9-13

1. Remove the brush block mounting screws and

lift out the brush block.

2. Remove the brushes and springs from the

holder and replace with new parts (see Figure

9-11 on Page 9-12).

3. Push each brush into the brush holder and in-

sert a stiff wire through the small hole in the

base of the holder. See Figure 9-4 on Page

9-6. The wire holds the brushes off the slip

rings during assembly.

NOTE: Inspect slip rings before installing brush

block. See

Slip Ring Service

following.

4. Install the brush block in endbell but do not

tighten the mounting screws.

5. Remove the wire holding the brushes off the

slip rings. Adjust the brush block so that the

brushes are centered on the slip rings, then

tighten the mounting screws.

6. Follow

Generator Assembly

procedures on

Page 9-7 to reinstall the fan hub and remain-

ing generator components.

Slip Ring Service

Follow

Generator Assembly

procedures on Page

9-7 through fan hub assembly removal. Inspect

the slip rings for grooves, pits, or other damage. A

Scotch Brite pad can be used to remove light wear

and for surface finishing. If the slip rings are rough,

pitted, or out of round by more than 0.002 inches,

recondition them in a lathe with a commutator

stone. Use the following procedure to service:

1. Follow

Generator Disassembly

on Page 9-2

to remove the generator endbell and rotor.

2. Place the rotor in the machine lathe and center.

Turn the rotor and use a commutator stone

(Onan tool #420–0259) against the rotating slip

rings to clean and true the slip rings. Turn the

rotor until all grooves or roughness are

smoothed out. Rub out must be less than

0.0001 inch, and surface finish must be less

than 32 micro inch.

WARNING

Contact with rotating machin-

ery can result in severe personal injury.

Keep hands and fingers clear while servic-

ing slip rings.

CAUTION

Careless handling of rotor can

damage the insulation on the windings.

Place rotor on protected surface when set-

ting down.

3. Clean the rotor and prepare for reinstallation.

Follow

Generator Assembly

procedures on

Page 9-7 to reinstall the rotor and remaining

generator components.

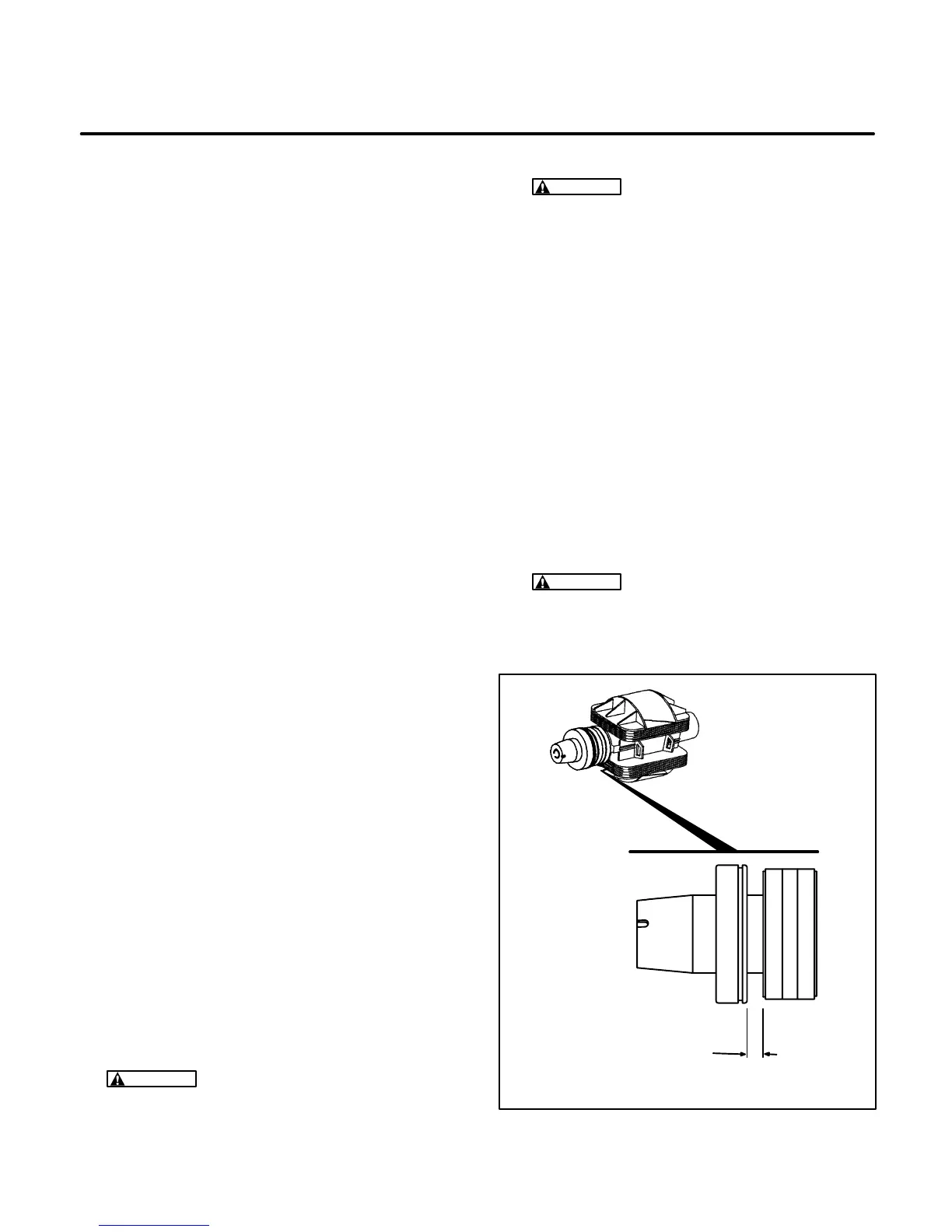

ROTOR BEARING REPLACEMENT

The rotor bearing is pressed onto the rotor shaft.

This bearing must be replaced very carefully to

avoid damaging the collector ring assembly and the

rotor shaft. Use the following procedures to replace

the rotor bearing.

1. Measure and record the distance between the

bearing and the collector ring assembly. See

Figure 9-12.

CAUTION

Heating the rotor bearing for re-

moval or installation can cause damage to

the bearing and the collector ring. Do not

heat rotor bearing.

G1216-1s

MEASURE SPACE BETWEEN

BEARING AND COLLECTOR

RING ASSEMBLY

FIGURE 9-12. ROTOR BEARING SPACING

Loading...

Loading...