8-23

Checking and Adjusting Regulator Lock-off

Pressure:

Lock-off pressure is determined as fol-

lows by pressurizing the back (vent) side of the reg-

ulator diaphragm to simulate carburetor venturi

vacuum:

1. Connect the regulator inlet (Figure 8-18 on

Page 8-22) to a source of air pressure regu-

lated to 11 inches WC (280 mm WC).

2. Disconnect from the carburetor the LPG supply

hose, which comes from the regulator.

3. “T” in two hoses to the end of the hose con-

nected to the regulator vent fitting (3/8 inch

I. D.). Use one hose to measure pressure by

connecting it to an inclined manometer that

reads 0 to 2 inches WC (0 to 50 mm WC) and

the other to provide the test pressure.

4. Attach a soap bubble to the end of the LPG

supply hose which was disconnected from the

carburetor. While reading the pressure indi-

cated by the manometer and watching the

soap bubble, blow lightly into the hose being

used to pressurize the regulator. Regulator

lock-off pressure is the minimum pressure that

will cause air to flow through the regulator, as

indicated by the expanding soap bubble. (At

first the soap bubble may expand due to dia-

phragm movement but will stop expanding if air

is not flowing through the regulator.)

CAUTION

If this is a bench test of the reg-

ulator, make sure the diaphragm is in a ver-

tical plane (as in the genset), otherwise the

weight of the diaphragm will cause erro-

neous readings of lock-off pressure.

•

For Gensets Beginning Spec E:

Replace the

demand regulator assembly if the lock-off pres-

sure does not fall between 0.10 and 0.30 inch-

es WC (2.5 and 7.6 mm WC).

•

For Gensets Prior to Spec E:

Adjust lock-off

pressure as follows:

• If the lock-off pressure is greater than 0.30

inches (7.6 mm) WC, loosen the lock nut

on the lock-off adjusting screw and back

out the screw (counterclockwise) until the

lock-off pressure falls between 0.10 and

0.30 inches WC (2.5 and 7.6 mm WC). Set

the adjusting screw locknut and test lock-

off pressure again. Repeat the procedure

if necessary.

• If the lock-off pressure is less than 0.10

inches WC (2.5 mm WC), loosen the lock

nut on the lock-off adjusting screw and turn

in the screw (clockwise) until the lock-off

pressure falls between 0.10 and 0.30 inch-

es WC (2.5 and 7.6 mm WC). Set the ad-

justing screw locknut and test lock-off

pressure again. Repeat the procedure if

necessary.

• Replace the demand regulator if it contin-

ues to leak after lock-off pressure adjust-

ments have been attempted.

Priming Solenoid Test:

Upon completing the lock-

off pressure test, energize the priming solenoid by

connecting battery positive (+) to the orange lead

and battery negative (–) to the green lead. Replace

the regulator assembly if the priming solenoid does

not cause the regulator to open.

