MAINTENANCE

2.11

TRANSMISSION GEARSHIFT LINKAGE ADJUSTMENT, PRE-

LIMINARY

INSPECTION

S If shifting problems are encountered, the transmis-

sion linkage can be adjusted.

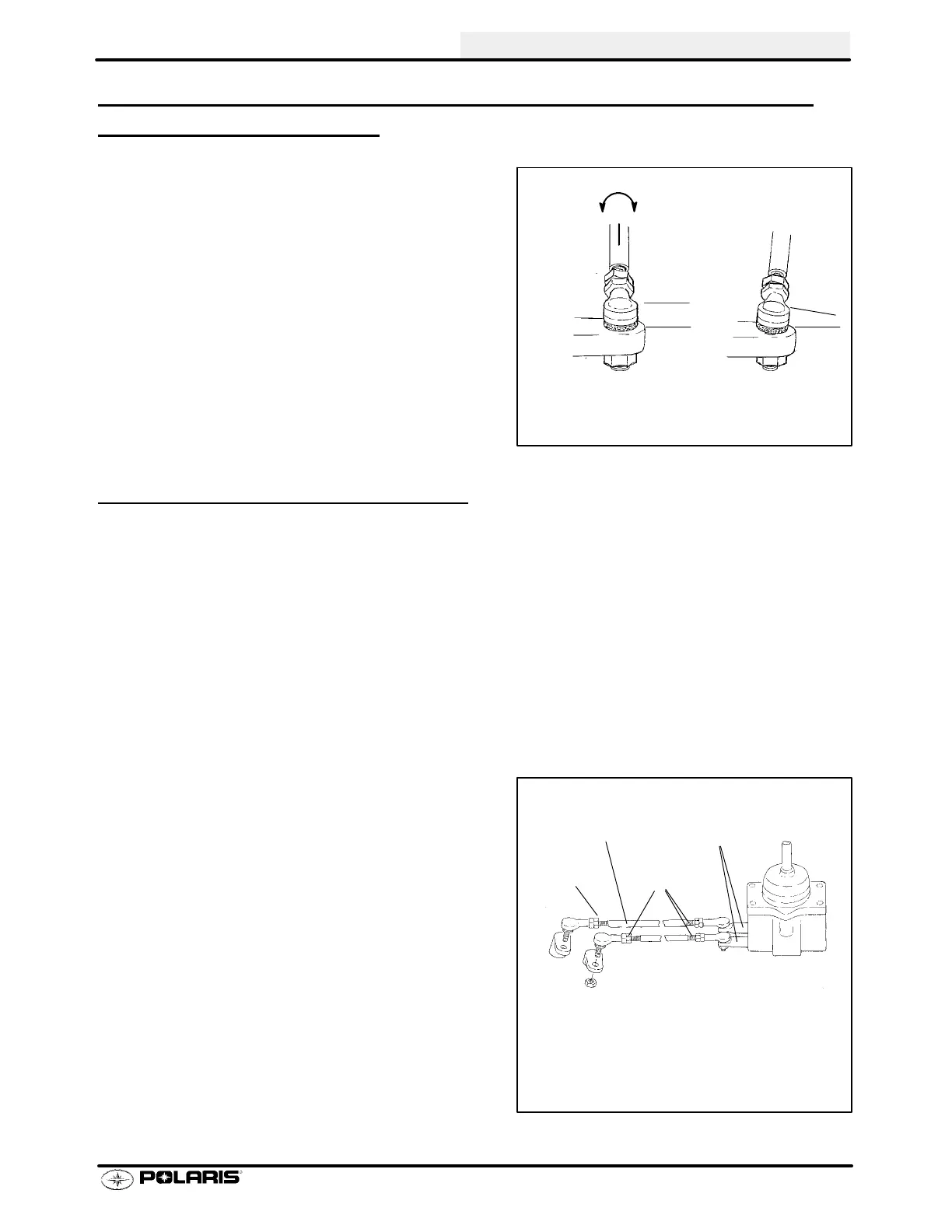

S Tighten shift linkage rod end jam nuts properly after

adjustment. Youshould be able to rotate the linkage

rod between 1/8 and 1/4 turn after both jam nuts are

tight.

S The transmission shift linkage should be periodically

inspected for wear andparts replaced as required to

remove excess play from shift linkage.

S Refer to T ransmission chapter for more information.

SHIFT LINKAGE ADJUSTMENT

Linkage rod adjustment is necessary when symptoms include:

S No All Wheel Drive light

S Noise on deceleration

S Inability to engage a gear

S Excessive gear clash (noise)

S Shift selectors moving out of desired range

NOTE: When adjusting linkage, always adjust both linkage rods. The adjustment of one rod can prevent proper

adjustment oftheotherrod. Remove necessarycomponentstogainaccesstoshiftlinkagerodends(i.e.exhaust

heat shield, exhaust pipe, etc.).

