POWERHEAD

90-883728 JULY 2001 Page 4A-47

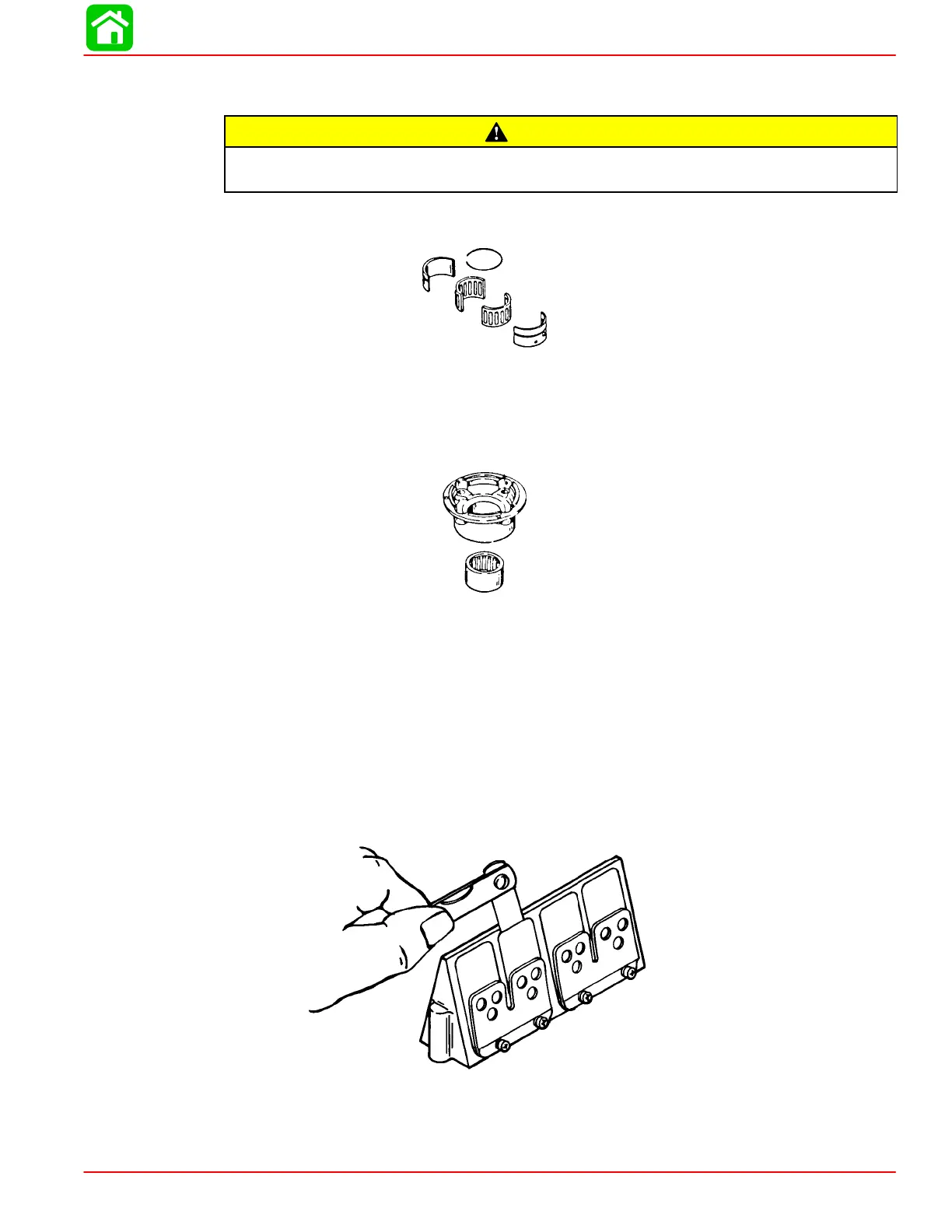

3. Thoroughly clean (with solvent) and dry crankshaft center main roller bearings. Lubri-

cate bearings with 2-Cycle Outboard Oil.

CAUTION

DO NOT intermix halves of upper and lower crankshaft center main roller bearings.

Replace bearings in pairs only.

4. Thoroughly inspect center main roller bearings. Replace bearings if they are rusted,

fractured, worn, galled or badly discolored.

