8-24

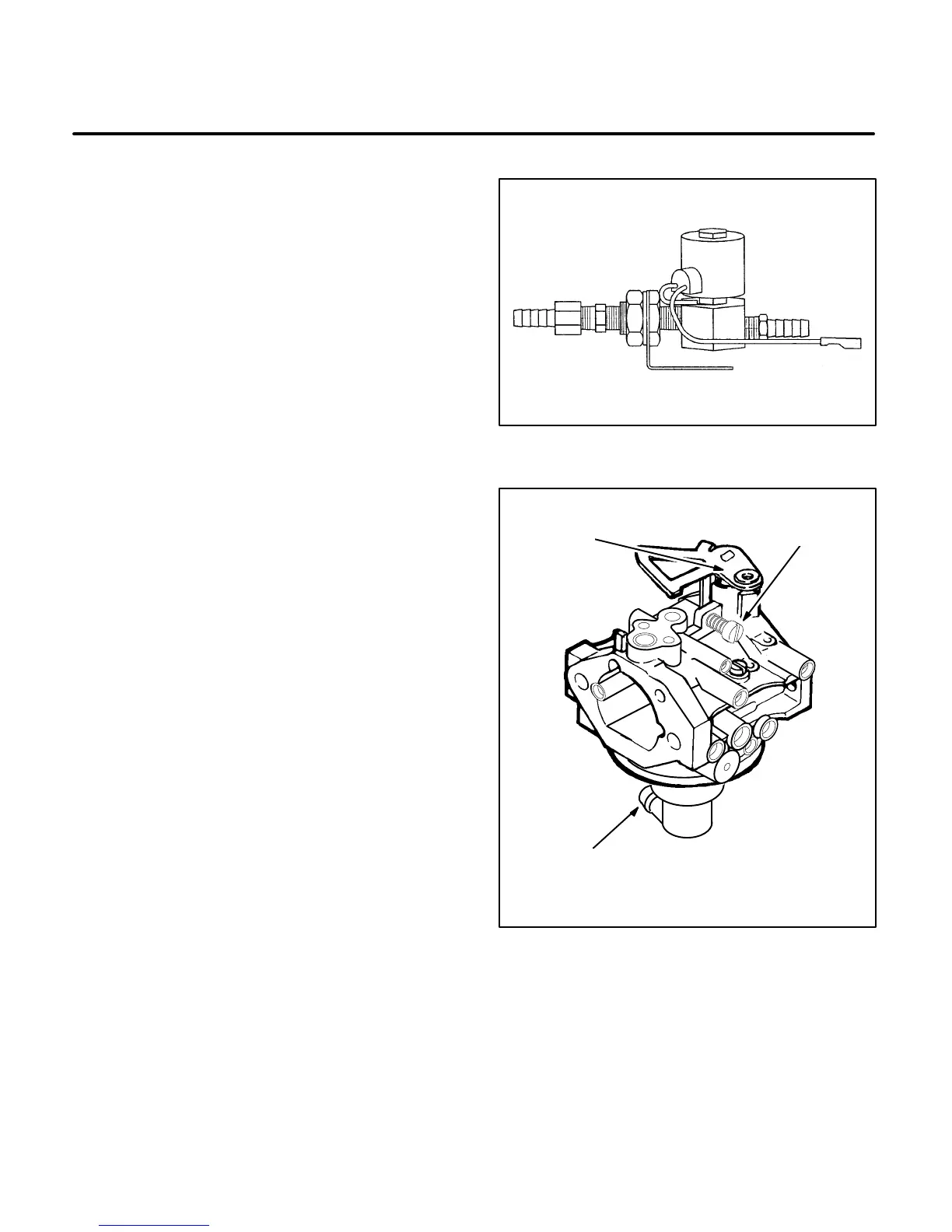

Fuel-Shutoff Solenoid Valve

Leak Test:

See Figure 8-20.

If there is a smell of

gas when the genset is not running, or any other

reason to suspect that the valve is leaking, connect

the inlet of the valve to a source of air pressure regu-

lated to not more than 14 inches WC (356 mm WC)

and disconnect the outlet hose. Replace the sole-

noid if it leaks, as checked by a soap bubble.

Operation Test:

If the genset cranks, but does not

start (first see Section

6.

Troubleshooting

), deter-

mine whether or not the valve is opening. With the

source of air still connected, energize the valve by

connecting battery positive (+) to the top terminal

and battery negative (–) to the grounded terminal.

Replace the solenoid valve if it does not open when

it is energized.

