10-8

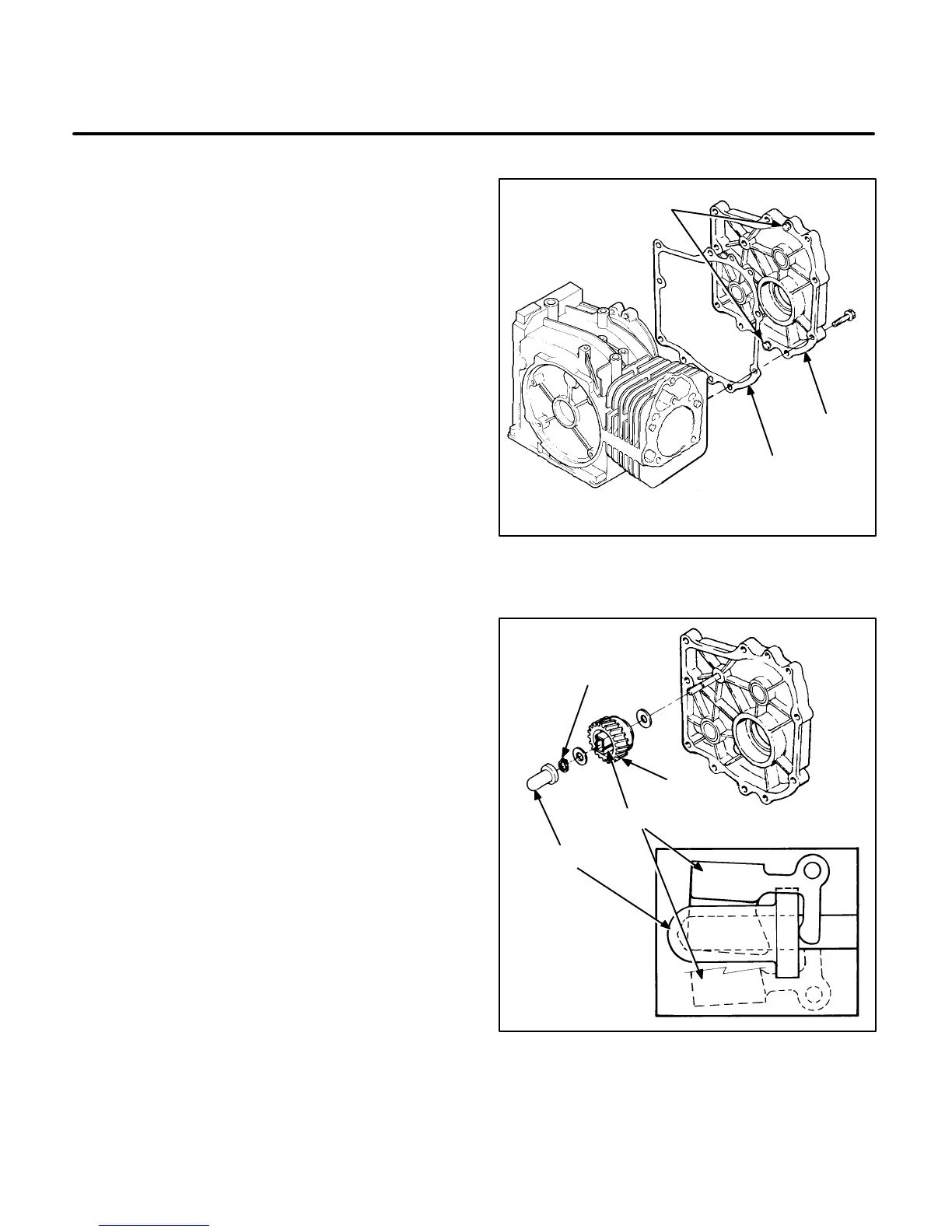

CRANKCASE COVER

1. The crankcase cover is located in two places

with dowel pins (Figure 10-13). Do not attempt

to pry the crankcase cover off or damage can

result. Remove the crankcase cover mounting

bolts. Hold the crankcase cover and lightly tap

the end of the crankshaft with a plastic ham-

mer.

2. Remove the crankcase cover very carefully to

prevent the shaft from scraping the lip surface

of the oil seal.

3. Remove and tag shims from the crankshaft,

camshaft, and balancer shaft. Shim thick-

nesses differ and they must be reassembled in

their original positions.

4. Make sure the governor shaft is properly posi-

tioned when installing the cover. Use a new

gasket and clean the crankcase cover and the

engine block gasket mating surfaces. Place

crankcase cover in position and secure all bolts

in a star pattern to the specified torque (see

Section

4.

Torque Specifications

).

