CLUTCH

6.18

DRIVE CLUTCH ASSEMBLY, CONT.

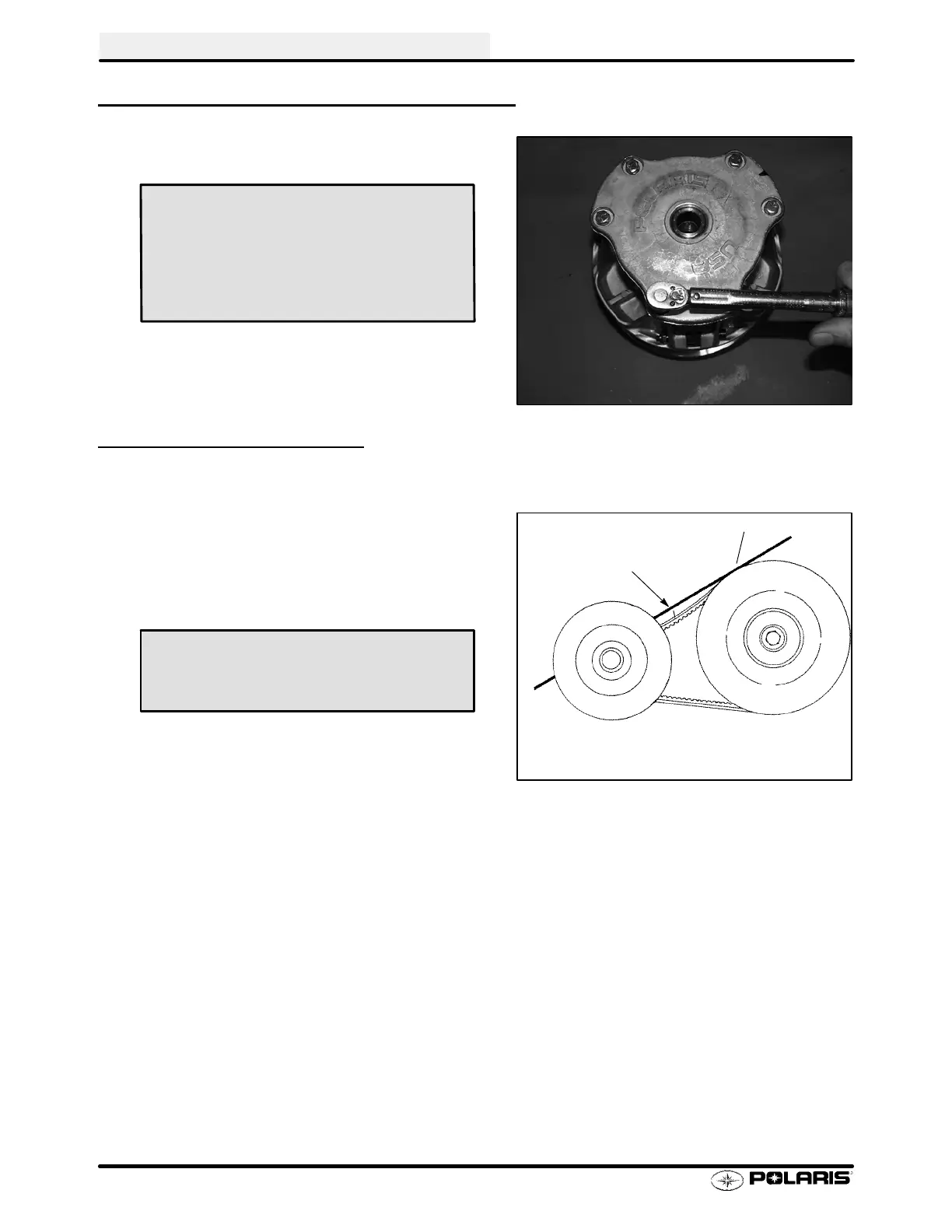

8. Reinstallcover ,aligning“X”markwithothermarks.

Torque cover bolts evenly to specification.

