10-17

PISTON AND CRANKSHAFT

INSTALLATION

Lubricate the bearings with engine oil. Slide the

crankshaft into the bearing and add shim(s). Install

the crankcase cover and check to see that the

crankshaft turns freely. Measure the side clearance

of the crankshaft as follows:

Side Clearance of Crankshaft

1. Set a dial gauge, as shown in Figure 10-33,

push the shaft in and measure the clearance.

2. If the side clearance exceeds the allowable lim-

its, adjust with shims.

Remove the crankcase cover and assemble the

piston to the connecting rod. Heat the piston to

300

°F (149°C). Position the piston on the connect-

ing rod. Install the piston pin. Install the lock rings on

each side of the piston pin.

Installing the Piston in Cylinder:

When installing

the piston assembly, observe the markings on the

connecting rod, cap and splasher. See Figure

10-34.

1. Turn the crankshaft to position the crankpin at

the bottom of its stroke.

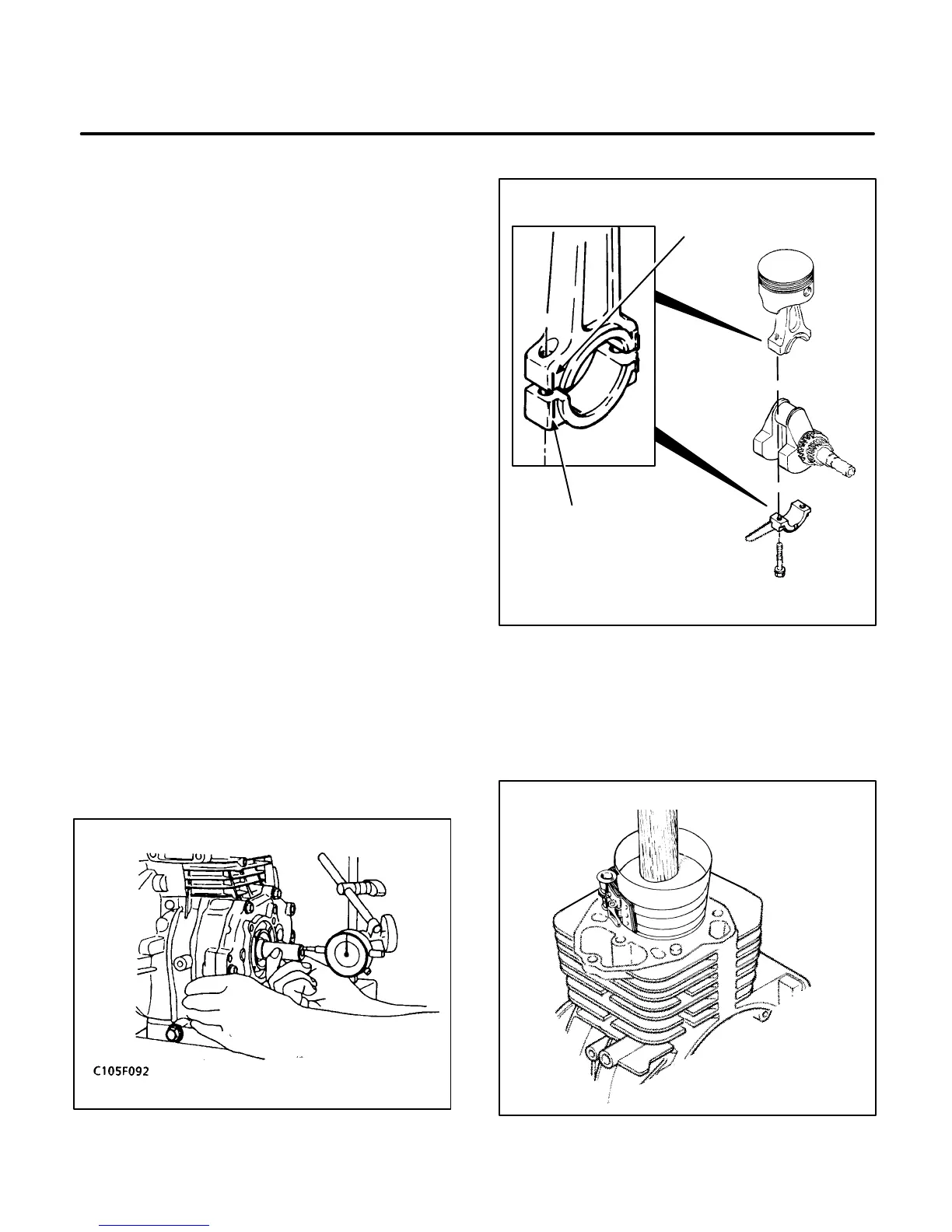

2. Lubricate the piston assembly and inside of cyl-

inder wall. Compress the rings with a ring com-

pressor as shown in Figure 10-35.

