10. Engine Block Assembly

10-1

INTRODUCTION

This section covers service procedures for the en-

gine block assembly. A leak down test can be per-

formed to determine the condition of the engine.

Use the procedures in the following section to per-

form the leak down test.

Performing any major service will require genset re-

moval from the vehicle (see

Set Removal Guide-

lines

on Page 5-2). To gain access to the engine

block assembly, the generator and primary engine

systems must be removed. Refer to the previous

sections for the disassembly procedures.

A suggested order of disassembly for the engine

block follows:

1. Oil pan and oil level switch

2. Head cover and breather

3. Rocker arms and push rods

4. Cylinder head, valve springs and valves

5. Crankcase cover, camshaft and balancer

6. Connecting rod and piston

7. Crankshaft and governor lever shaft

LEAK DOWN TEST

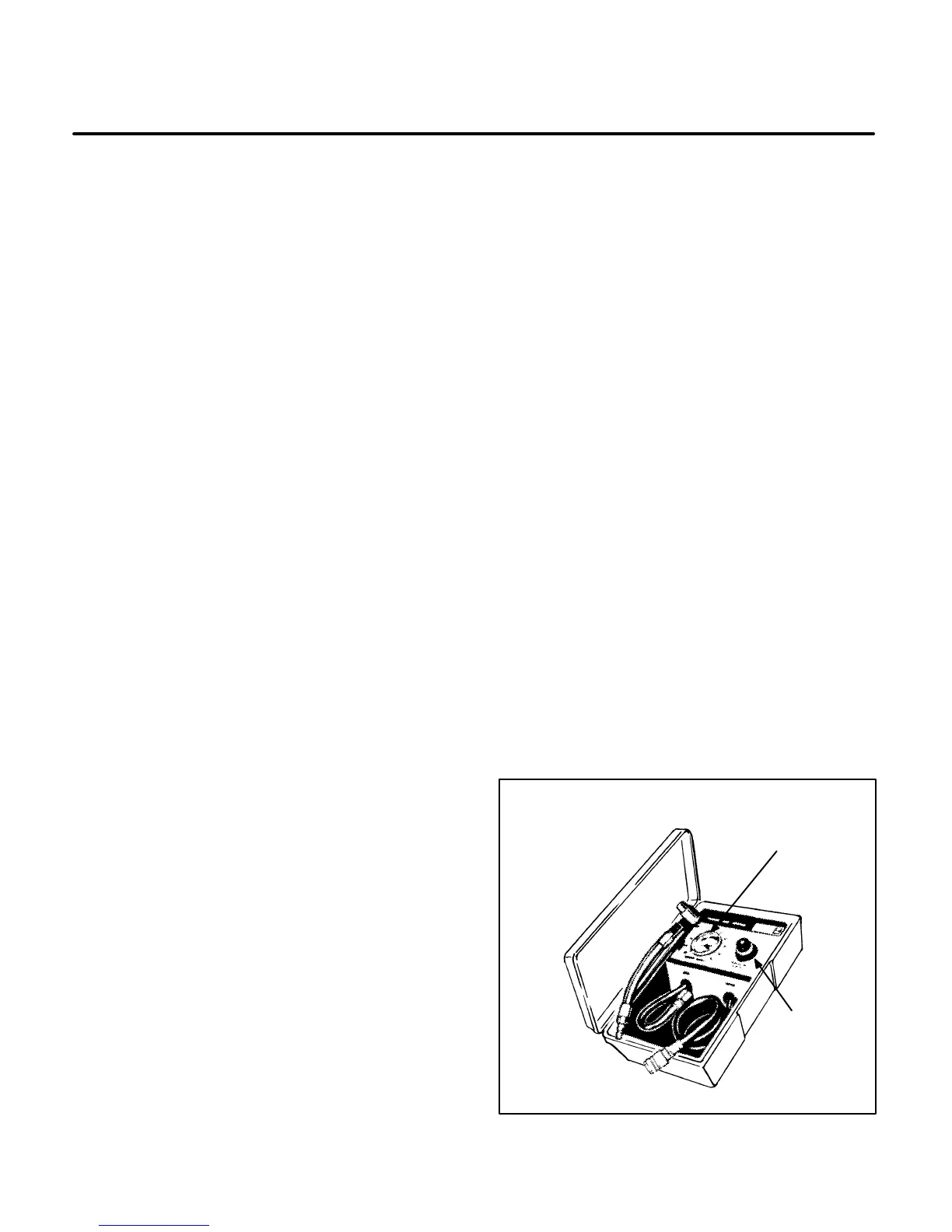

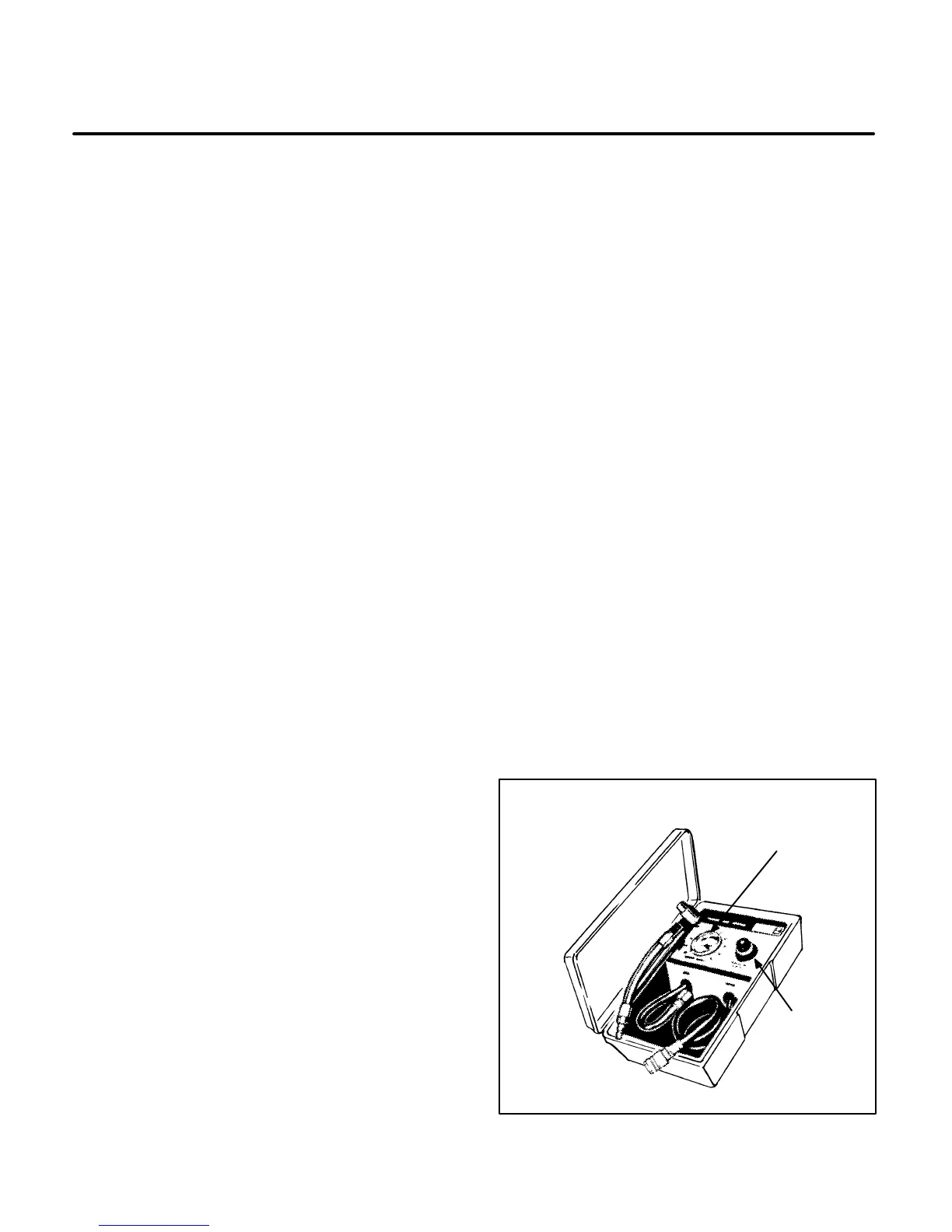

Perform the leak down test if performance problems

or high oil consumption occur and poor compres-

sion is suspected. Follow each of these steps and

refer to the test equipment manufacturer’s instruc-

tions. A typical tester is shown in Figure 10-1.

1. Start the engine and allow it to warm up for ten

minutes. If the engine will not start, continue to

the next step.

2. Disconnect the battery negative (–) cable to