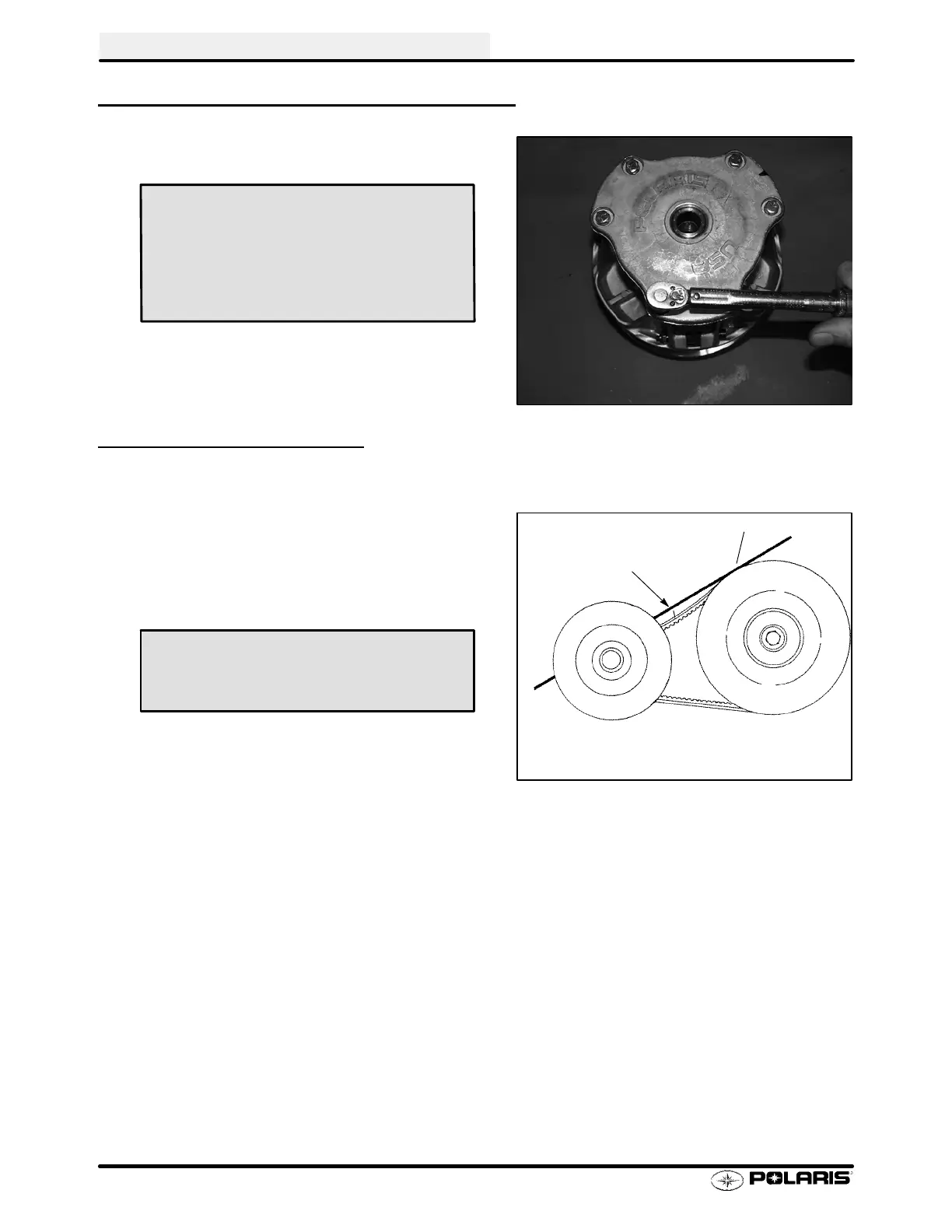

DRIVE BELT TENSION

NOTE: Pinchthesheaveslightlytogetherwithclamptopreventthebeltfrombeingpushedintothedrivensheave.

1. Placeastraightedgeontopofthebeltbetweendriveand

driven clutch.

2. Push down on drive belt until it is lightly tensioned.

3. Measure belt deflection as shown in photo.

If belt deflection is out of specification, adjust by removing or

adding shims between the driven clutch sheaves.

S Remove shims to decrease belt deflection

S Add shims to increase belt deflection

See Driven Clutch Disassembly/Inspection, pages 6.26 -

6.28.

NOTE: Atleastoneshimmustremainbetweentheinnerand

outer sheave of the driven clutch. If proper belt deflection

cannot be obtained, measure drive belt width, length, and

centerdistanceofdriveanddrivenclutch,outlinedinthissec-

tion; all have an effect on belt deflection.

Spider Torque:

200 ft. lbs. (276 Nm)

Cover Screw Torque:

90 in. lbs. (10.4 Nm)

11/8″ (28.5 mm)

Straight Edge

Belt Deflection (Tension):

11/8″ (2.9 cm) - 1 1/4″ (3.2 cm)

Loading...

Loading...