GOVERNOR

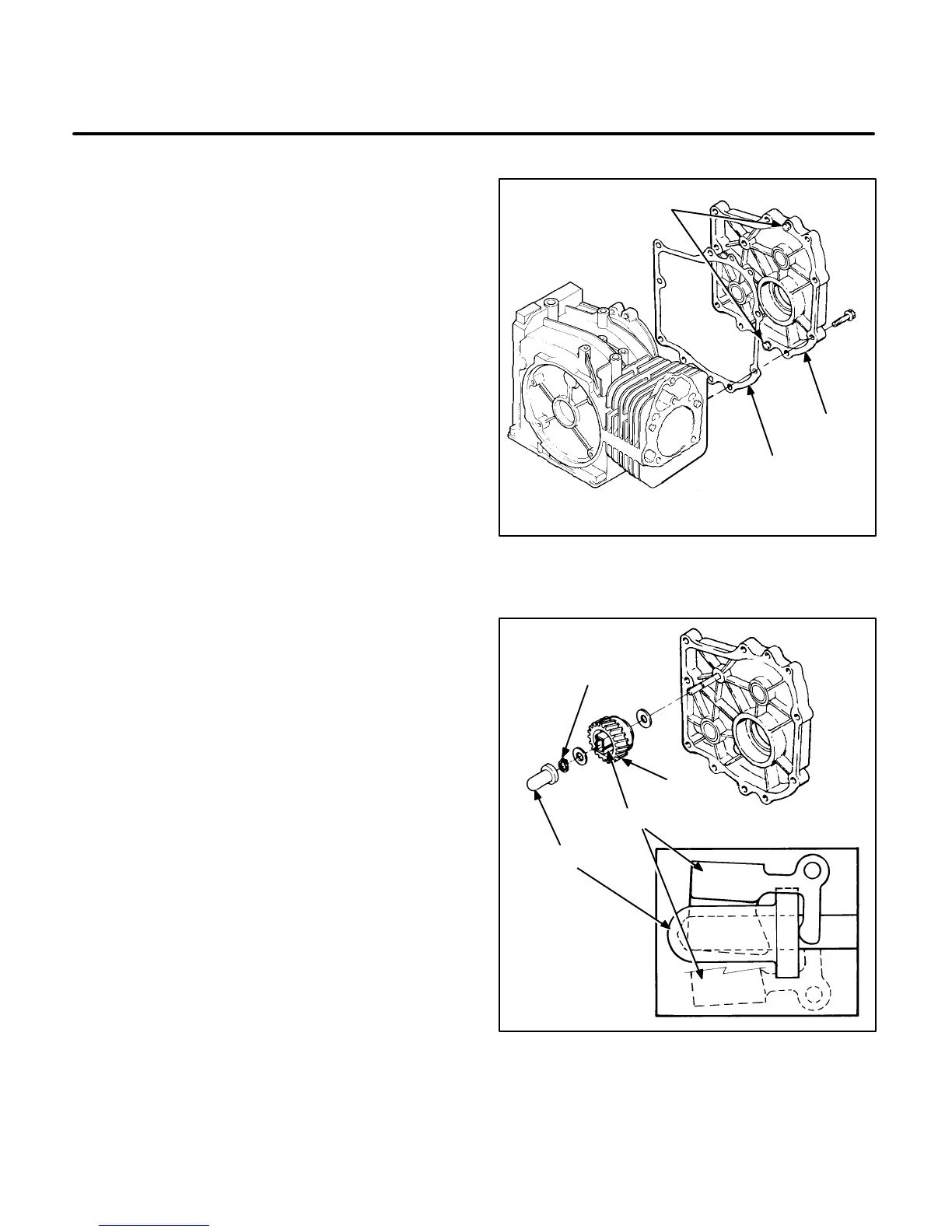

With the crankcase cover removed, the governor

can be inspected or disassembled for service. The

governor assembly must spin freely on the center

pin without excessive looseness or wobble. Sleeve

tip wear is the most common cause of governor fail-

ure. Check for flat spots on the sleeve tip. If the gov-

ernor sleeve, gear, or flyweights are worn or other-

wise damaged, replace them.

To disassemble, remove the snap ring from the gov-

ernor center pin and slide the governor gear assem-

bly off the mounting shaft. Be careful not to lose the

outer washer. See Figure 10-14. To install the gov-

ernor, assemble in reverse order of removal (see in-

set drawing, Figure 10-14, for position of flyweight

and sleeve). The snap ring can be installed by plac-

ing it over the end of the shaft, then use the sleeve to

push it into position. To remove the governor shaft,

remove the retainer clip outside the block and then

lower the governor shaft into the crankcase.

C1113-1s

GASKET

CRANKCASE

COVER

KNOCKOUT

PINS

FIGURE 10-13. CRANKCASE COVER

GEAR

SNAP RING (RUBBER

WASHER BEGIN

SPEC E)

SLEEVE

FLYWEIGHTS

FIGURE 10-14. GOVERNOR

Loading...

Loading...