10-9

CAMSHAFT, TAPPET AND BALANCER

REMOVAL

1. Place the engine cylinder down on a clean flat

surface (Figure 10-15).

2. Carefully pull out the camshaft assembly.

3. Remove the valve tappets. Mark the tappets

because tappet clearances differ and the tap-

pets must be reassembled in their original posi-

tions.

4. Pull out the balancer shaft assembly.

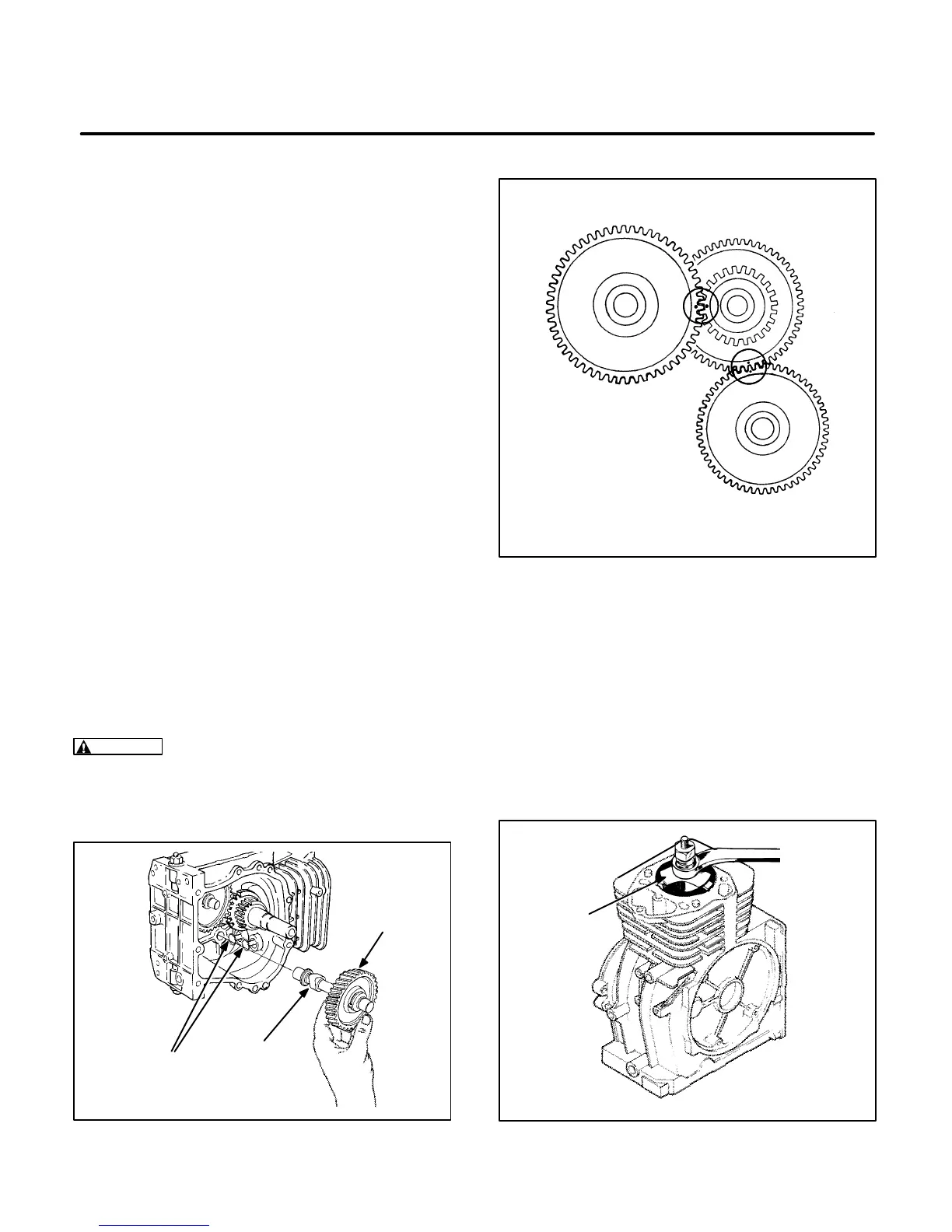

5. For installation, apply oil to the tappets and the

tooth surface of the gears. Align the marks on

the cam gear and crank gear and also on the

balancer gear and crank gear as shown in Fig-

ure 10-16.

