ENGINE

3.35

VALVE SEAT RECONDITIONING, CONT.

10. Insert the valve into its respective guide and lap using

a lappingtool or a section of fuel line connected to the

valve st em.

11. Rotate the valve rapidly back and forth until the cut

sounds smooth. Lift the valve slightly off of the seat,

rotate 1/4 turn, and repeat the lapping process. Do

this four tofivetimesuntilthevalveis fully seated, and

repeat process for the other valve(s).

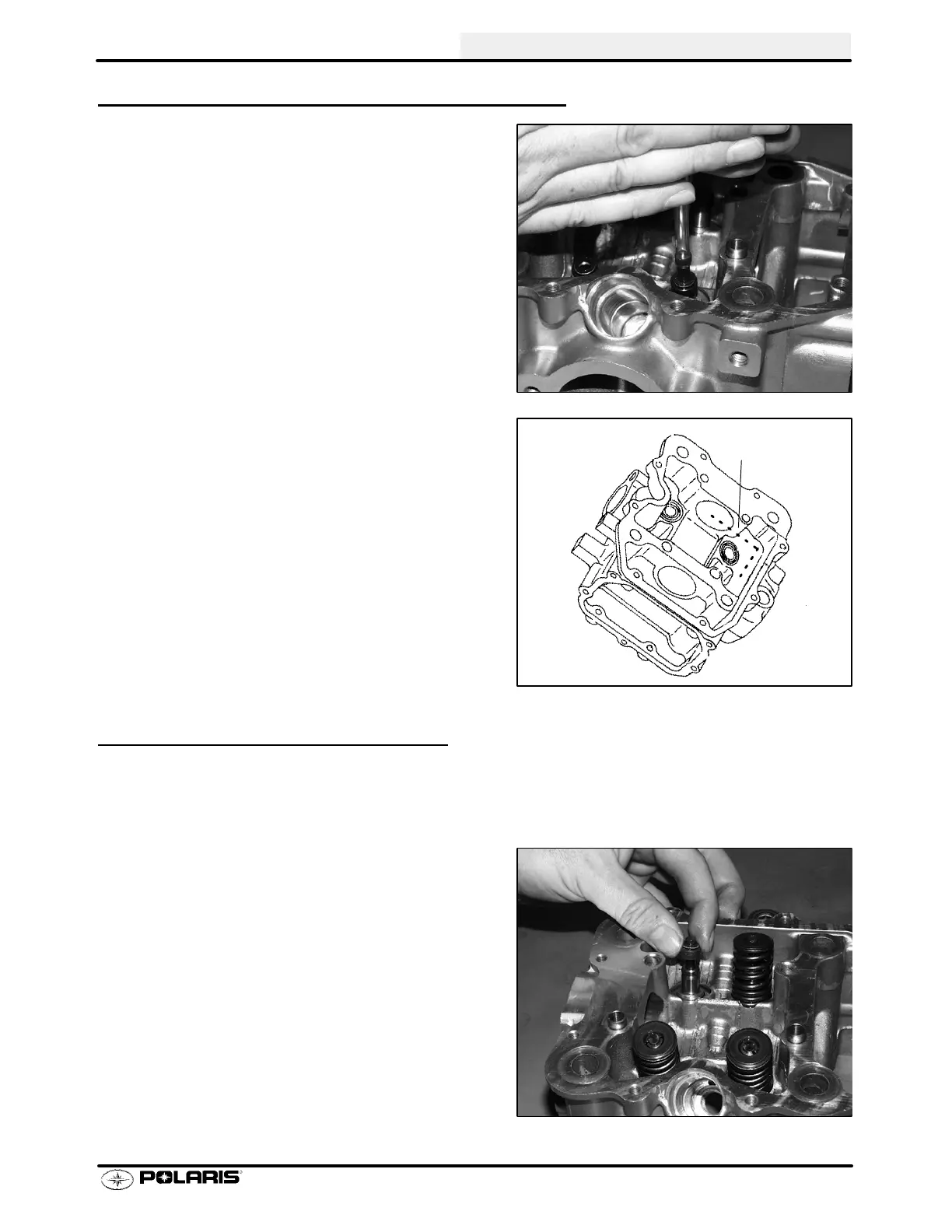

12. Clean cylinder head, valves, and camshaft oil supply

passage (A) thoroughly.