3. Tap the piston down into the bore with the han-

dle end of a hammer until the connecting rod is

seated on the crankpin.

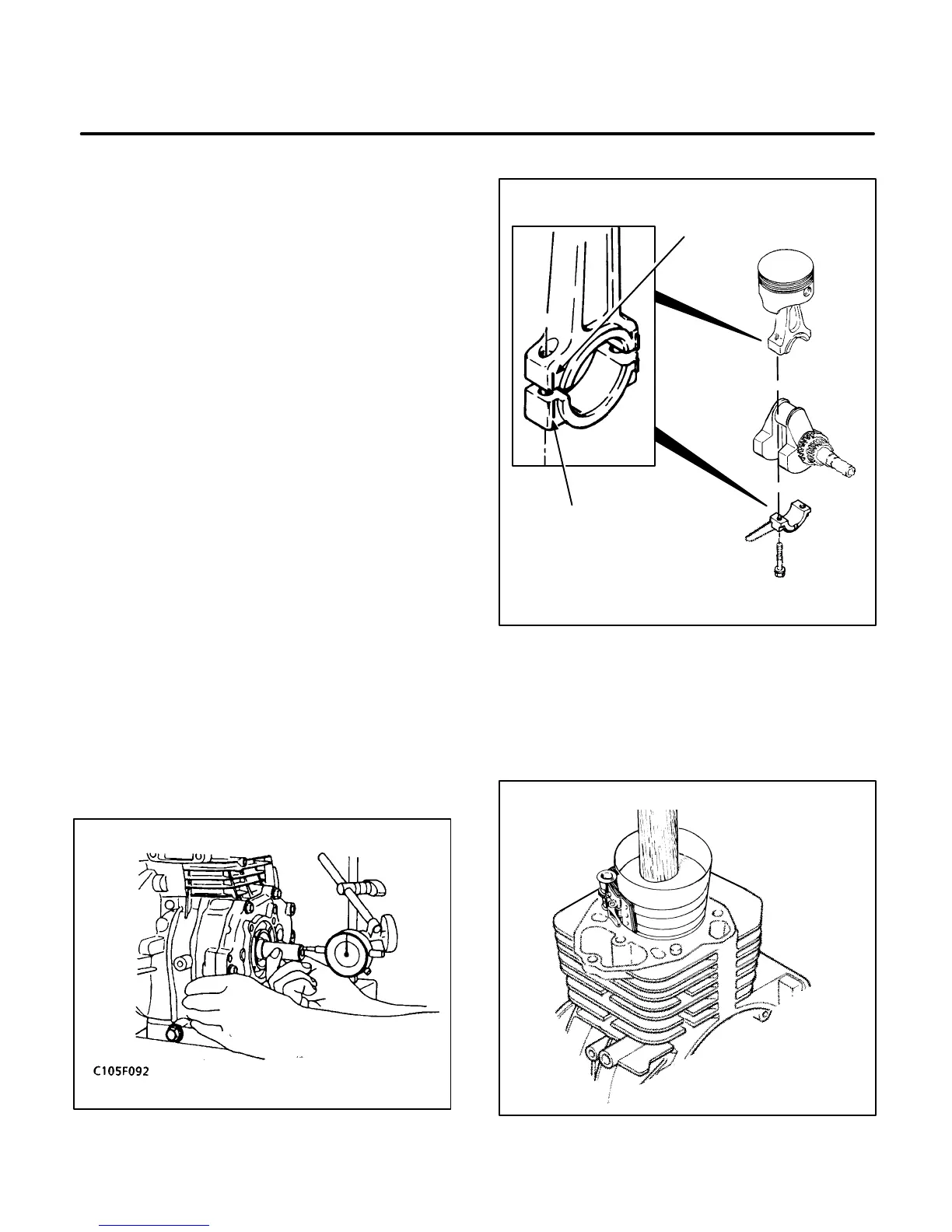

FIGURE 10-33. SIDE CLEARANCE OF

CRANKSHAFT

CT1091-1s

CAP

MARK

CONNECTING

ROD MARK

FIGURE 10-34. ROD CAP ASSEMBLY

CT1066-2s

FIGURE 10-35. INSTALLING PISTON

Loading...

Loading...