4 Basic Operation

4 - 16

E5@C-T Digital Temperature Controllers User’s Manual (H185)

3

Create

the pro-

gram.

• Set the program number to 0 (default). 4-39

• Set the parameter to 3. 4-40

• Set the parameter to the number of the segment to

edit.

4-40

• Set the following formats.

Segment 0: Ramp

Segment 1: Soak

Segment 2: Ramp

4-41

• Set the following SPs.

Segment 0: 100°C

Segment 1: None

Segment 2: 60°C

4-41

• Set the following slopes.

Segment 0: 4

Segment 1: None

Segment 2: 2

4-42

• Set the following times.

Segment 0: None

Segment 1: 40 minutes

Segment 2: None

4-42

• Set the parameter to PID set 1. (default). 4-43

• Set the alarm value to 30°C. 4-43

4

Trail

Opera-

tion

• Set the Run/Reset parameter to Run.

• Use the Process Value/Set Point 1/2 parameter in

the Operation Level to confirm that the PV has

reached 100°C.

6-14

5

Deter-

mine the

PID con-

stants.

• Execute 100% AT.

* The results are applied to PID set 1.

• Execute autotuning for the SP that is the most

important in control. For this program, autotuning

is executed for 100°C.

4-49

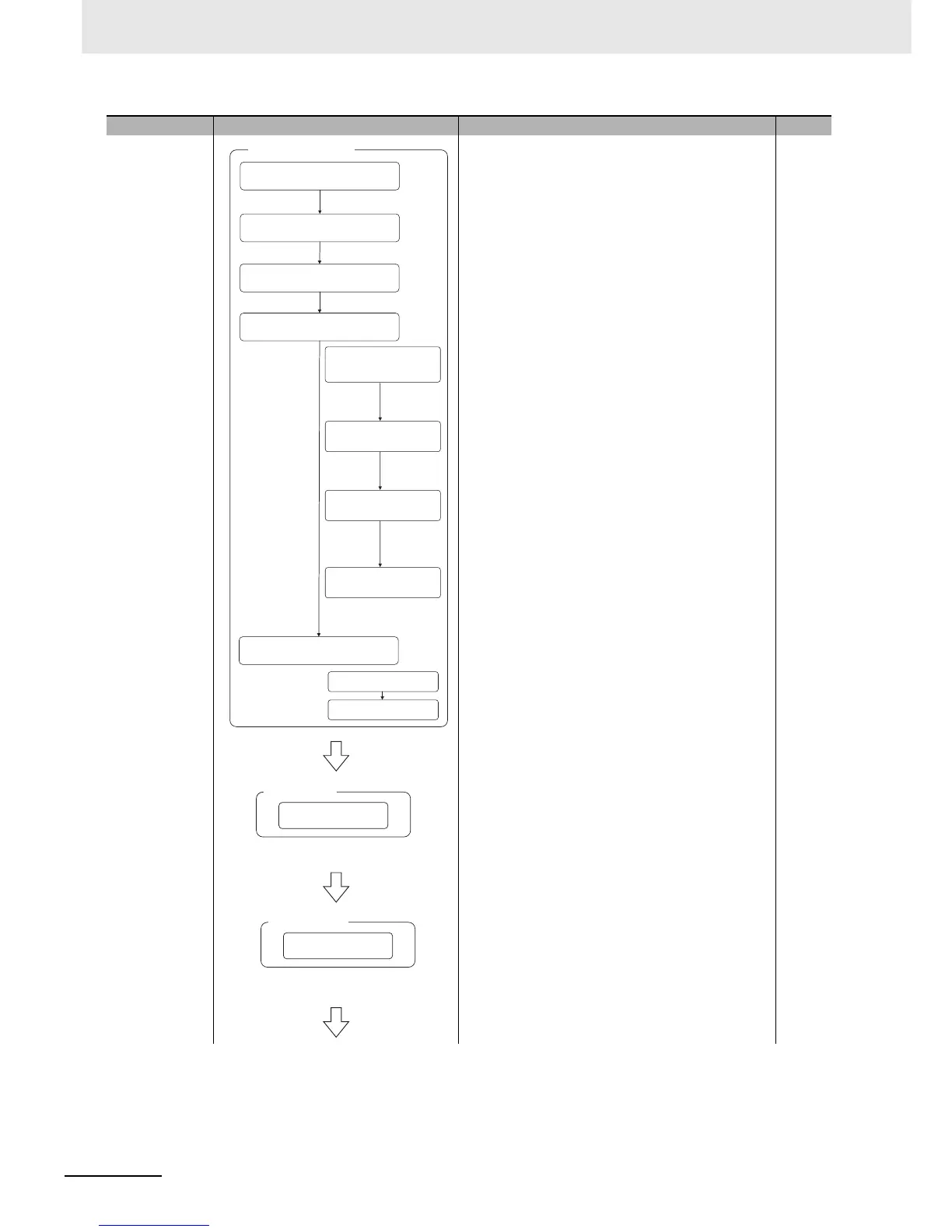

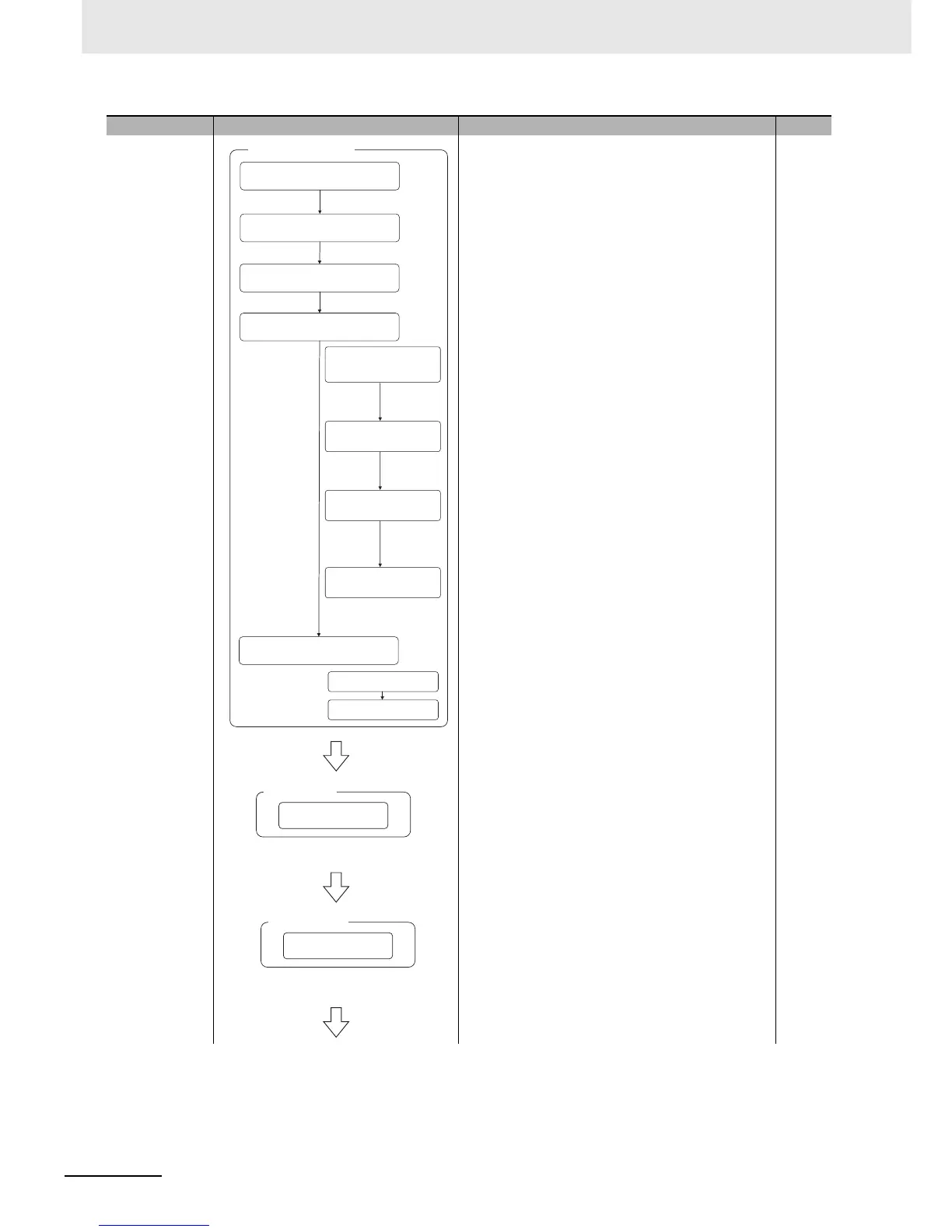

Item Operating flow Settings Page

Set the Program Number parameter.

Set the Number of Segments Used parameter.

Set the segments.

Program Setting Level

Set the segment formats

(for segments 0 to 2).

Set the segment SPs

(for segments 0 to 2).

Set the segment slopes

(for segments 0 to 2).

Set the segment times

(for segments 0 to 2).

Set the program.

Set the PID Set No. parameter.

Set the Alarm Value parameter.

Set the Segment Number parameter.

Start trial operation.

Operation Level

Execute autotuning.

Adjustment Level

Loading...

Loading...