CLUTCH

6.34

EBSTHEORYOFOPERATION

The Engine BrakingSystem (EBS) combines the standard “no-shift” featureofthePolaris VariableTransmission

(PVT) system with the added benefit of engine braking. Outwardly, both drive and driven clutch resemble those

used in a standard PVT system, however, there are some important differences in the EBS clutches:

S

Belt Deflection - It’s important to note that the belt is always “tight” in an EBS system. Belt deflection is not

adjustable. Consequently, there are no shims in the driven clutch for changing drive belt deflection.

S

Special Drive Belt - The bottom side of the belt is grooved for better contact with the one-way clutch (A).

S

One-Way Clutch - One-way clutch (A) located on the drive clutch shaft is the key to system operation.

In a standard PVT system, engine braking occurs briefly on deceleration until engine RPM falls below belt

engagement speed and the drive clutch returns to the neutral position (sheaves open). At this point the drive

belt is no longer engaged with the drive clutch, and no further engine braking occurs.

Drive clutch operation is the same onamachineequipped withEBS at enginespeedsabovebeltengagement.

However ,thedifferencewithEBSisevidentwhenengineRPM isbelowengagementspeedandthedriveclutch

sheaves are open in the neutral position. In a standard PVT system, the belt is loose on the drive clutch shaft

when the clutch is disengaged due to the nominal belt deflection of 1 1/4″ (loose belt). I f the vehic le is mov ing

downhillorc oast ing,thebeltsimplyfr eewheelsonthedriv eclut chshaf tandenginebrakingdoesnotoccur.

WithEBS,t hebeltistightandengagedwit ht heone-wayclut c h.I fthev ehicleism ovingdownhillorcoasting,

the drive t r ain turns the driven c lut ch, belt , and one way c lut ch in t he direc t ion of engine rot at ion. When

theone-way clut chrotat ional speed exceeds dr iveclutc h rot at ionalspeed, t heone-way clutc hlocks t othe

driveclut c hshaf t ,andenginebr akingoc cur s. Ess ent ially,thedr ivenclut c hhasbec omet he“dr iving”clut ch.

Engine braking will continue until drive clutch speed exceeds one-way clutch speed, or until the throttle is

applied and engine RPM reaches clutch engagement speed, lifting the belt off the one-way clutch.

When the engine is idling and the vehicle is at rest, the one-way clutch simply “freewheels” on the drive clutch

shaft.

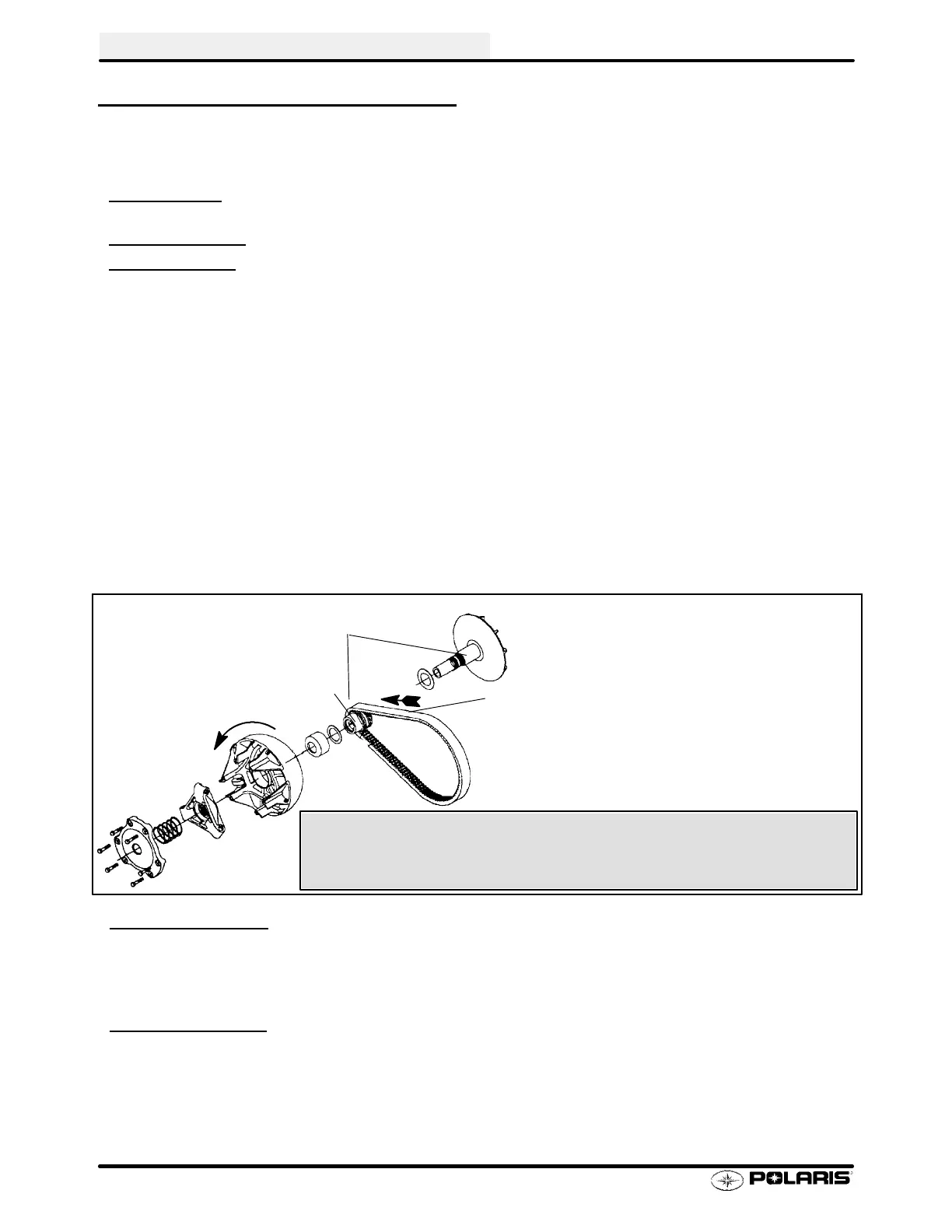

When the forwar d rotat ional speed of the one- way

clut ch (A) exceeds t he speed of t he engine ( and

drive clutc h), t he one-way clutc h locks to the drive

clutc h shaft , and engine br aking occur s.

Drive Clutch Rotation

One-way clutch locks to shaft

in forward direction only.

A

To check the one-way clutch (A), turn the key and engine stop switch to “OFF”

position. Remove the belt and try to rotate the one-way clutch onthe driveclutch

shaft. It should lock to the shaft when rotated counter-clockwise(as viewedfrom

left side of machine), and turn freely when turned in the opposite direction.

S Driven Clutch Spring - Unlike a standard PVT driven clutch spring, the EBS driven clutch spring has no

torsional wind. It is a compression spring only. Like the EBS drive clutch, the driven clutch also utilizes a

one-way clutch, which locks to the shaft during engine braking. To check it, remove the belt and try to rotate

the stationary sheave counterclockwise (as viewed from the left side of the machine). The sheave should lock

to the shaft when rotated counterclockwise, and turn freely when rotated clockwise.

S

High Elevation Setup - As with a standard PVT system, calibration changes are required for optimum

performance at elevations above 3000 feet (900 meters).

Loading...

Loading...