8-29

Starter Re-assembly

Use this procedure to return the electric starter as-

sembly to service.

1. Wipe all of the dirt and oil from the starter com-

ponents with a clean cloth. Blow off dust with fil-

tered low-pressure compressed air.

CAUTION

Oil on the armature will damage

the starter. Do not immerse bearings in

cleaning fluid. Use a brush dipped in clean

engine oil to remove dirt from bearings.

Avoid getting oil on brushes or commuta-

tor.

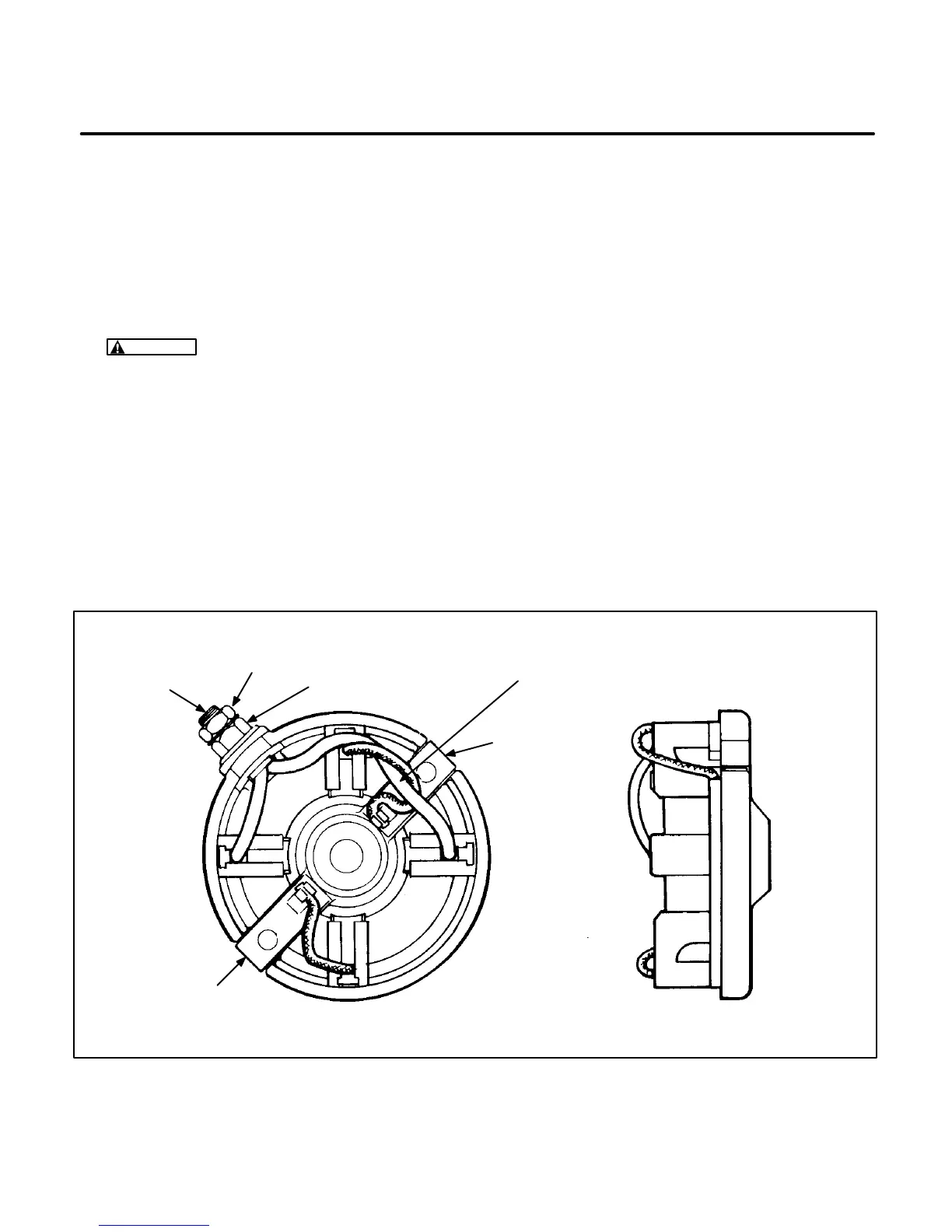

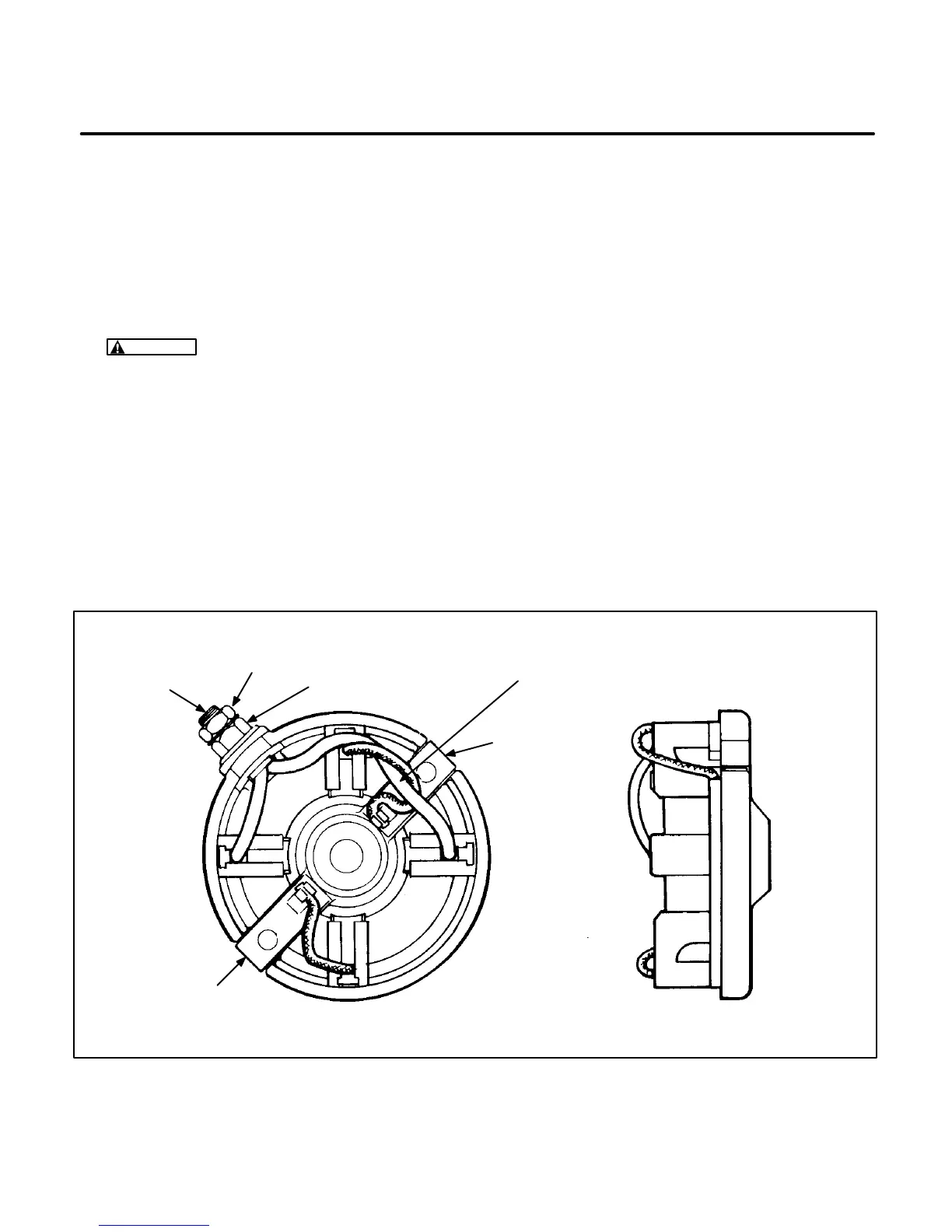

2. Push the negative brush terminals over the

through-bolt holes on the brush endcap (Figure

8-28).

3. Insert the positive brush stud into the hole, and

torque to 25-30 lb-in. (2.83 - 3.39 Nm).

4. Insert the brush springs into brush holders. In-

sert the brush tabs into the spring ends and

slide brushes into brush holders in endcap.

Make sure all brush wires are facing up.

5. Place a washer on the commutator end of the

shaft, then put the armature into the brush end-

cap. Push the four brushes toward the commu-

tator, make sure that the springs are correctly

positioned on the brushes.

NOTE: Replacement brushes are supplied

preassembled in the endcap. Remove the brush

retainers after installing armature.

6. Make sure that all brush wires are clear of the

commutator, and that uninsulated sections of

wires do not touch the inside of the housing, or

adjacent brush boxes.

7. Place the magnetic housing over the armature.

Hold down the armature and the end cap by

pressing a nut driver over the end of the shaft.

TORQUE TO 510 INLBS

(.571.13 N

•M)

TORQUE TO 2530 IN

LBS (2.833.39N

•M )

IMPORTANT! THIS INSULATED SHUNT MUST

BE ROUTED THROUGH UNINSULATED SHUNT

AS SHOWN TO PREVENT CONTACT WITH

COMMUTATOR IN FINAL ASSEMBLY.

NEGATIVE BRUSH

TERMINAL

POSITIVE

BRUSH

STUD

NEGATIVE BRUSH

TERMINAL

ES-1612-2s

FIGURE 8-28. BRUSH ENDCAP

Loading...

Loading...