassembly

Throttle Lever

Dipper

Orientation

Piston

Index Mark

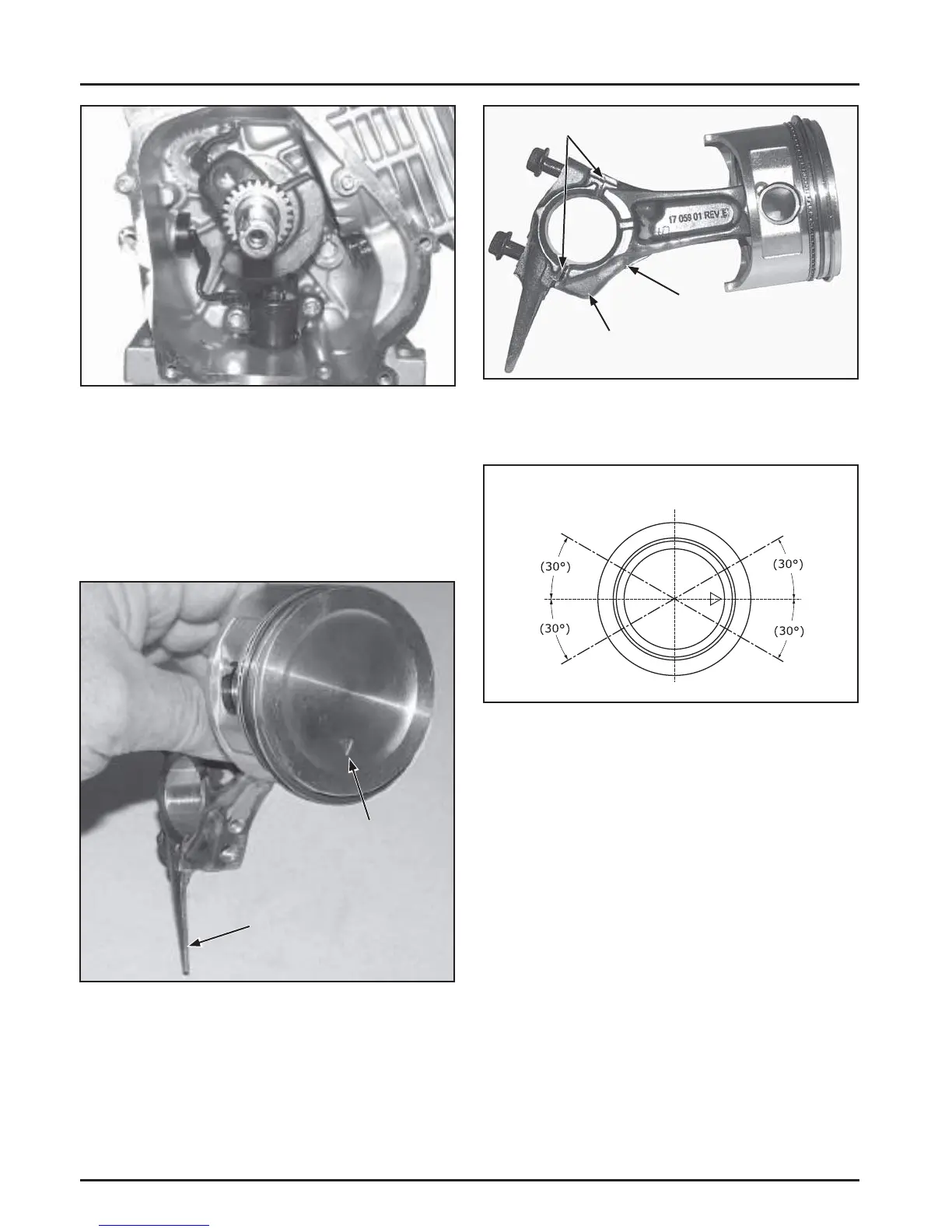

Figure 11-21. Piston/Connecting Rod Orientation.

b. The connecting rod off set is down and oil

hole is in the 4 o’clock position shown. Match

marks should align as shown with dipper

down. See Figure 11-22.

Figure 11-20. Installing Crankshaft.

Install Connecting Rod with Piston and

Rings

1. Make sure the following is correct before

installing.

a. The locating mark on the piston is down. See

Figure 11-21.

Connecting

Rod Offset

Match Marks

Oil Hole

Location

Figure 11-22. Connecting Rod Details.

