CLUTCH

6.21

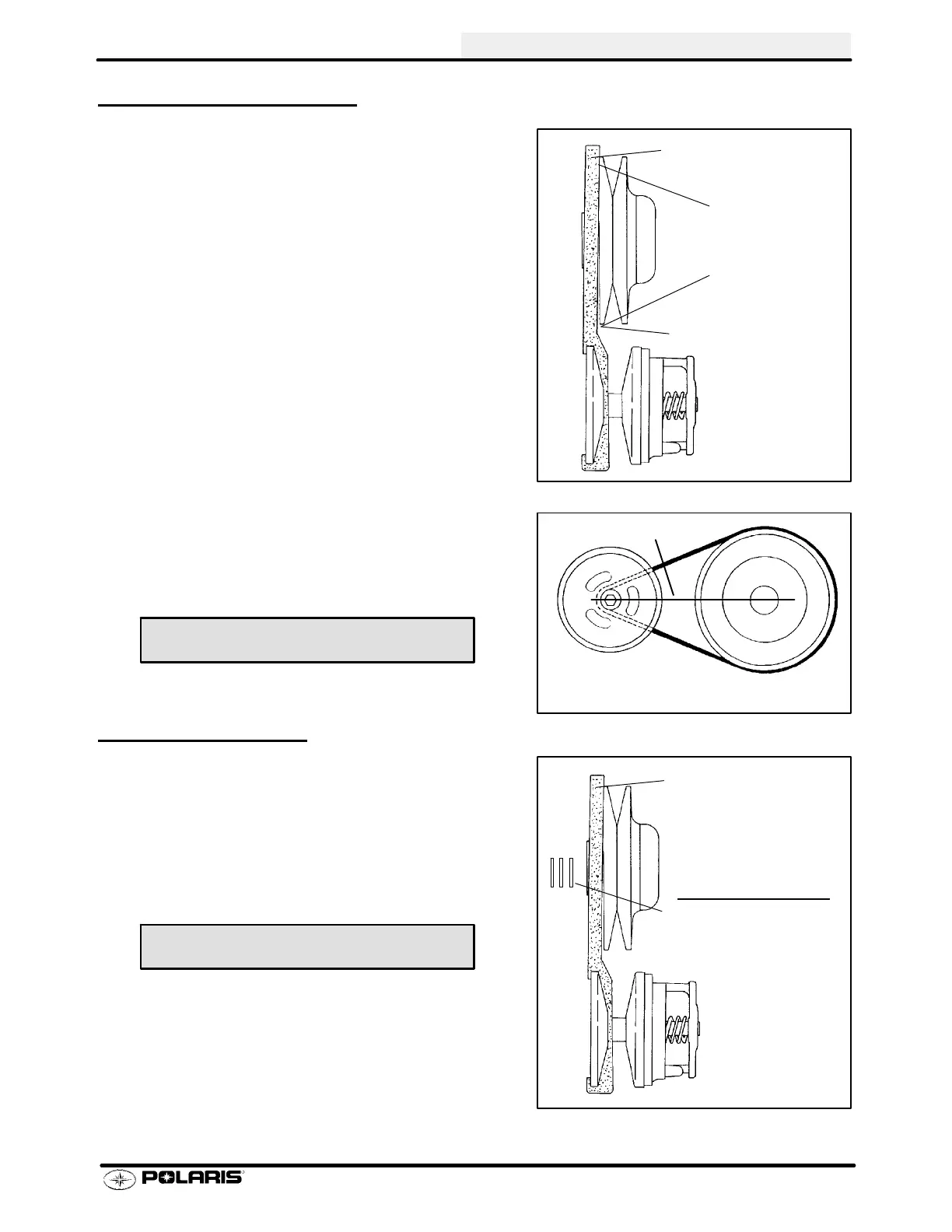

CLUTCH ALIGNMENT

1. Remove belt and install offset/alignment tool as shown.

2. With tool touching rear of driven clutch inner sheave, the

distance at point “A” should be 1/8″.

If the distance is greater than 1/8″ or less than 1/16″,clutch

alignment must be adjusted as follows:

3. Remove drive and driven clutch. See PVT Disassembly,

pages 6.5 - 6.6.

4. Remove PVT inner cover.

5. Loosen all engine mounts. Move front of engine to the

right or left slightly until alignment is correct.

6. T ighten engine mounts and verify alignment is correct.

7. Measure belt deflection and measure offset both above

and below sheave centerlines. Adjust if necessary.

NOTE: On somemodels,minoradjustmentscanbemadeby

adding shims between the frame and front lower left engine

mount to increase the distance at point “A”. If a shim is pres-

ent, it can be removed to decrease the distance at point “A”.

