ENGINE

3.58

COUNTER BALANCER SHAFT END PLAY ADJUSTMENT

1. Make sure all bearings are firmly seated in the

crankcase.

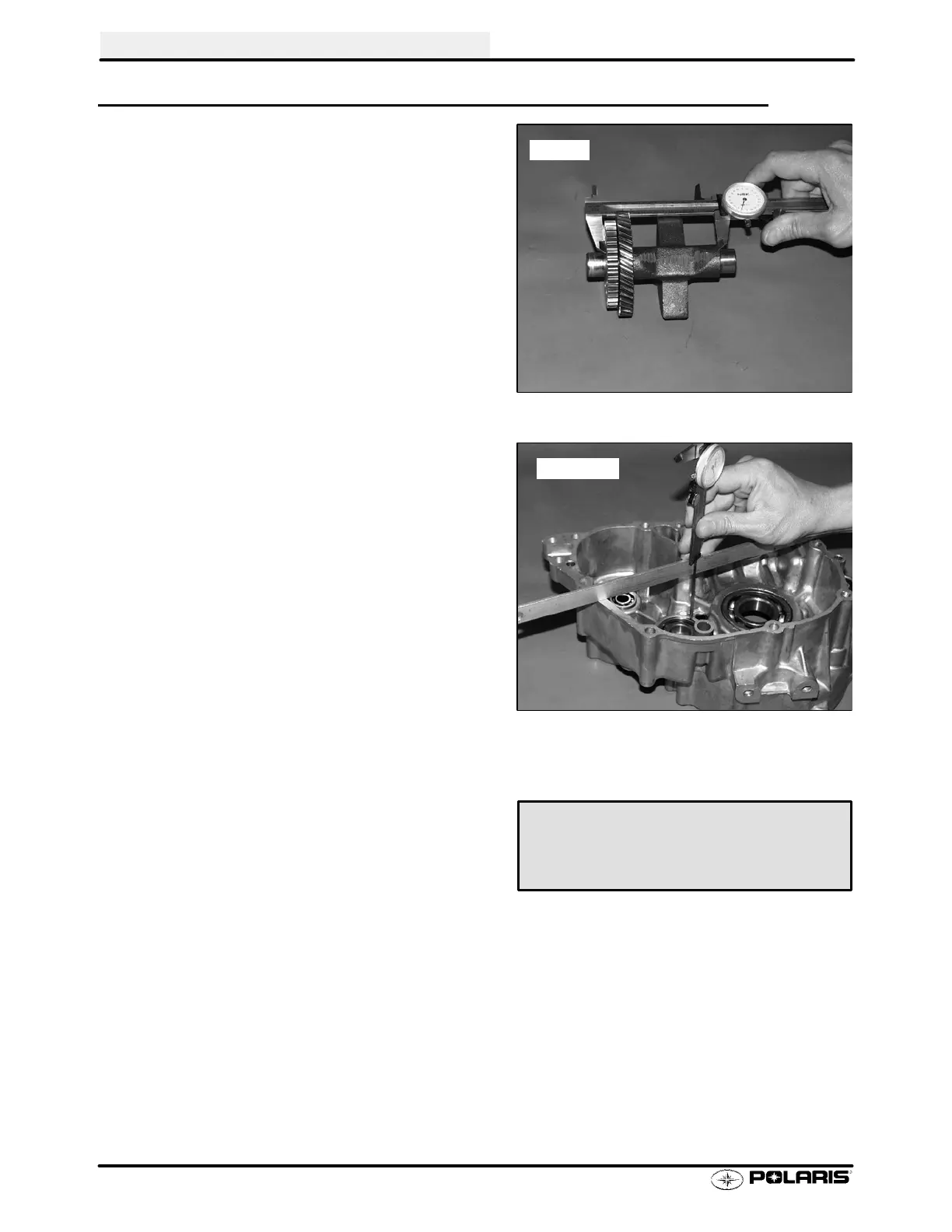

2. Measurethewidthofthecounter balancer shaft at

thebearingseatswithadialcaliper ormicrometer,

and record reading.