PISTON AND CRANKSHAFT

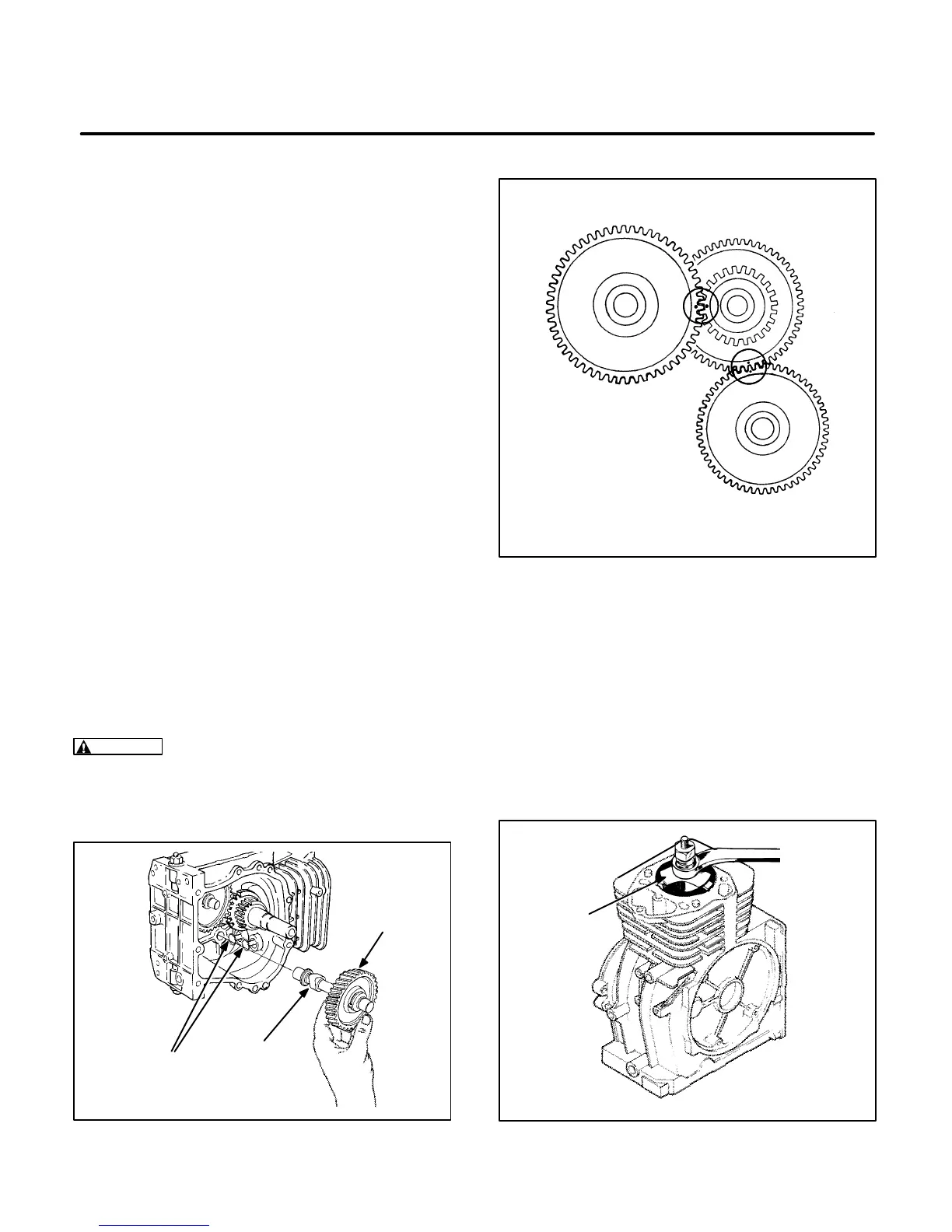

The piston assembly consists of the piston, piston

pin, and connecting rod assembly. After piston re-

moval, all parts must be carefully inspected for

damage and wear before reinstalling. Remove the

carbon from the top of the cylinder bore and check

for a ridge. Remove ridge with a ridge reamer (see

Figure 10-17) before attempting piston removal.

Remove the piston as follows:

CAUTION

Improper use of a ridge reamer can

damage the cylinder bore. Follow tool manufac-

turer’s instructions and be careful when using a

ridge reamer.

C1133-1s

CAM GEAR

TAPPETS

CAMSHAFT

FIGURE 10-15. CAMSHAFT AND TAPPETS

CAM GEAR

BALANCER GEAR

CRANK GEAR

FIGURE 10-16. CAM, CRANK AND BALANCER

GEAR ALIGNMENT

CT1090-1s

RIDGE

REAMER

FIGURE 10-17. REMOVING WEAR RIDGE

Loading...

Loading...