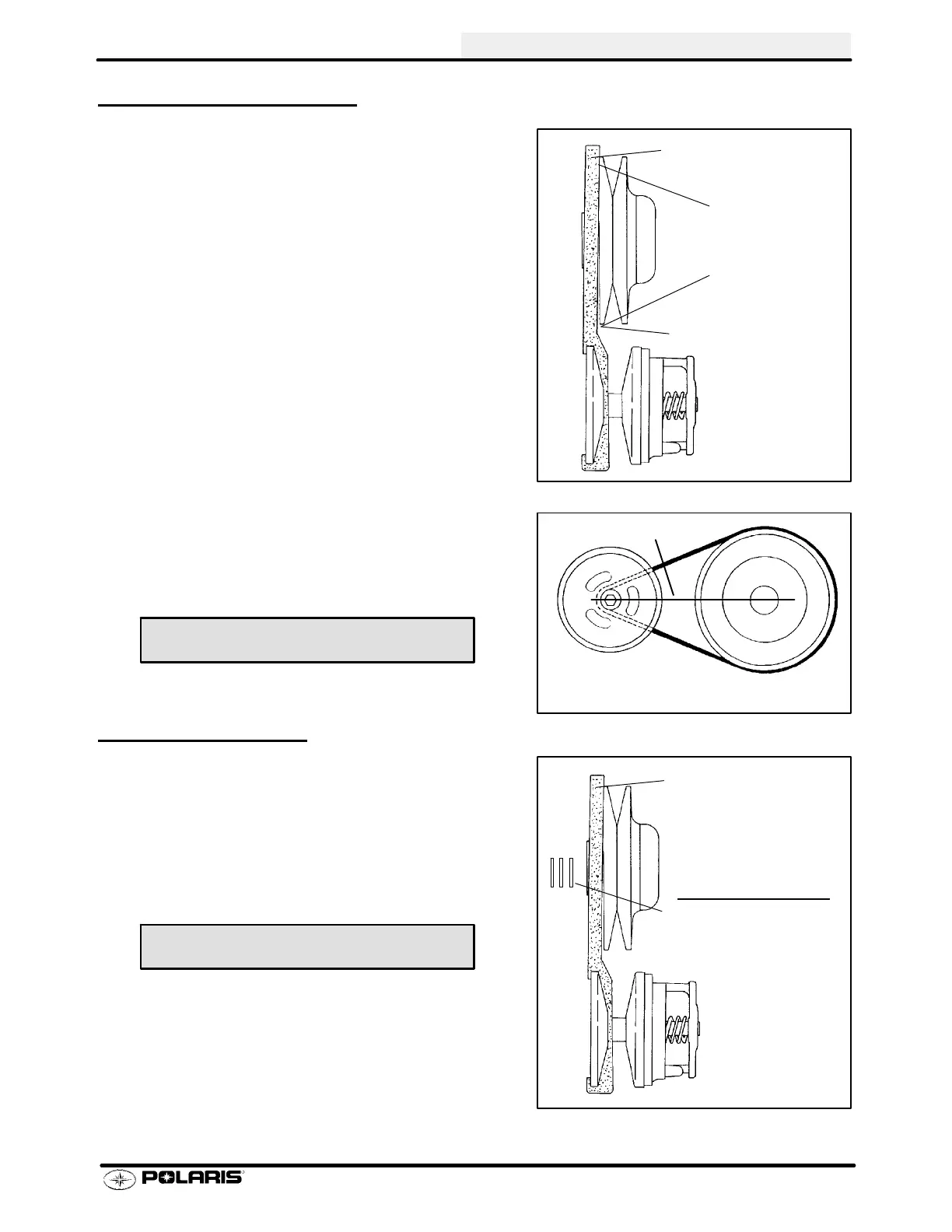

CLUTCH OFFSET

Important: Inspect clutch alignment and center distance be-

fore adjusting offset.

1. Install offset alignment tool as shown.

Offset is correct when rear of tool contacts rear of inner

sheave with driven clutch pushed completely inward on shaft

and bolt torqued. Adjust offset by adding or removing spacer

washers between back of drivenclutch andspacer asshown.

1/8I +0 / -- 1/16

3.2mm +0 / -- 1.6 mm)

Offset Alignment Tool

PN 2870654 - STD

PN 2872292 - EBS

B

A

Center line

Measure offset above and below

centerline

Shim Kit PN 2200126

Offset Alignment Tool

should contact rear edge

of driven clutch sheave

Driven Clutch Offset

To adjust, add or remove

washers from behind the

driven clutch

Spacer W asher PN 7556401

Loading...

Loading...