CLUTCH

6.19

DRIVE BELT REMOVAL/INSPECTION

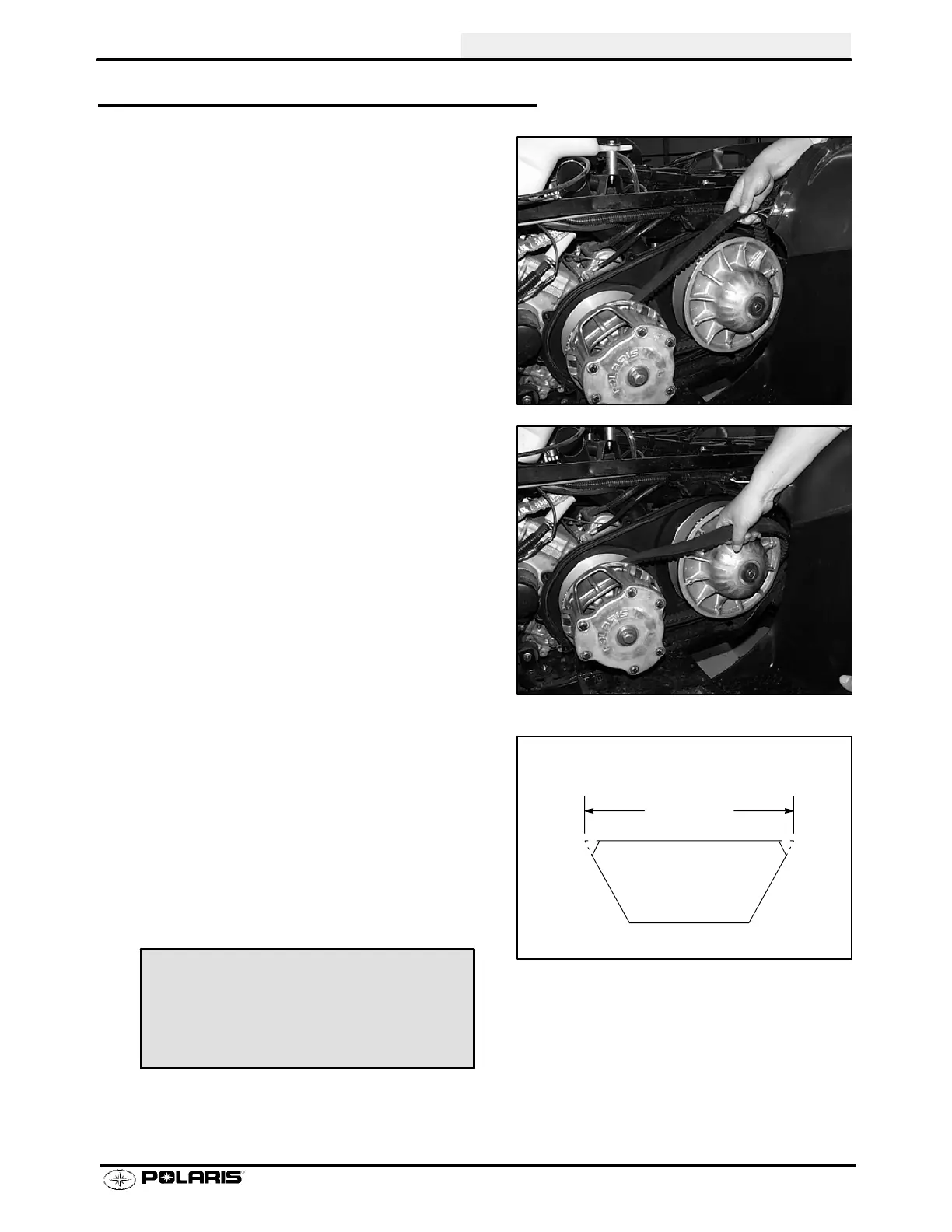

1. Remove outer PVT cover as described in PVT

Disassembly.

2. Mark drive belt direction of rotation so that it canbe

installed in the same direction. NOTE: Normally

positioned so part numbers are easily read.

3. To remove drive belt, apply brake, pull upward and

rearward on belt to open driven clutch sheaves, pull

out and down on belt to slip over the driven clutch

outer sheave.

