10-7

Valve Clearance Adjustment

The valve clearance can be checked and adjusted.

Adjust the valve clearance only when the engine is

at ambient temperature.

1. Follow head cover removal instructions in the

Head Cover

section on Page 10-2. Inspect

the valve stems for proper alignment with the

rocker arms.

2. Advance the engine until both of the valves are

closed and there is no pressure on the valve lift-

ers (piston at top dead center).

3. Clearances are shown in Section

3.

Dimen-

sions and Clearances

. For each valve, the

gauge should just pass between the top of the

valve stem and the rocker arm. (See Figure

10-11.)

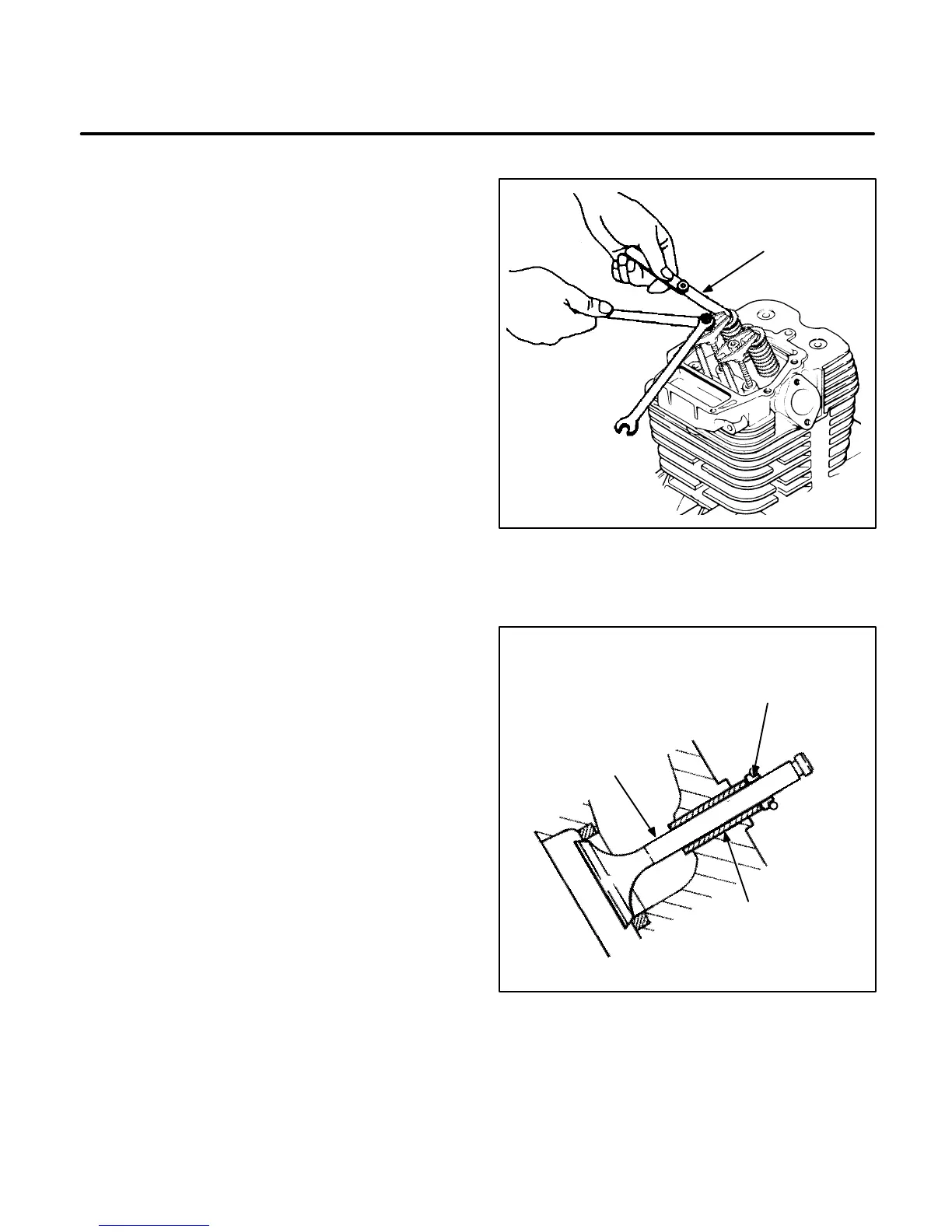

4. To correct the valve clearance, place a wrench

on the adjusting nut and a wrench on the outer

locking nut. Loosen the outer locking nut and

turn the adjusting nut as needed to obtain the

correct clearance. Tighten locking nut after ad-

justment is made.