13. If oil passage blind plug was removed, apply 3 Bond

1215 or equivalent sealer to the threads and install,

torquing to 8 ft. lbs. (1.1 kg-m). CAUTION: Do not

allow sealant to enter oil passage.

14. Spray electrical contact cleaner into oil passage and

dry using compressed air.

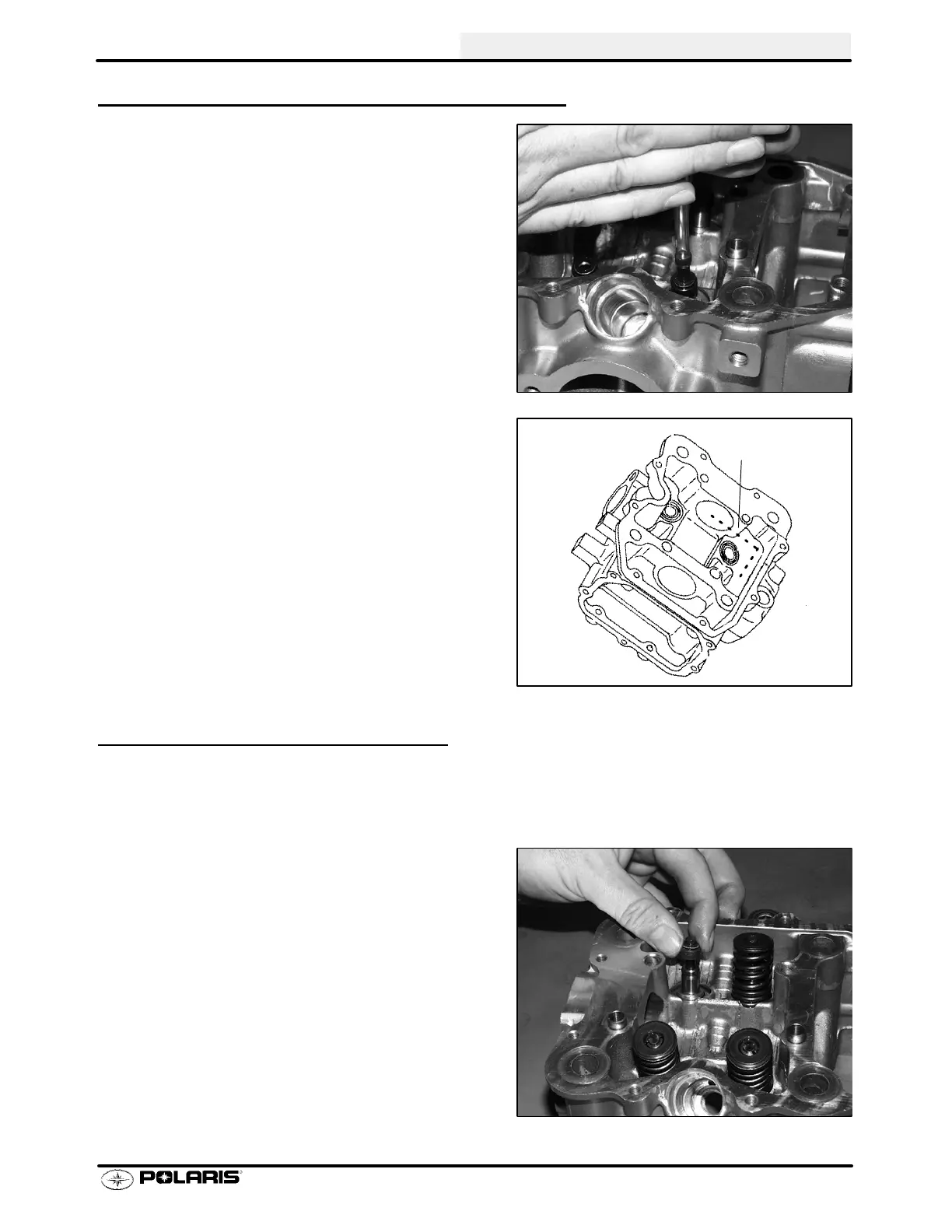

CYLINDER HEAD ASSEMBLY

CAUTION: Wear eye protection during assembly.

NOTE: Assemble the valves one at a time to maintain

proper order.

1. Install new valve seals on valve guides.

2. Apply engine oil to valve guides and seats.

3. Coat valve stem with molybdenum disulfide grease.

4. Install valve carefully with a rotating motion to avoid

damaging valve seal.

A

Loading...

Loading...