CLUTCH

6.20

DRIVE BELT REMOVAL/INSPECTION, CONT.

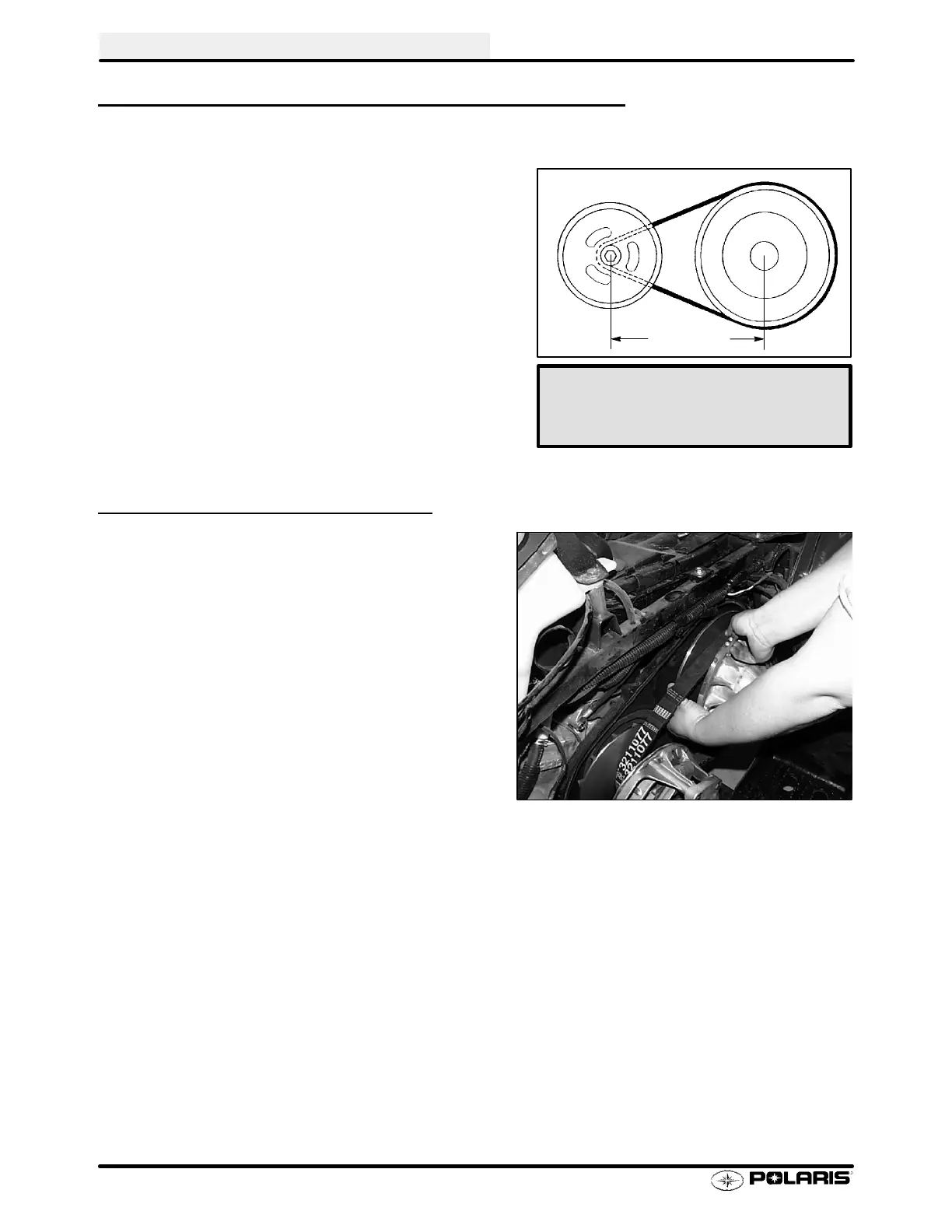

7. Measure belt length withatapemeasure aroundthe

outer circumference of the belt. Belts which

measure longer than nominal length may require

driven shimming or engine adjustment for a longer

center distance to obtain proper belt deflection.

Belts which measure shorter than nominal length

may require driven shimming or a shorter center

distance. Remember, proper belt deflection is the

desired goal -- not a specific center distance.

8. Replace belt if wornpast theservice limit. Belts with

thin spots, burn marks, etc., should be replaced to

eliminate noise, vibration, or erratic PVT operation.

