8-8

Magneto Assembly (G2)

The magneto assembly is a noncontact capacitive

discharge (breakerless) type that is mounted to the

generator endbell. As the engine cranks, two per-

manent magnets on the fan hub assembly pass

very close to the magneto inducing a voltage in two

coils in the magneto. One coil charges a capacitor

that discharges a voltage to the coil when triggered.

The other coil powers the circuit that triggers the

charge circuit. The discharge voltage from the mag-

neto (approximately 16 to 60 VAC when measured

with a digital voltmeter) is supplied to the primary of

the ignition coil.

If no spark was seen in the

Ignition Spark Check

on

Page 8-6 and all accessible ignition wiring checks

good, perform the

Magneto Assembly Check,

next

.

Magneto Assembly Check:

Use a known good

(new) ignition coil.

1. Make sure the cranking circuit and battery are

in good condition.

2. Disconnect the low oil level shut down circuit.

Locate the lead from the low oil level switch that

comes out of the top the oil base below the

spark plug. Separate the in-line quick connect

where lead S2 J1-7 connects to the low oil level

switch.

3. Remove the spark plug, reconnect the spark

plug lead and ground the plug side electrode to

bare metal on the engine.

4. Do not touch the plug or plug wire during test-

ing. Crank the engine and observe the plug. A

good spark should be observed. If no spark is

observed, the magneto or wires connected to

the magneto are the most likely cause. Refer to

Section

9.

Generator

for generator disassem-

bly to access the magneto assembly.