prevent accidental starting and remove the

spark plug.

3. Manually rotate the the engine in the direction

of normal operation by turning the fan hub as-

sembly. Stop turning the engine when it reach-

es top dead center (T.D.C.) on the compression

stroke. T.D.C. can be determined by:

A. Removing the head cover and observing

the valve overlap on the compression

stroke.

B. Feeling compression air escaping the

spark plug hole.

C. Using a tester with a T.D.C. indicator fea-

ture.

4. Connect the tester to shop air and set calibra-

tion. Perform the leak down test according to

the manufacturer’s instructions. Secure the

fan wheel to prevent the piston from moving

during this test.

5. Screw the air fitting into the spark plug hole. At-

tach plug fitting to tester.

6. The tester needle indicates the percentage of

cylinder leakdown. The following describes the

general condition of the engine:

• 0-10 Percent leak down – Excellent condi-

tion

• 10-20 Percent leak down – Normal condi-

tion

• 20-30 Percent leak down – Nearing ser-

vice limit

7. If leakage is greater than 30 percent, the en-

gine could need major service work. With the

tester still connected, listen for air leakage at

the points listed in Table 10-1 on Page 10-2

and note probable cause of the engine prob-

lem.

AIR LEAKAGE

GAUGE

REGULATOR

M1907s

FIGURE 10-1. TYPICAL LEAK DOWN TESTER

Loading...

Loading...