5. Recheck the valve clearance after adjustment

has been made and also check the rocker arm

bolts to see that they have not loosened as a re-

sult of adjusting the valve lash.

6. Reinstall the head cover and torque the head

cover bolts to the specified torque.

Intake Valve Seal Replacement

A worn or cracked intake valve seal can cause high

oil consumption and spark plug fouling. Replace a

defective intake valve seal as follows:

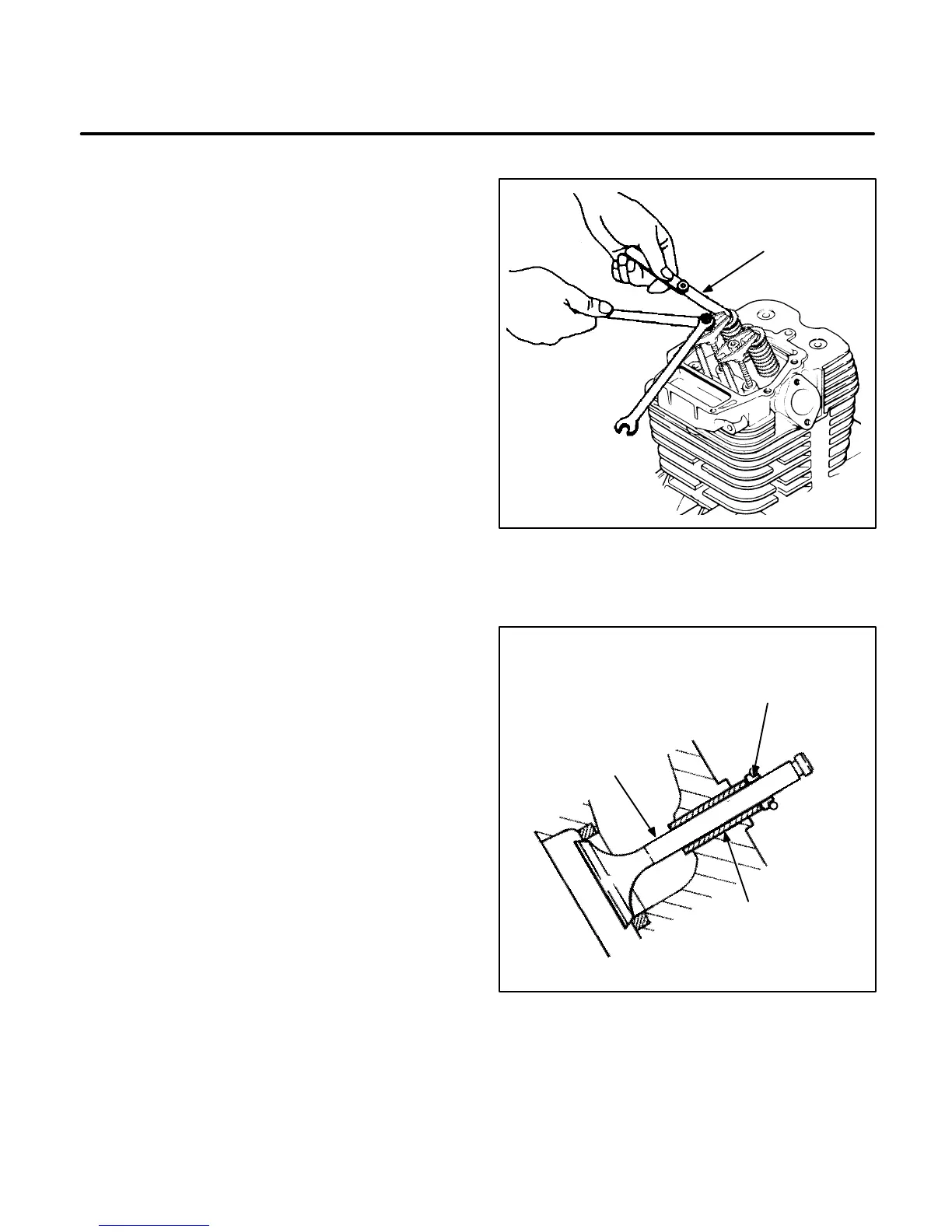

1. Pull the old valve seal out carefully to avoid

damaging the valve guide.

2. Coat the intake valve stem with engine oil and

insert it into the valve guide.

3. Press the valve seal into the valve guide by

hand until the shoulder of the seal rests against

the cylinder head (Figure 10-12).

FEELER

GAUGE

FIGURE 10-11. VALVE CLEARANCE ADJUSTMENT

VT1043-1s

VALVE

SEAL

INTAKE

VALVE

VALVE

GUIDE

FIGURE 10-12. VALVE SEAL INSTALLATION

Loading...

Loading...