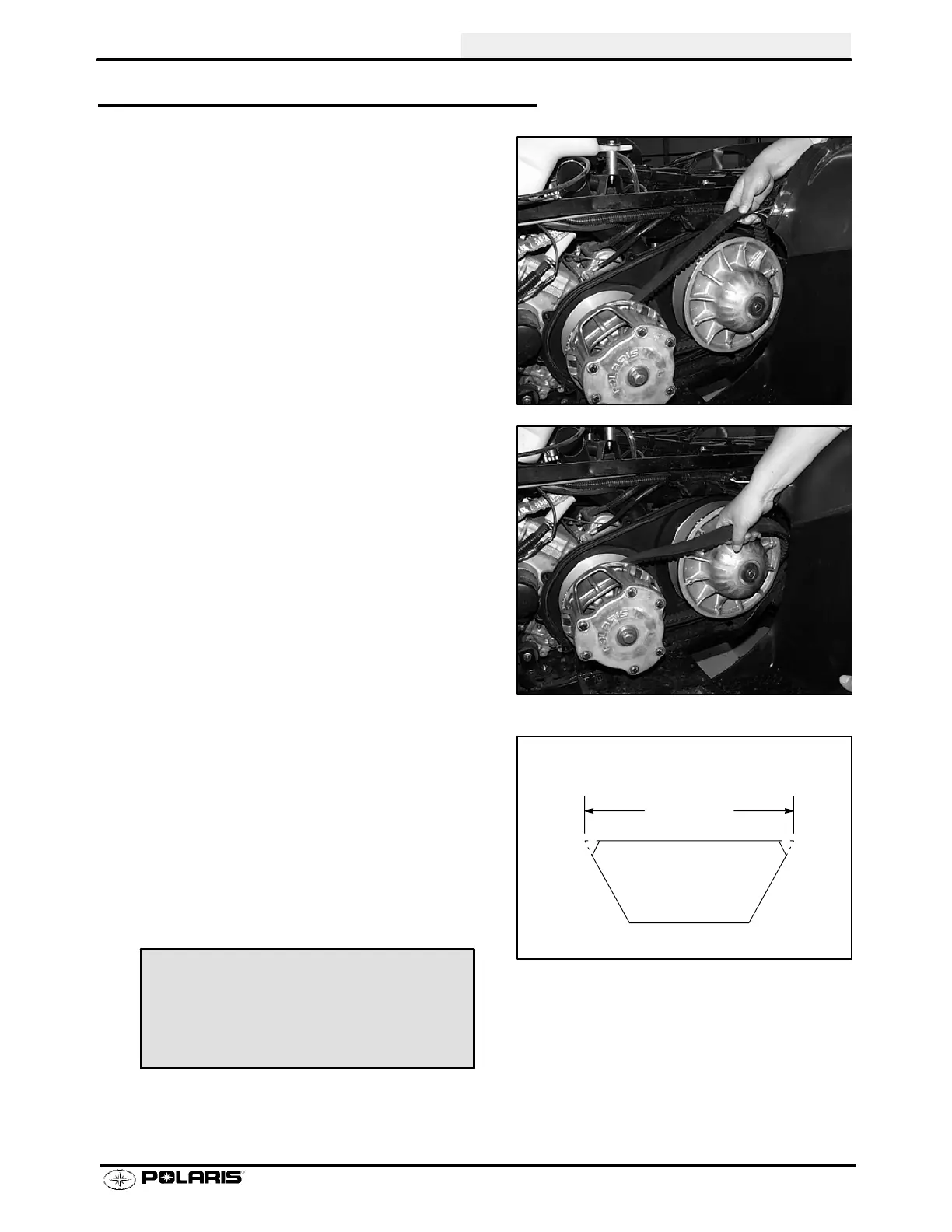

4. Measure belt width and replace if worn severely.

Generally, beltshouldbereplacedifclutchescanno

longer be adjusted to provide proper belt deflection.

S The top edges have been trimmed on some

drive belts. It will be necessary to project the

sideprofilesandmeasure fromcornertocorner.

S Place a straight edge on each side of the drive

belt.

S Place another straight edge on top of belt.

S Measure the distance where the side straight

edges intersect the top, as shownintheillustra-

tion at right.

5. Inspect belt for loose cords, missing cogs, cracks,

abrasions,thinspots,orexcessive wear. Replaceif

necessary.

6. Inspect beltforhourglassing(extremecircularwear

in at least one spot and on both sides of the belt).

Hour glassing occurs when the drive train does not

move and the drive clutch engages the belt.

Projected Belt

Width

Belt Width:

New 1.174 - 1.188″

(2.98-3.02 cm)

Wear Limit 1.125″ (2.86 cm)

Loading...

Loading...