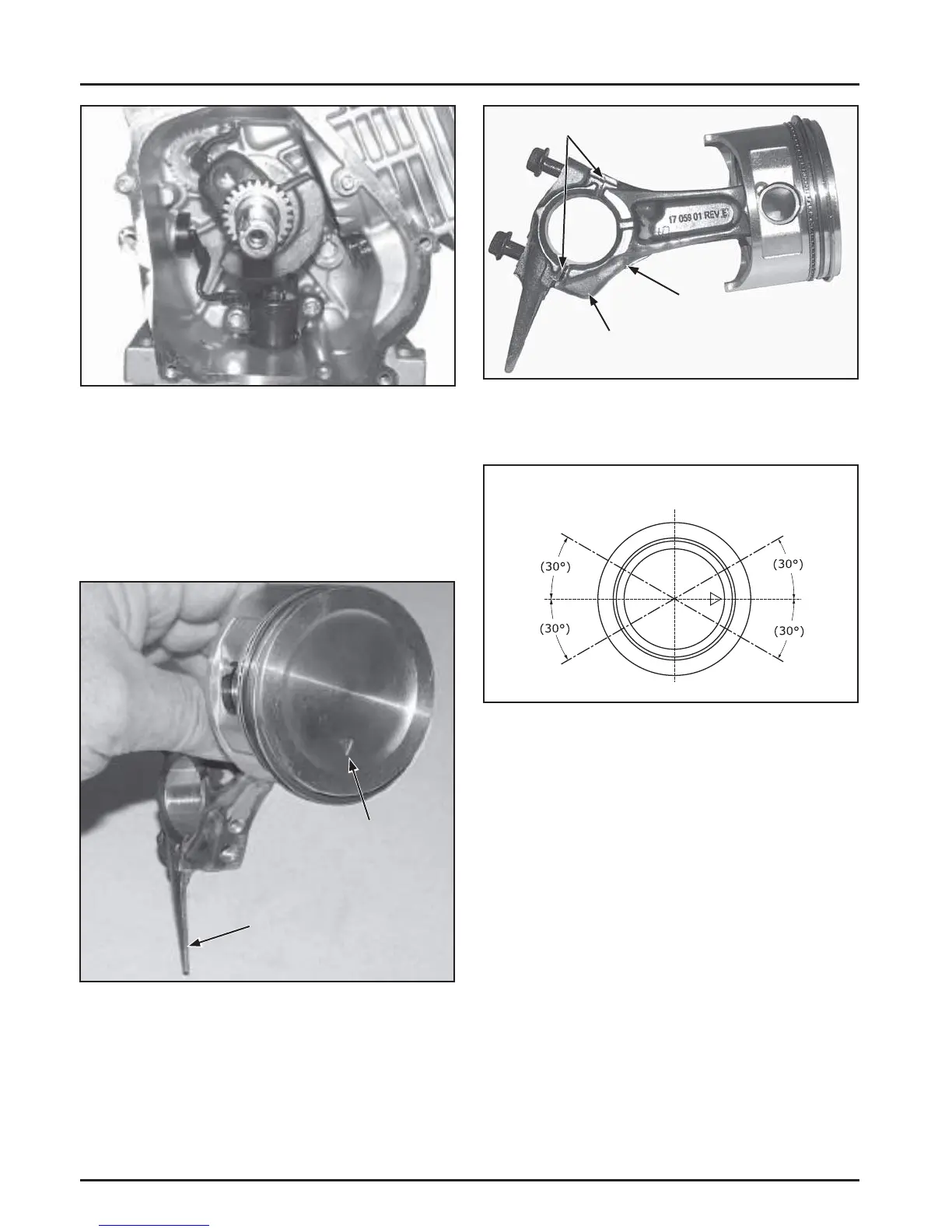

2. Stagger the piston rings in the grooves as shown

in Figure 11-23.

Oil Ring

Expander Gap

Top

Ring

Gap

2nd Ring

Gap

Bottom Oil

Rail Gap

Top Oil

Rail Gap

Figure 11-23. Piston Ring Orientation.

3. Lubricate cylinder bore, piston, piston pin, and

piston rings with engine oil. Compress the rings

using a piston ring compressor.

4. Lubricate the cranksha journal and connecting

rod bearing surfaces with engine oil.

5. Ensure ‘‘’’ stamping on piston is facing down

toward the base of the engine. Use a hammer

handle or rounded wood dowel and gently

tap the piston into the cylinder as shown in

Figure 11-24. Be careful that the oil ring rails do

not spring free between the bo om of the ring

compressor and the top of the cylinder.

Loading...

Loading...