SeeTroubleshootingChart at theendof this chapter

forpossiblecauses. NOTE: Ifanewbeltisinstalled,

check belt deflection.

DRIVE BELT INSTALLATION

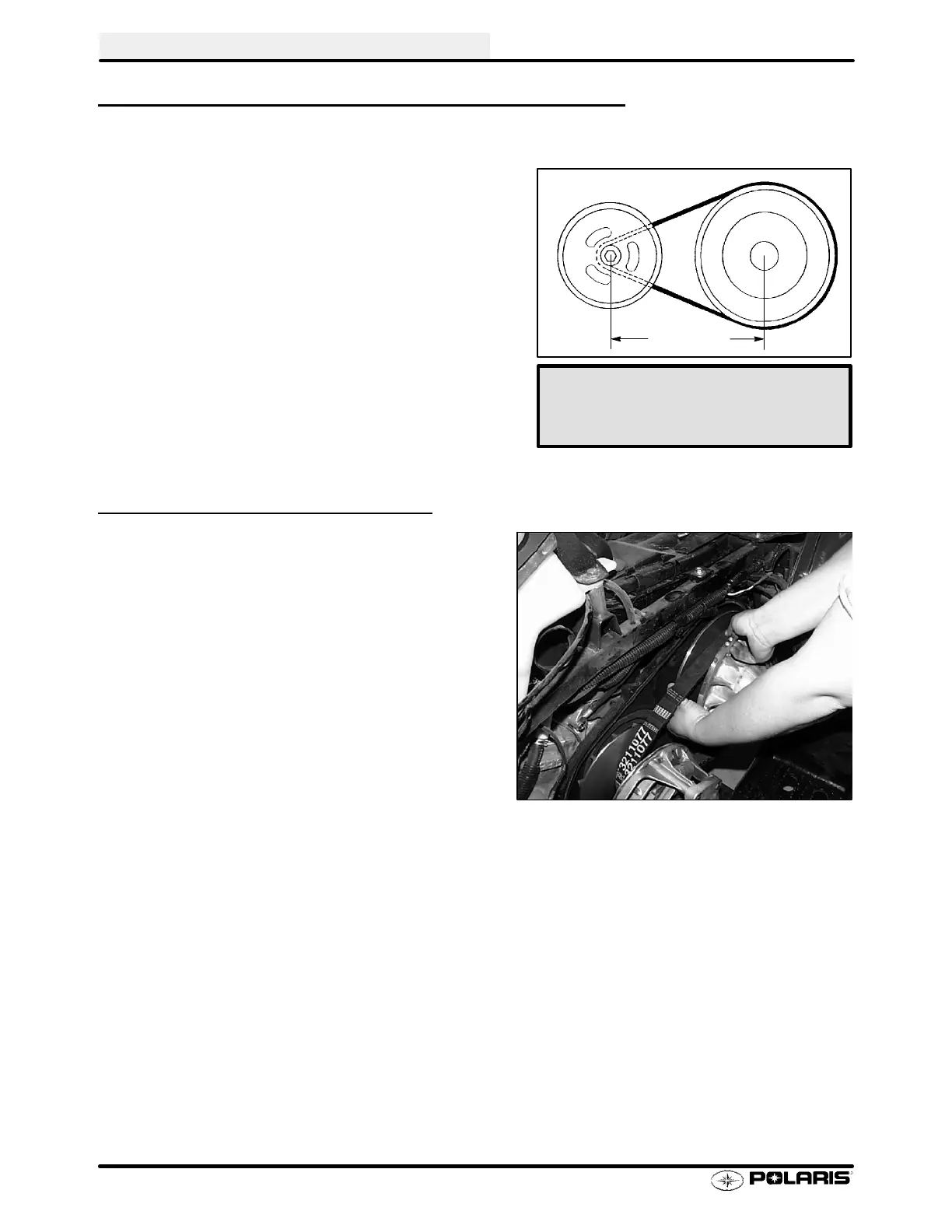

1. Loop belt over drive and over top of driven sheave.

2. While pushing down on top of belt, turn the back or

moveable driven sheave clockwise.

3. The belt then should be ableto be pushed downinto

and between the sheaves.

NOTE: Be sure to postion belt so part number is easily

read.

Center

Distance

Clutch Center Distance -

10″ +.1 / -.05 (254 +2.5 / -1.3mm)

Belt Nominal Length - 40.875″± 3/16

(103.8 cm ± .48 cm)

Loading...

Loading...