MAINTENANCE

2.22

COOLANT LEVEL INSPECTION

Therec over ybot t le,loc at edont heleftsideofthemachine,

mustbemaint ainedbet weent heminim umandmax imum

levels indicated on t he recov ery bot t le.

Withtheengineatoperatingtemperature, the coolant level

should be bet ween the upper and lower mar ks on the

coolant reser voir. If not :

1. Remove reservoir cap. Inner splash cap vent hole

must be clear and open.

2. Fill reservoir to upper mark with Polaris Premium

60/40 Anti Freeze / Coolant or 50/50 or 60/40 mixture

of antifreeze and distilled water as required for freeze

protection in your area.

3. Reinstall cap.

NOTE: If overheating is evident, allow system to cool

completely and check coolant level in the radiator and in-

spect for signs of trapped air in system.

RADIATOR COOLANT LEVEL INSPECTION

NOTE: This procedure is only required if the cooling sys-

tem has been drained for maintenance and/or repair.

However , if the recovery bottle has run dry, or if overheat-

ing is evident, the level in the radiator should be inspected

and coolant added if necessary.

W ARNING Never remove the pressure cap when

the engine is warm or hot. Escaping steam can cause se-

vere burns. The enginemust be coolbefore removingthe

pressure cap.

NOTE: Useof a non-standard pressure cap will not allow

the recovery system to function properly.

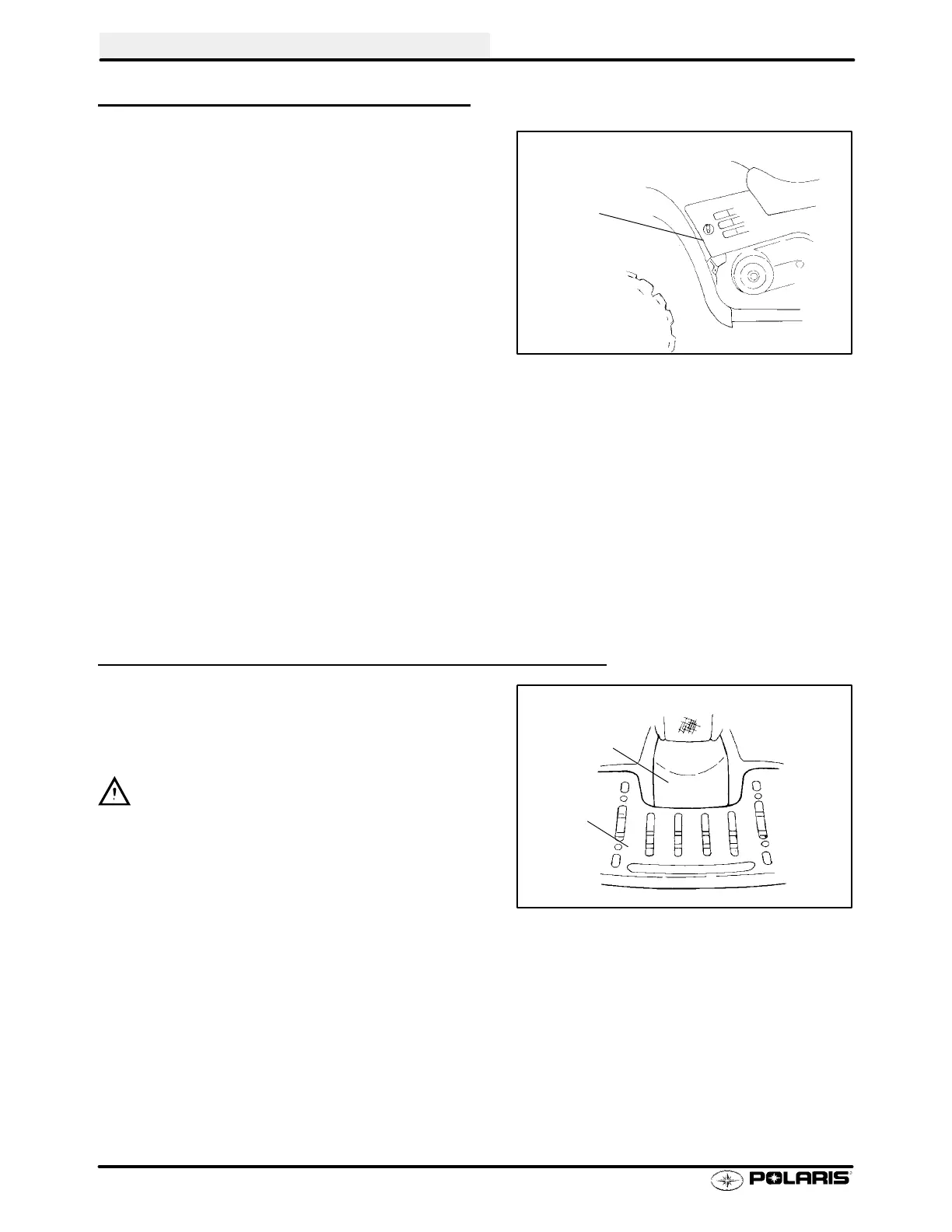

To access the radiator pressure cap:

Remove the four screws securing front rack. Turnhandle

bars full left or right to provide more clearance. Remove

front cover by placing your fingers under the front of the

cover and pulling upward.

Recovery

Bottle

Accessible

Under Side

Panel

Rack

Front

Cover

Loading...

Loading...