Center main

Roller Bearing

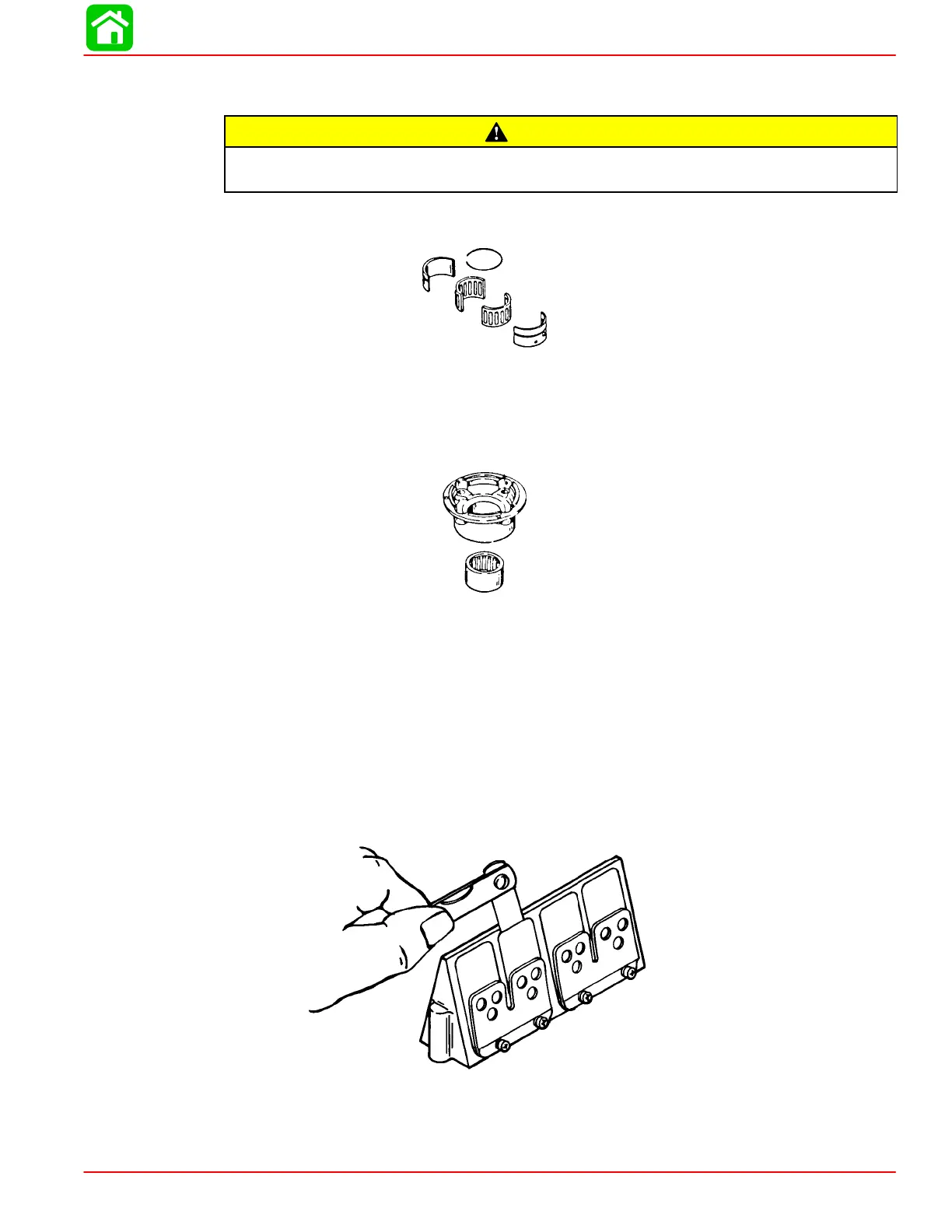

5. Clean (with solvent) and dry crankshaft roller bearing that is installed in upper end cap.

Lubricate bearing with light oil.

6. Thoroughly inspect upper end cap roller bearing. If roller bearing is rusted, fractured,

worn, galled, badly discolored or loose inside of end cap replace end cap and roller bear-

ing as an assembly.

Upper Roller

Bearing

Reed Block Assembly

IMPORTANT: Reed block assembly is not serviceable. If reeds are damaged replace

reed block assembly.

1. Thoroughly clean gasket surfaces of reed blocks and reed block housing. Check for

deep grooves, cracks and distortion that could cause leakage. Replace parts as neces-

sary.

2. Check for wear (indentations) on face of each reed block. Replace reed block assembly

if reeds have made indentations.

3. Check for chipped and broken reeds.

51851

Allowable reed opening is 0.020 in. (0.51 mm) or less. Replace reed block assembly if any

reed is standing open more than 0.020 in. (0.51 mm).

Loading...

Loading...