ENGINE

3.53

CRANKSHAFT REMOVAL/INSPECTION

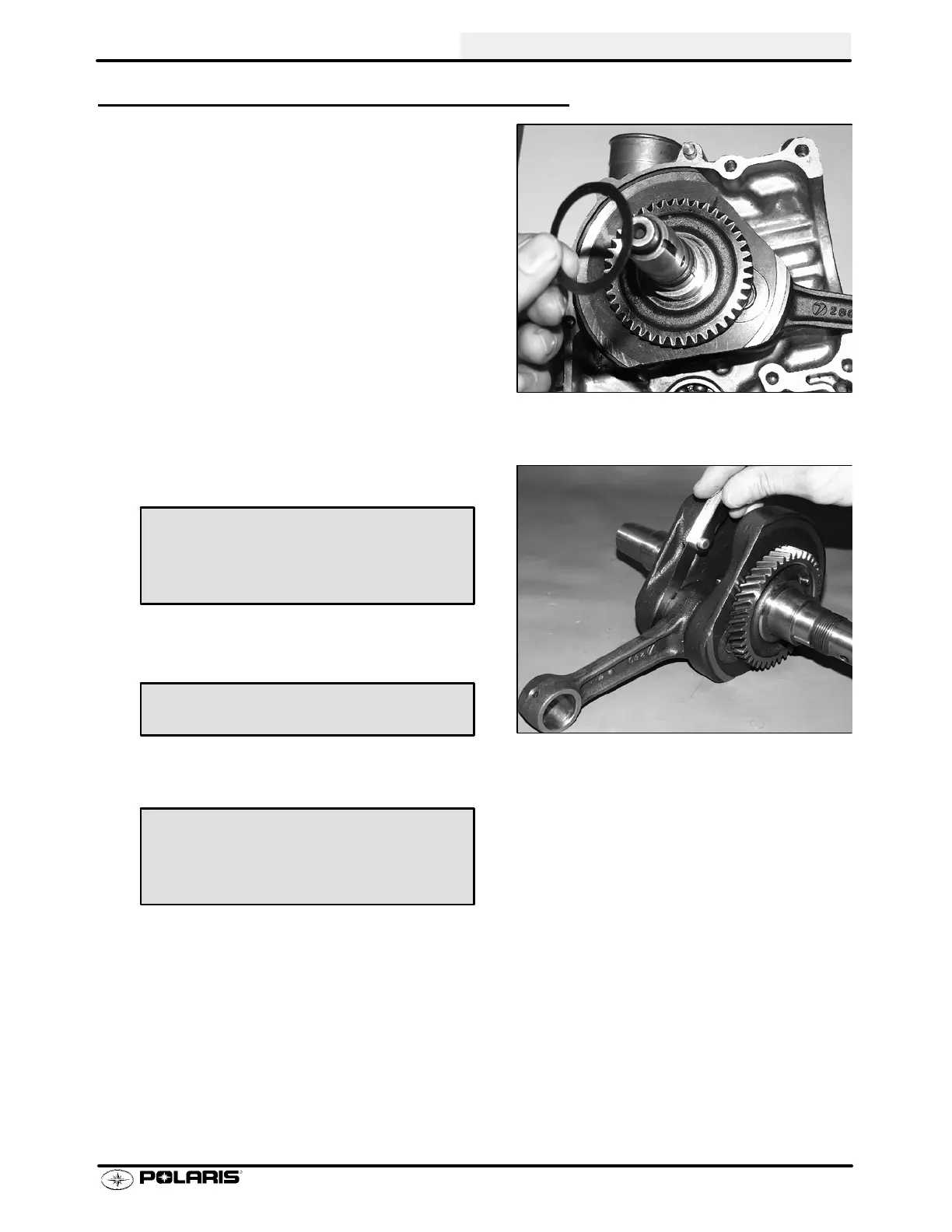

1. Remove the shim washer from the crankshaft.

2. Support the PTO side crankcase and crankshaft;

press the crankshaft out. Be careful not to damage

the crankcase mating surface or connecting rod.

