FINAL DRIVE

7.5

AWD FRONT HUB BEARING ADJUSTMENT

W ARNING

The following bearing adjustments are very important. Incorrect adjustment will increase bearing wear, reduce

braking action, and may affectfront drive hubengagement, which could result inserious personalinjury ordeath.

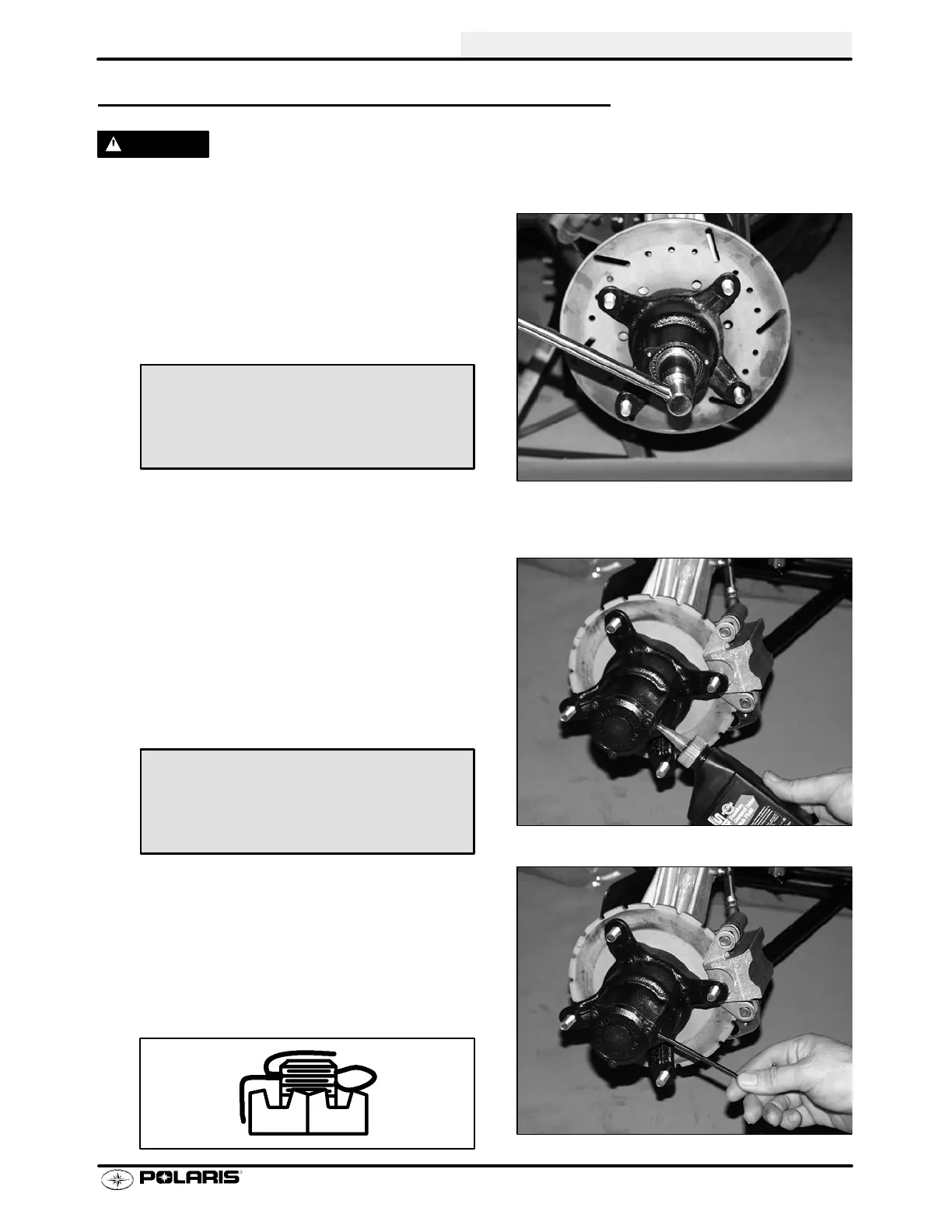

1. Torque spindle nut to 160-170 inch lbs. while

rotating hub continuously.

2. Back off nut 1/2 turn.

3. Rotate axle several revolutions by raising rear of

machine and rotating rear wheels with the

machine in gear.

4. Re-torque hub nut to 108-144 inch lbs.

5. Install cotter pin. Bend each leg of cotter pin

around castle nut in different directions. See

below.

NOTE: If cotter pin holedoes not align, tightenslightly

to align and install pin. Do not exceed 144 in. lbs.