1. Inspect shift linkage tie rod ends, clevis pins, and

pivot bushings and replace if worn or damaged.

Lubricate the tie rod ends with a light aerosol

lubricant or grease.

2. Loosen all rod end adjuster jam nuts see Ill. 1.

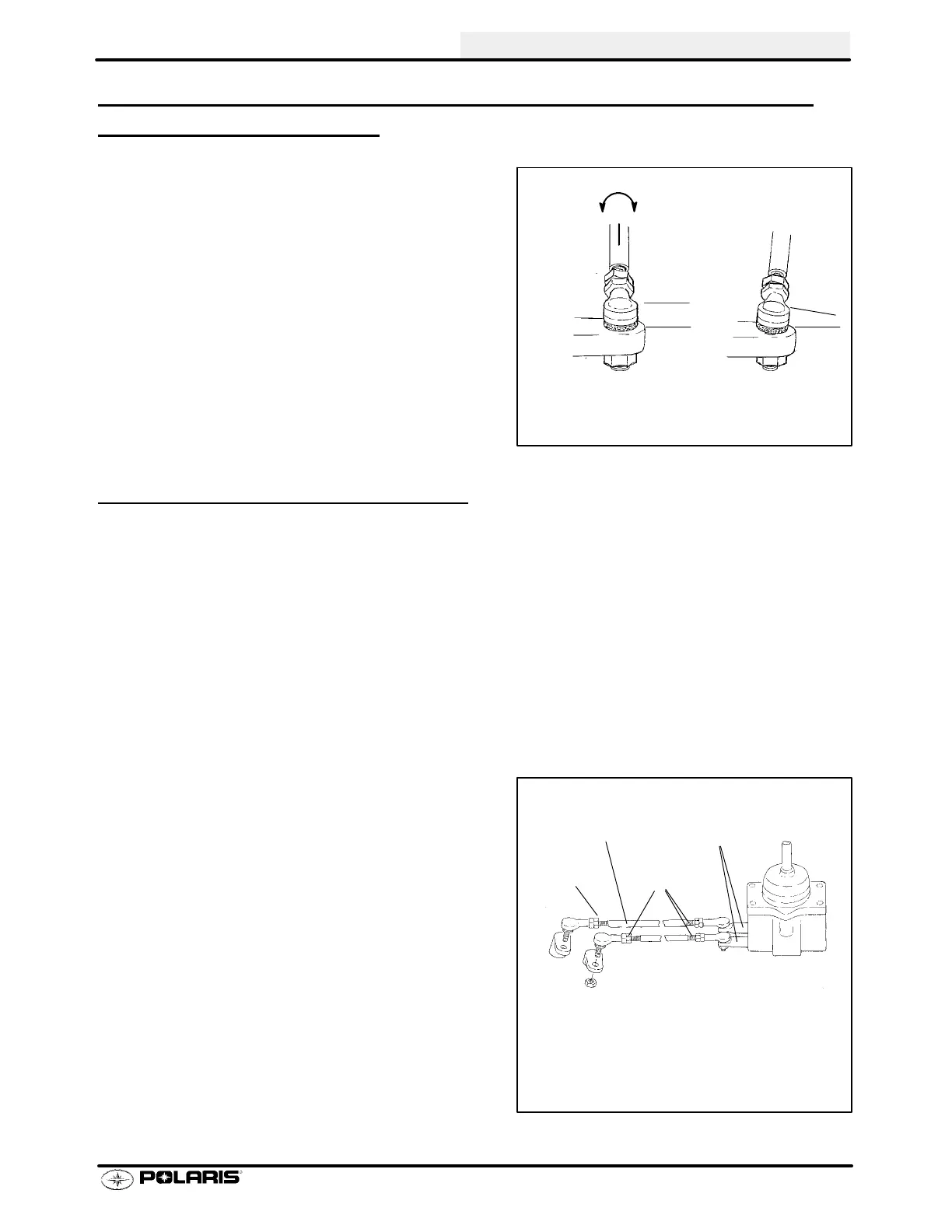

3. Note orientation of tie rod end studs with stud up or

down. Remove both rod end studs from

transmission bell cranks.

4. Be sure idle speed is adjusted properly.

NOTE: It is important to disconnect both rod ends from

the transmission bell cranks. If one linkage rod is incor-

rectly adjusted, it can affect the adjustment of the other

rod.

Correctly Tightened

Jam Nut

Incorrectly Tightened

Jam Nut

Parallel

Linkage rod will rotate

1/8 -1/4 turn if rod ends

are tightened properly.

Low Range

Gear Selector

Slides

Jam Nut

Jam

Nut

NOTE: Rod end orientation, rod ends are

both down.

Ill. 1

Loading...

Loading...