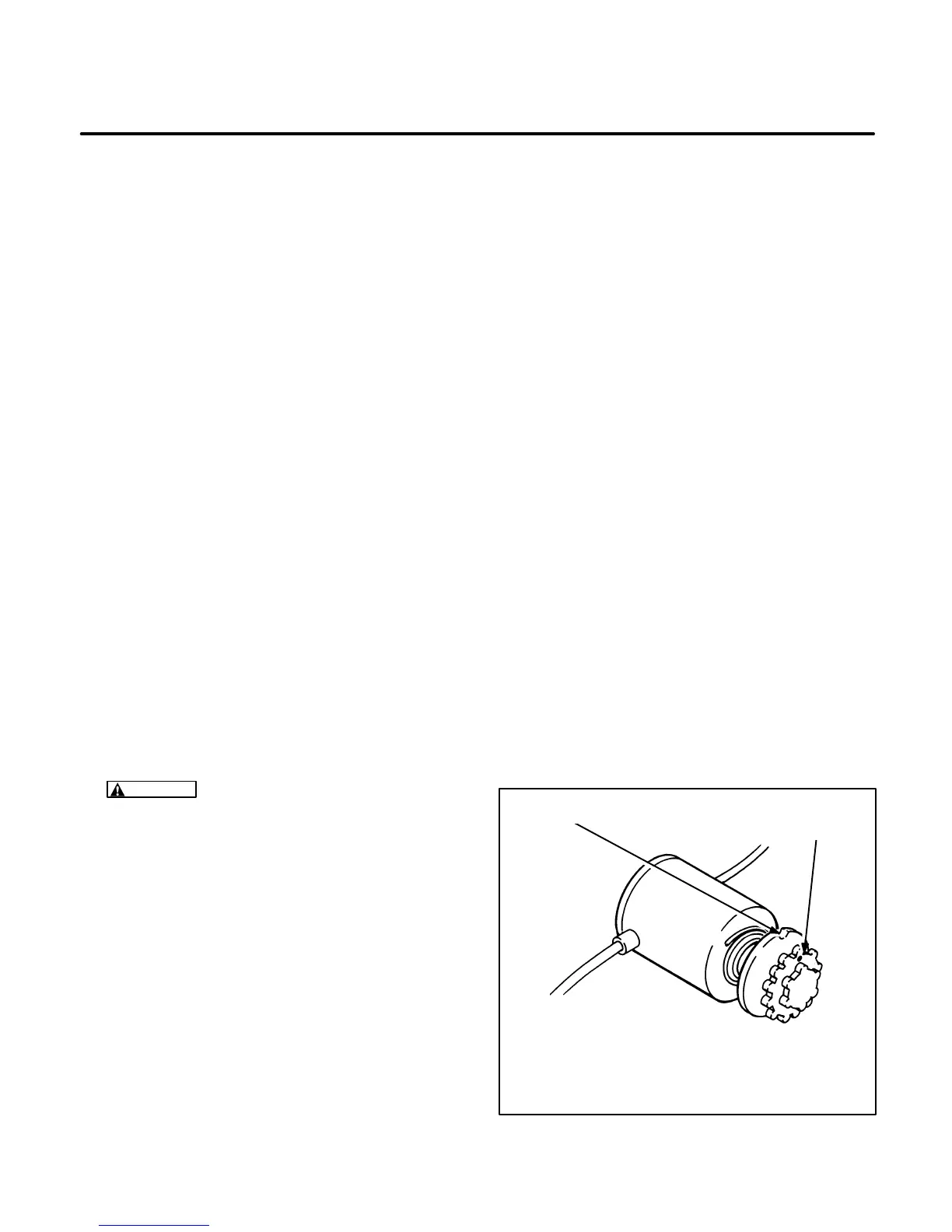

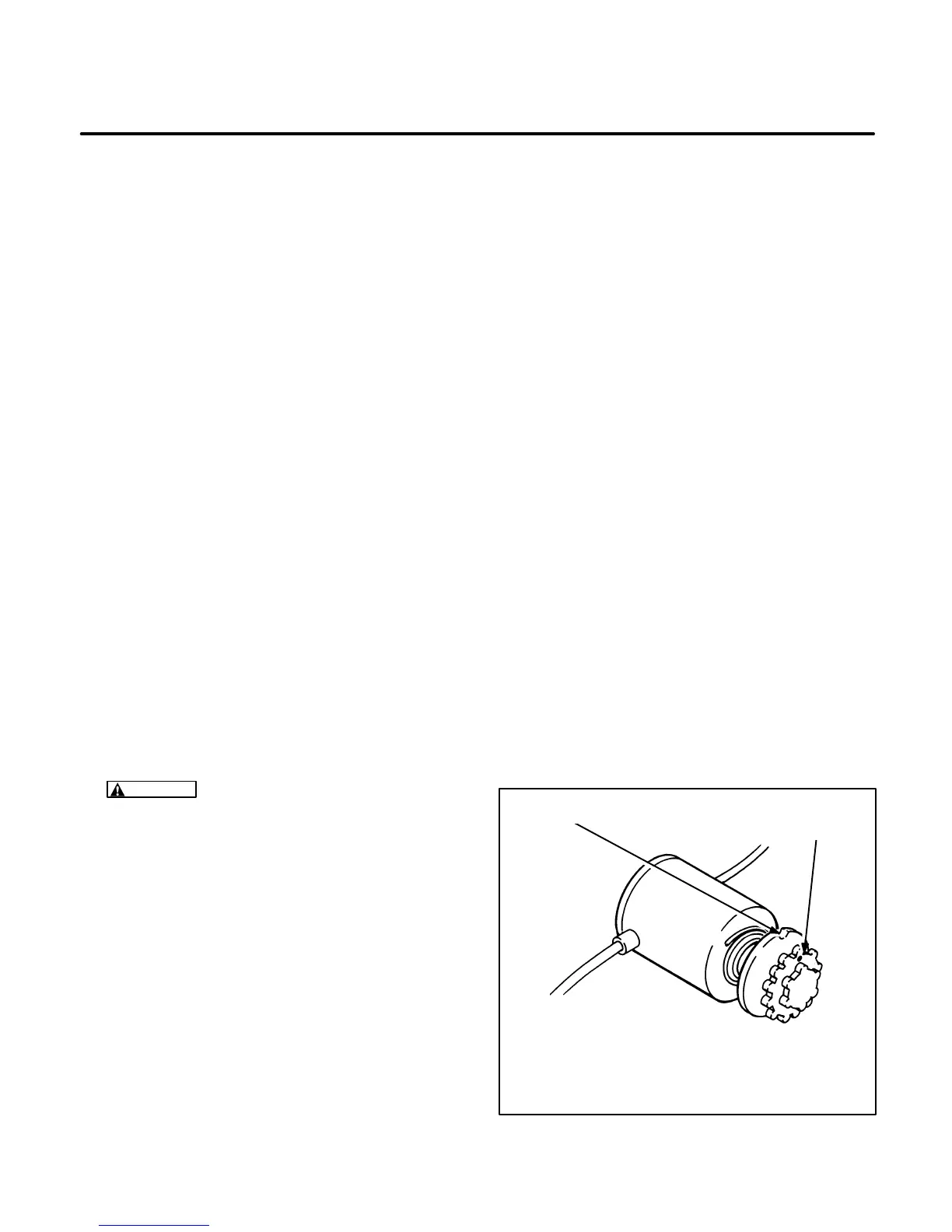

Priming Solenoid Adjustment:

See Figure 8-19.

If the genset does not start when it is hot, rotate the

dial counterclockwise—the fuel mixture could be

too rich. If the genset does not start when it is at am-

bient temperature, rotate the dial clockwise—the

fuel mixture could be too lean.

Adjust the primer solenoid by holding on to the metal disk

and rotating the red dial. Turn the dial clockwise to obtain a

richer mixture and counterclockwise to obtain a leaner

mixture.

METAL DISK RED PLASTIC

DIAL

FIGURE 8-19. AUTOMATIC PRIMING SOLENOID

Loading...

Loading...