6. Reinstall hub cap.

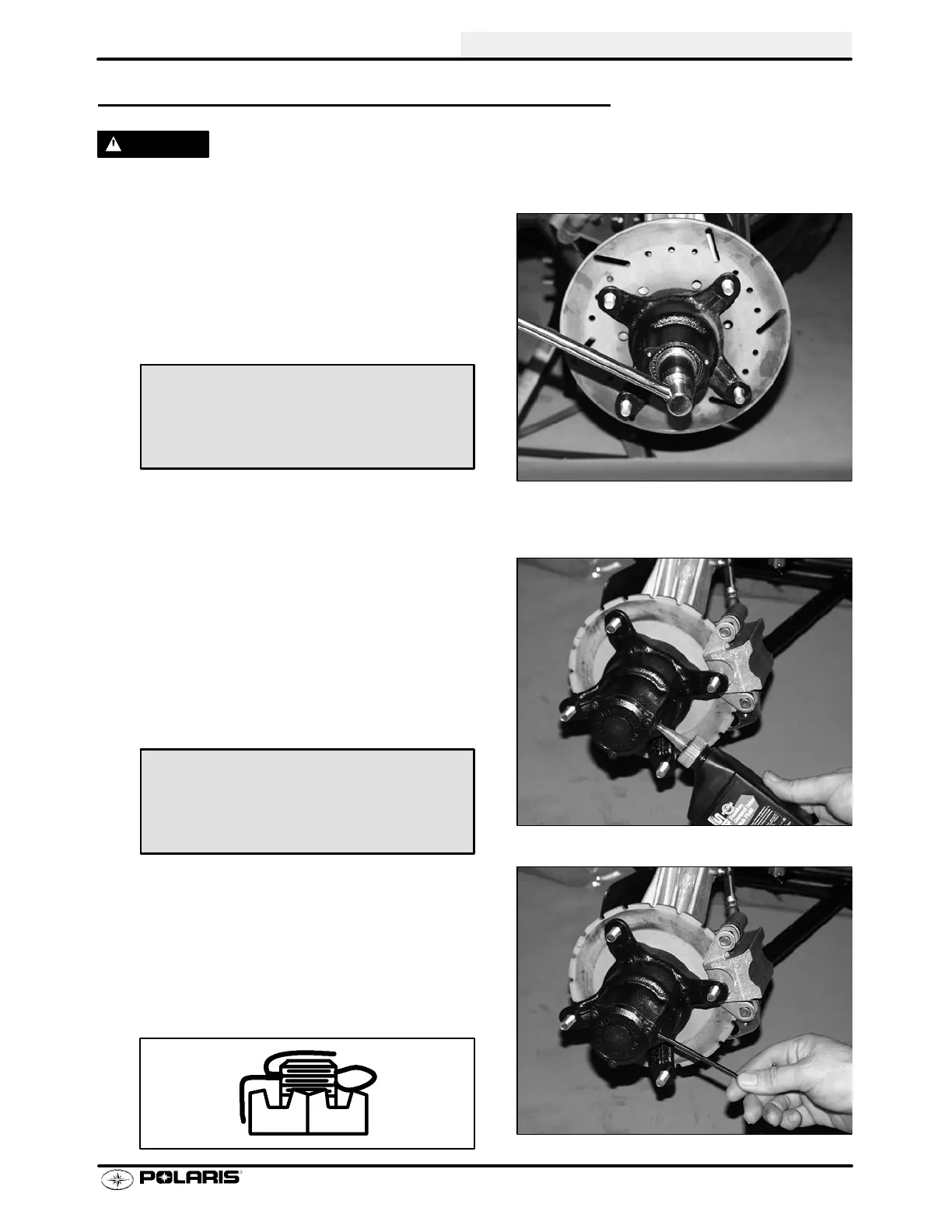

7. Remove fill check plug and rotate hole to either

4:00 or 8:00 position.

8. Fill with Polaris Premium DemandDrive HubFluid

or Type F Automatic Transmission Fluid until fluid

trickles out. NOTE: Do not force the oil into the

hub under pressure. This cancause sealdamage

and leaks.

9. Reinstall plug.

10. Reinstall brakecaliperassembly. Torqueretaining

bolts to 18 ft. lbs. (25 Nm).

11. Reinstall front wheels. Torque retaining nuts to 15

ft. lbs. (21 Nm).

12. Carefully lower vehicle.

13. Field test vehicle for proper operation of brake

system and AWD operation.

Front Spindle Nut Torque:

108-144 in. lbs.

Brake Caliper Retaining Bolt Torque:

18 ft. lbs. (25 Nm)

Premium Demand Drive Hub Fluid

PN 2871654 (8 oz.)

PN 2872277 (2.5 gal.)

Loading...

Loading...