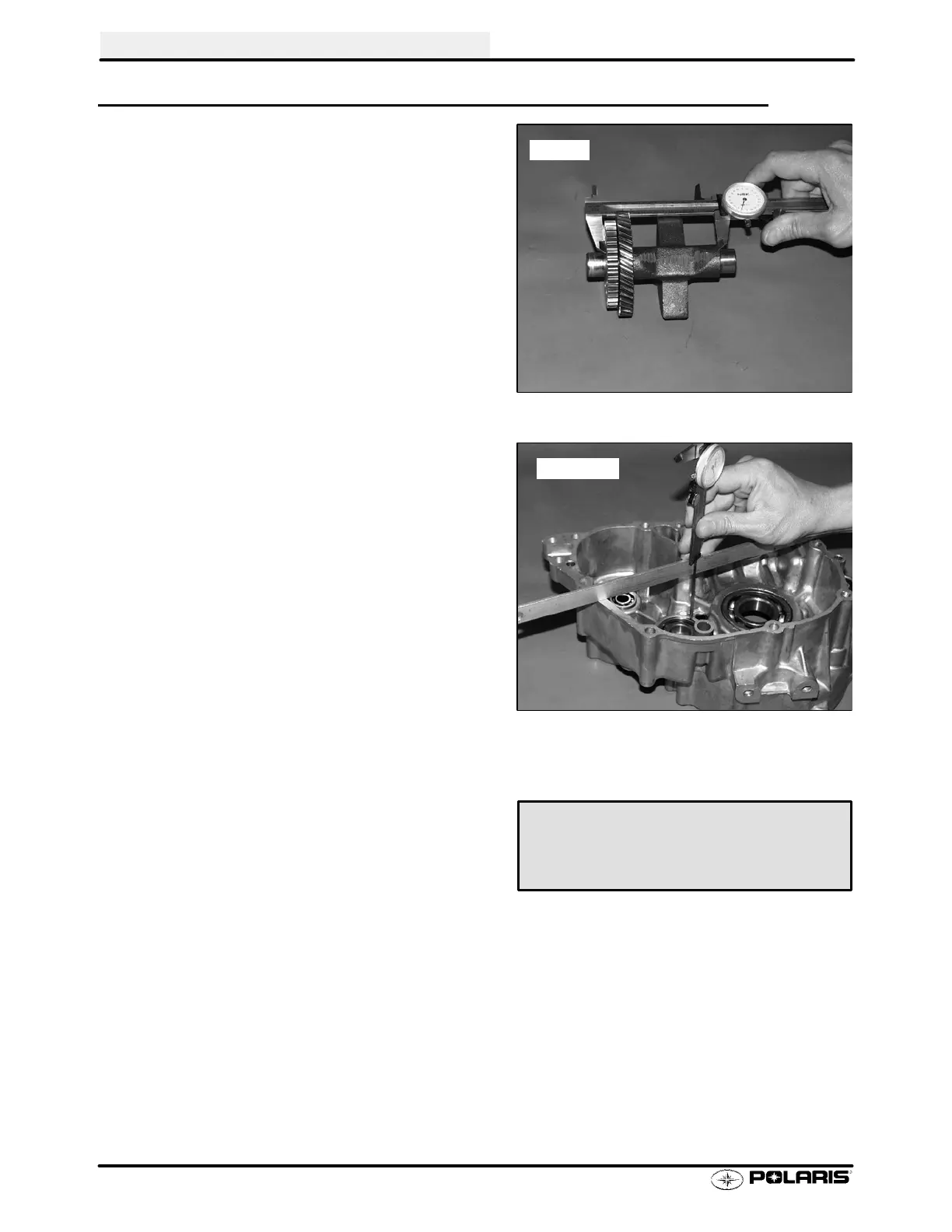

3. Measure the distance from the Mag crankcase

mating surface to the balance shaft bearing using

a dial caliper and a straight edge. Subtract the

thickness of the straightedge and record.

4. Measure the distance from the PTO crankcase

mating surface to the bearing using the same

method outlined in Step 1, 2, and-3.

5. Add the readings obtained in Step 3 and Step 4.

6. Subtract the counter balancer shaft width

measured in step 2 from the figure obtained in step

5.

7. Subtract the thickness of the existing shim from

the result of step 6 to determine if a different shim

isneeded. Theresultmust bewithinthespecified

range listed at right.

Step 2

Step3/4

Counter Balancer Shaft End Play:

.008″-.016″ (.02-.04 cm)

Loading...

Loading...