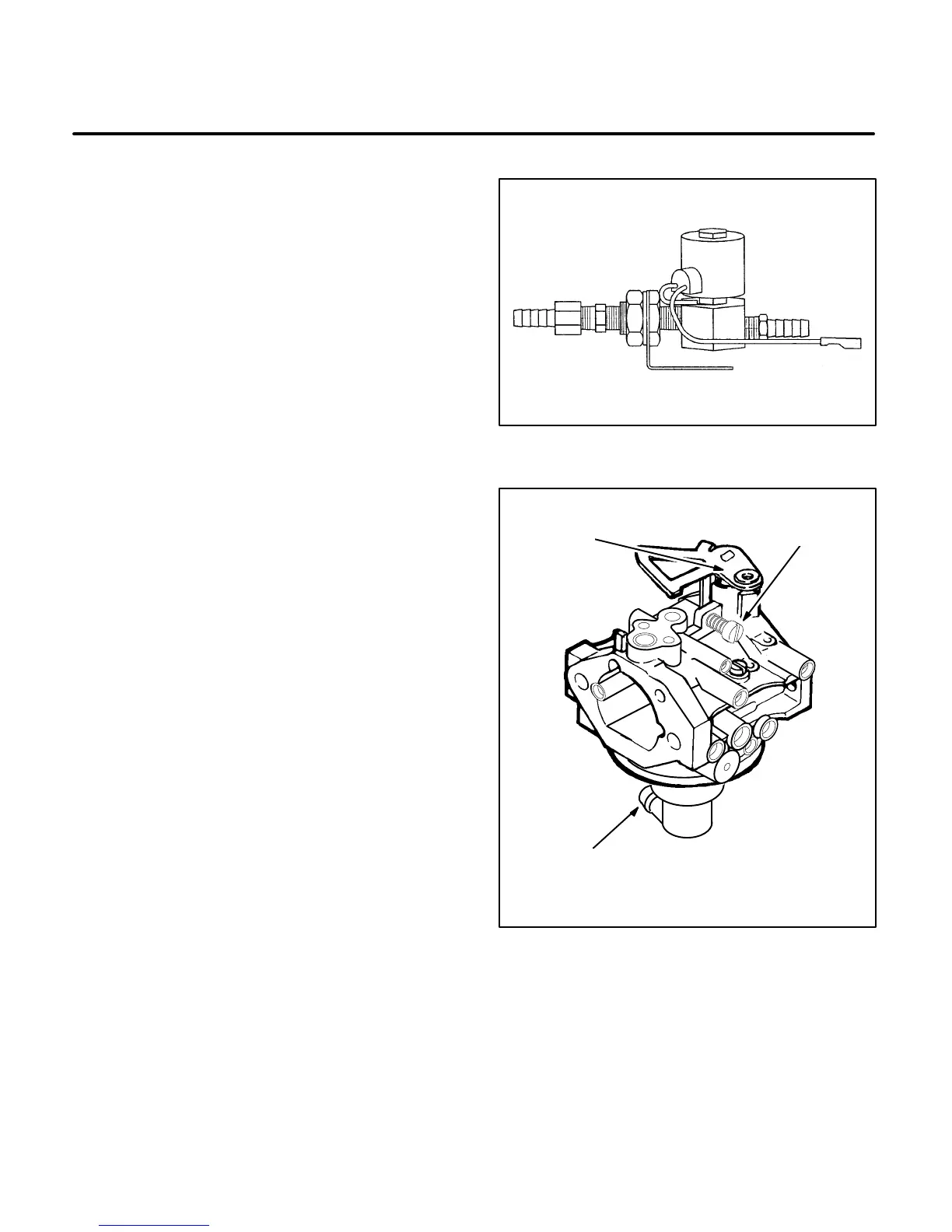

LPG Carburetor (Beginning Spec E)

See Figure 8-21. An LPG carburetor is not likely to

cause problems and should be replaced only after

all other causes have been eliminated (see Section

6. Troubleshooting

). It is not necessary to adjust

fuel mixture. These carburetors are calibrated at the

factory and the adjustments are sealed.

A throttle stop screw is provided for adjusting the

“closed” position of the throttle plate to obtain prop-

er governor response when loads are being discon-

nected. (See

Governor Adjustments

on Page 8-9)

To adjust the throttle stop screw:

1. Connect a frequency meter and start and run

the genset until it has warmed up to normal op-

erating temperature.

2. Disconnect all loads. Pull the governor linkage

toward the front of the genset so that the tang

on the throttle lever bears against the throttle

stop screw. Adjust the stop screw to obtain a

frequency of 44 to 46 Hz on 60 Hz gensets (36

to 38 Hz on 50 Hz gensets).

FIGURE 8-20. FUEL SOLENOID VALVE

GAS HOSE

FITTING

THROTTLE

STOP SCREW

THROTTLE

LEVER

FIGURE 8-21. LPG CARBURETOR

(BEGINNING SPEC E)

Loading...

Loading...