10-20

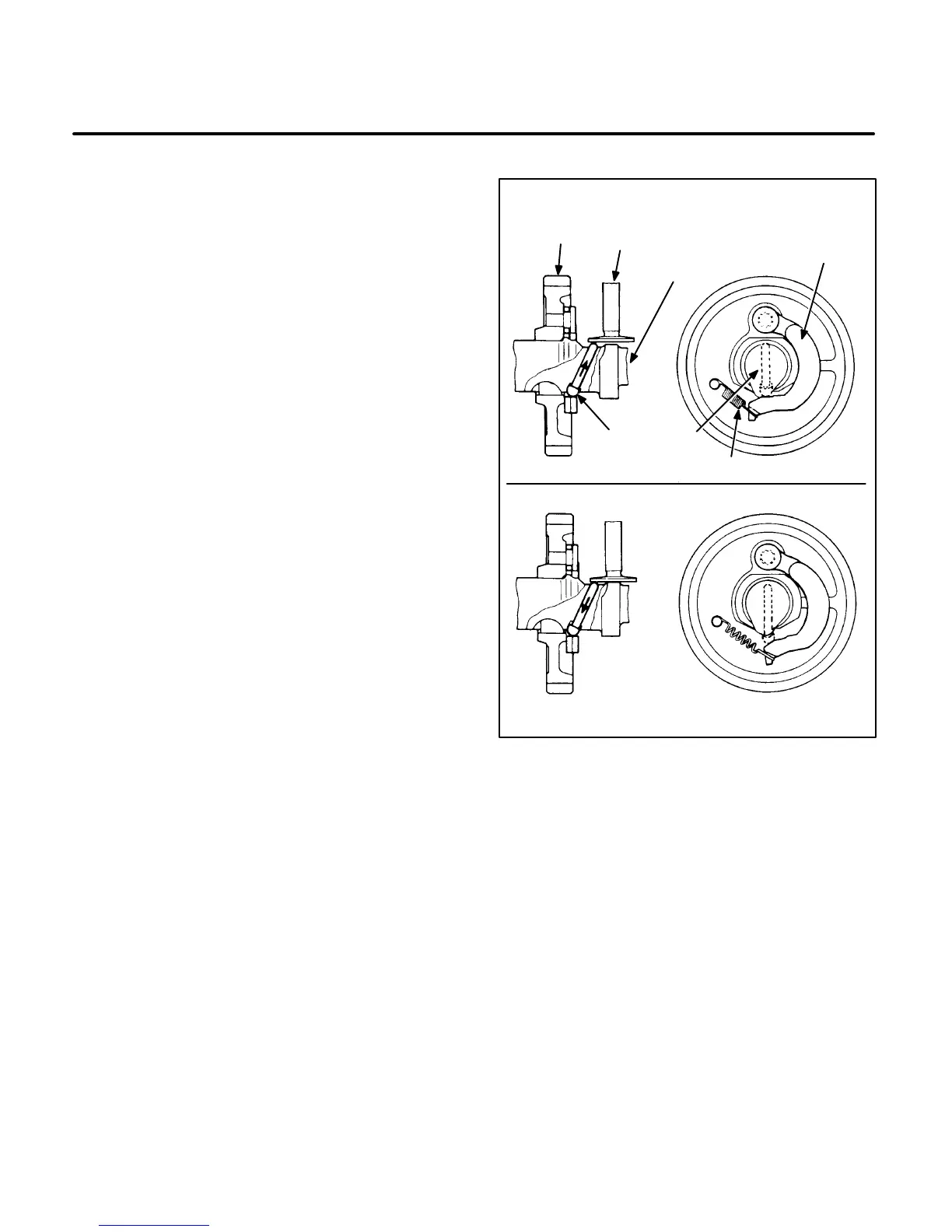

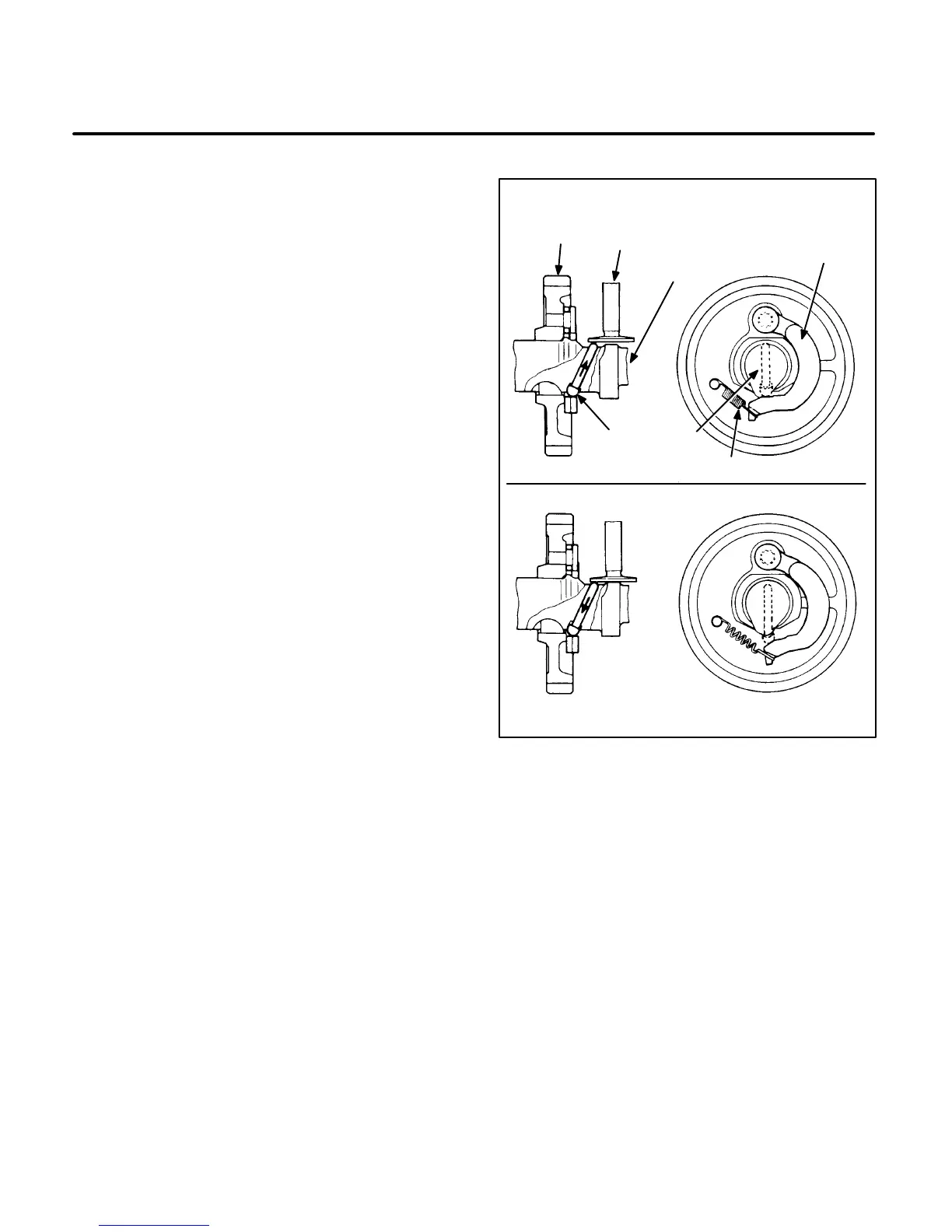

COMPRESSION RELEASE SYSTEM

(SPEC A-D ONLY)

This engine has a compression release system that

decreases the amount of effort required to start the

engine and reduces engine run-on when stopping

(Figure 10-38).

The system works as follows:

1. As the engine is started, a spring holds in the

flyweight which in turn pushes a decompres-

sion pin upward.

2. The decompression pin pushes up on the ex-

haust tappet and opens the exhaust valve mo-

mentarily to release compression and make

starting easier.

3. As the engine speeds up, the flyweight is

forced outward by centrifugal force and the de-

compression pin moves down so that it no lon-

ger opens the exhaust valve.

4. When the engine is stopped, engine speed

drops and the flyweight pulls in and the decom-

pression pin moves up. The pin opens the ex-

haust valve again releasing compression.

The most common cause of problems with this sys-

tem is a faulty spring, the spring may be too long or it

may not be connected. A spring that is too long will

reduce the decompression cutoff speed. Make sure

that the spring is properly attached. If a problem

with the cutoff speed is still suspected, replace the

spring.

CT-1121s

CAMSHAFT

ENGINE START POSITION

ENGINE RUNNING POSITION

DECOMPRESSION

PIN

TAPPET

FLYWEIGHT

SPRING

CAM GEAR

FIGURE 10-38. COMPRESSION RELEASE SYSTEM

Loading...

Loading...