10-11

Inspection:

When rebuilding the engine, thorough-

ly inspect the block for any condition that would

make it unfit for further use. This inspection must be

made after all parts have been removed and the

block has been thoroughly cleaned and dried.

1. Make a thorough check for cracks using any

standard method of crack detection. One

method of crack detection follows:

Minute cracks may be detected by coating the

suspected area with a mixture of 25 percent

kerosene and 75 percent light motor oil. Wipe

the part dry and immediately apply a coating of

zinc oxide (white lead) dissolved in wood alco-

hol. If cracks are present, the white coating will

become discolored at the defective area. Re-

place a cracked cylinder block.

2. Inspect all machined surfaces and threaded

holes. Carefully remove any nicks or burrs from

machined surfaces. Clean out tapped holes

and clean up any damaged threads.

3. Check the cylinder head mounting area for flat-

ness with a straight edge and a feeler gauge.

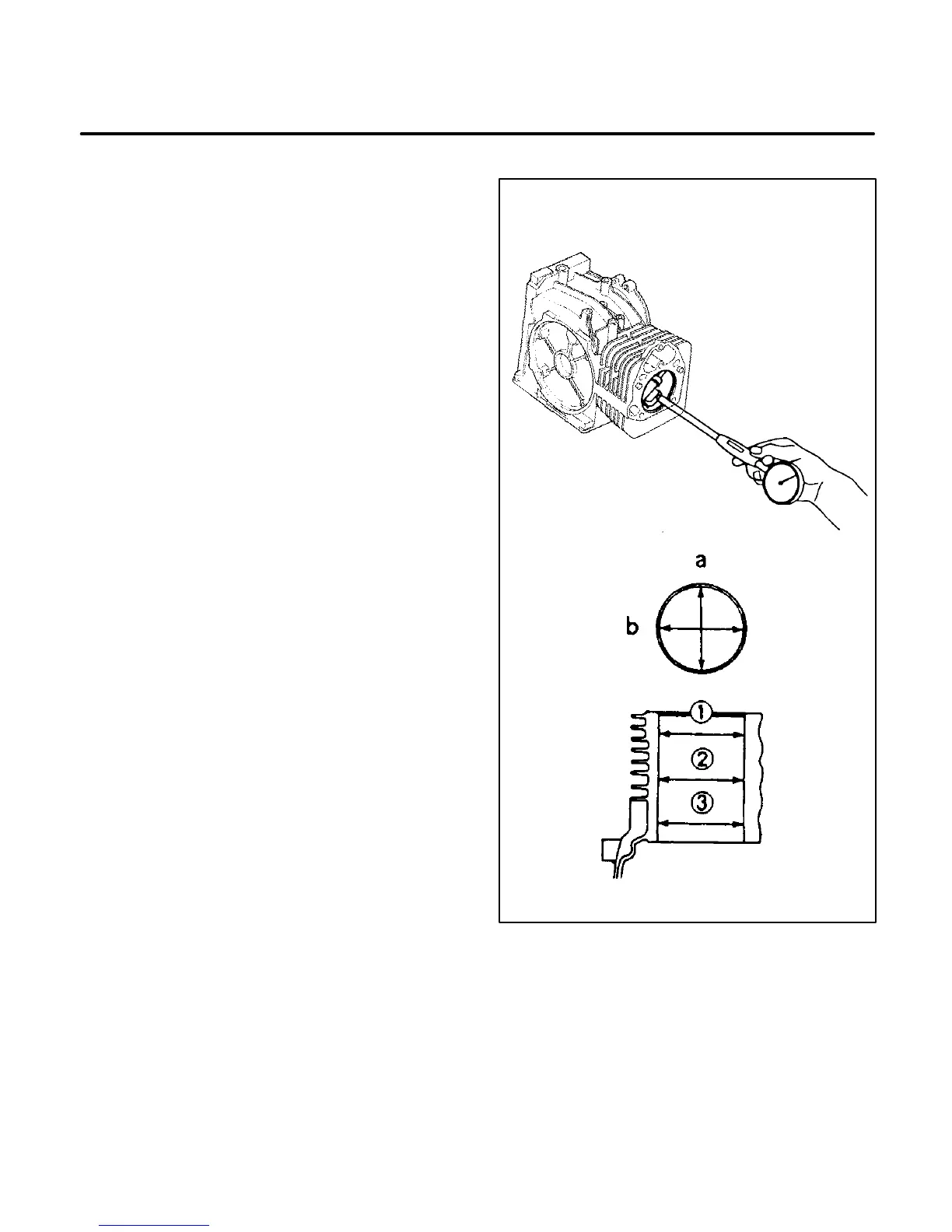

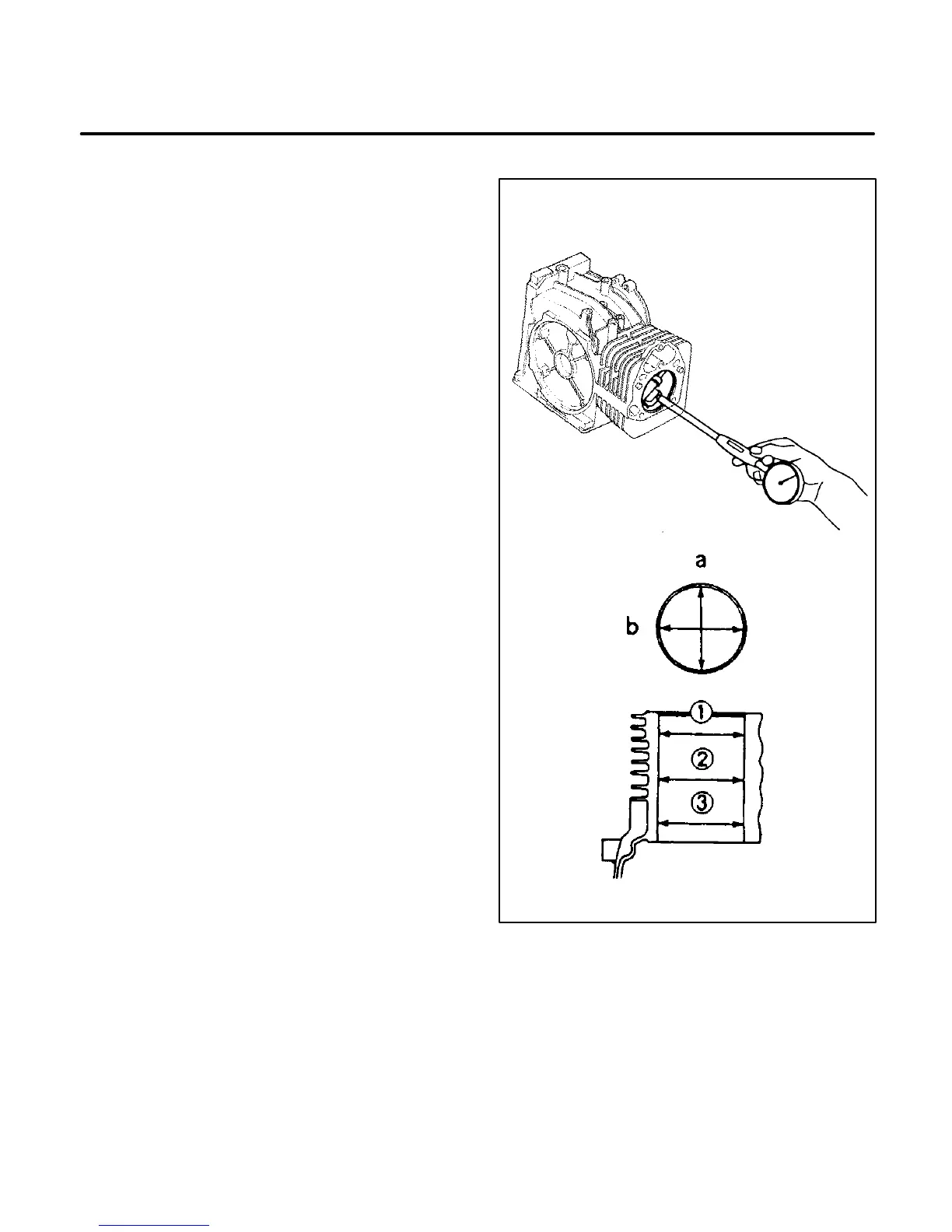

Cylinder Bore Inspection:

Inspect the cylinder

bore for scuffing, scratches, wear, and scoring. If

the cylinder bore is scuffed, scratched, scored, or

worn, the block must be bored to an oversize or re-

placed. When the appearance of the cylinder bore

is good and there are no scuff marks, check the cyl-

inder bore for wear or out-of-round as follows:

1. Measure the I.D. of the cylinder liner with a cyl-

inder gauge at six points as shown in Figure

10-20.

2. If the measurement exceeds the allowable lim-

it, the cylinder will need to be bored to an over-

size and then be honed.

FIGURE 10-20. MEASURING CYLINDER WEAR

Loading...

Loading...