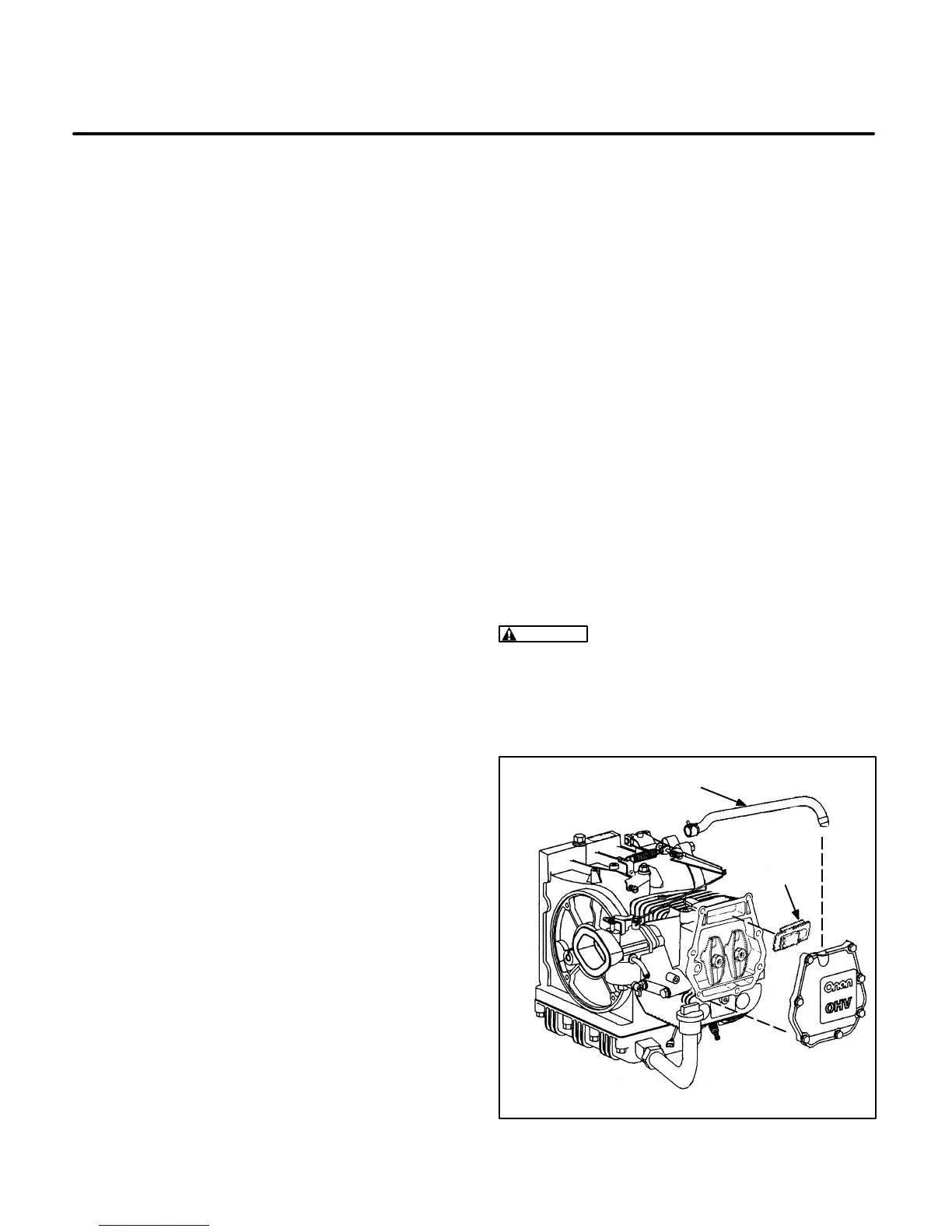

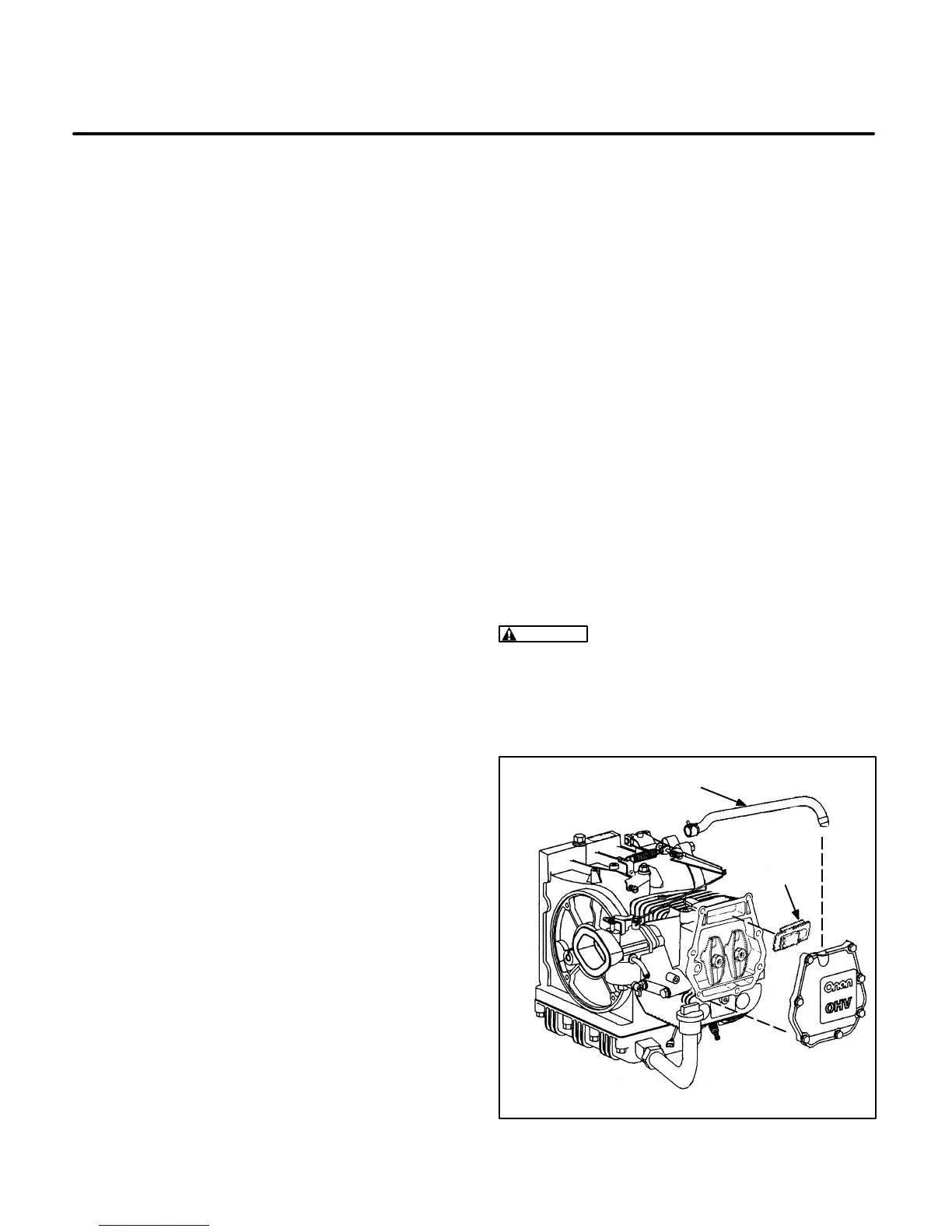

CRANKCASE VENTILATION SYSTEM

The crankcase breather prevents pressure from

building up in the crankcase. It also prevents oil

contamination by removing moisture, gasoline va-

pors and other harmful blow-by materials from the

crankcase. These vapors are routed to the carbure-

tor where they are mixed with the incoming air and

burned in the combustion chamber. A stuck or dam-

aged breather valve can cause oil leaks, high oil

consumption, rough idle, reduced engine power,

and a rapid formation of sludge and varnish within

the engine.

Crankcase Breather Service Procedure

Oil leaks at the seals may indicate that the crank-

case is pressurized. Use the following procedure to

eliminate this condition.

1. Remove the breather tube from the valve cover

(see Figure 8-6).

2. Remove the head cover and breather assem-

bly.

3. Inspect the reed valve. It must be flat with no

signs of creases or other damage. Replace a

defective reed valve. If the breather is dirty,

clean it in parts cleaning solvent.

4. Check the breather tube and air passages for

clogging and clean as required.

WARNING

Most parts cleaning solvents are

flammable and can result in severe personal in-

jury if used improperly. Follow the solvent

manufacturer’s recommendations when clean-

ing parts.

BREATHER HOSE

LS1173-1s

REED

VALVE

FIGURE 8-6. CRANKCASE BREATHER SYSTEM

Loading...

Loading...