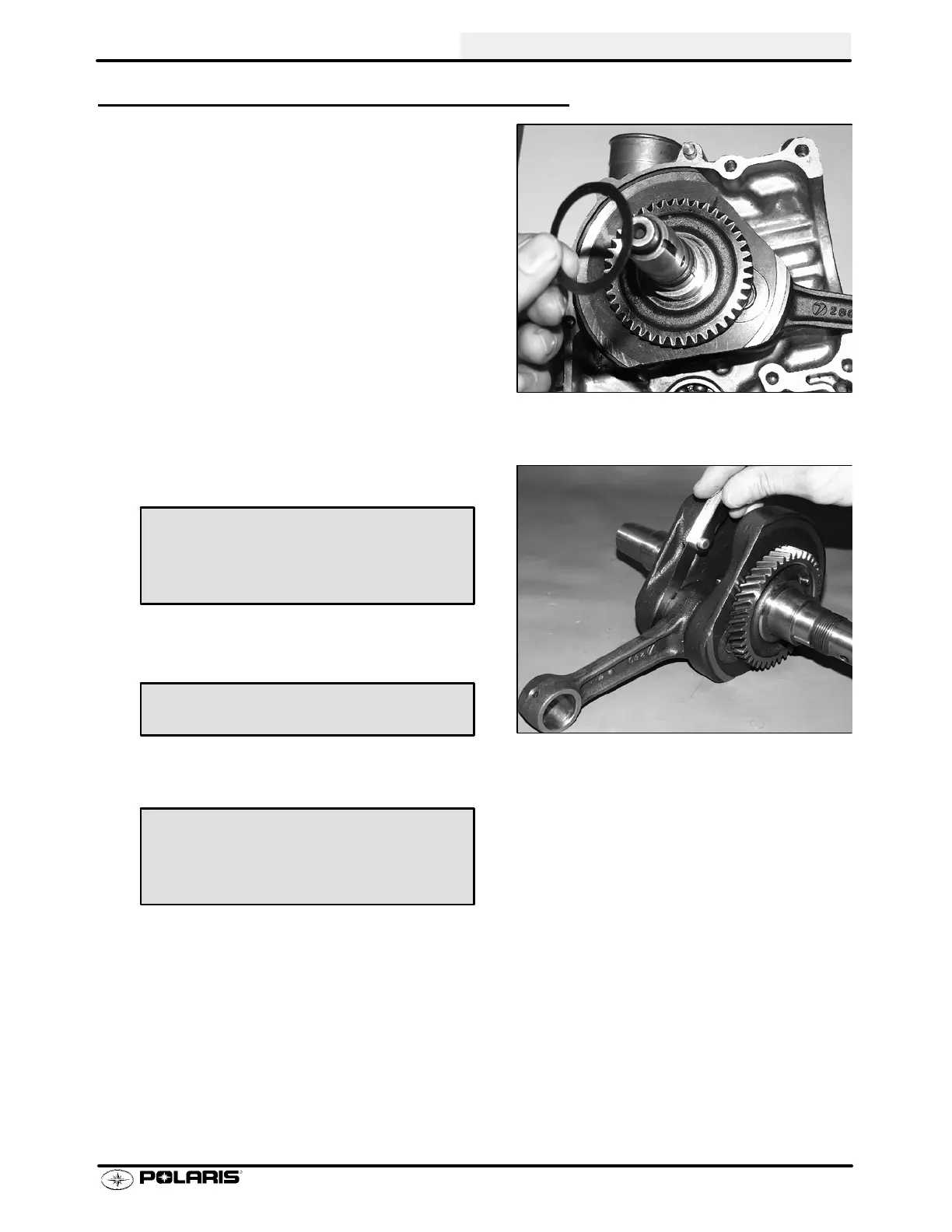

3. Useafeeler gaugetomeasuretheconnectingrodbig

end side clearance.

4. Place the crankshaft in a truing stand or V-blocks and

measure the runout on both ends with a dial indicator.

5. Measure the connecting rod big end radial clearance.

6. Inspect the crankshaft main bearing journals for

scoring and abnormal wear .

Connecting Rod Big End Side Clearance:

Std: .0039-.0256I (.1-.65 mm)

Limit: .0315I (.80 mm)

Max Runout: .0024″ (.06 mm)

Big End Radial Clearance:

Std: .0004-.0015I (.011-.038 mm)

Limit: .0020I (.05 mm)

Loading...

Loading...