WORKSHOP MANUAL

EDITION

PAGE

119 /

124

Worn armature / brake poles • End of the clutch life • Replace the clutch

Contaminated friction surfaces • Oil seeping on the brake

• Check and repair leaks

• Replace the clutch

Low supply voltage (less than 12 VDC

to the clutch)

• Faulty battery • Replace the battery

• Faulty charging system • Repair or replace.

• Faulty wiring or connections of the

PTO switch

• Check, repair or replace

Inadequate power supply

• Clutch cables broken • Repair or replace.

• Faulty electrical system

• Measure the clutch coil resist-

ance and the voltage supply. If

both are correct, the electrical

system is defective. Repair or

replace.

Overloaded clutch

• Clogged cutting deck • Remove the excess grass

• Deformed shafts. etc. • Replace

Contaminated friction surfaces • Oil seeping on the brake

• Check and repair leaks

• Replace the clutch

The plate hits against the anti-rotational

bracket

• A little bit of noise is normal

• If the noise is excessive, repair

or replace the anti-rotational

device.

Loose clutch on the motor shaft

• Loose assembly (screw not prop-

erly tightened)

• Tighten the mounting screw

according to the specifications

(60-70Nm)

• Fastening screw is too long and

does not allow to axially lock the

clutch

• Use an original replacement

screw

• The mounting washers are too thin

and deformed after tightening the

screw

• Use original spare parts

Broken spring • Loose fitting • Replace the clutch

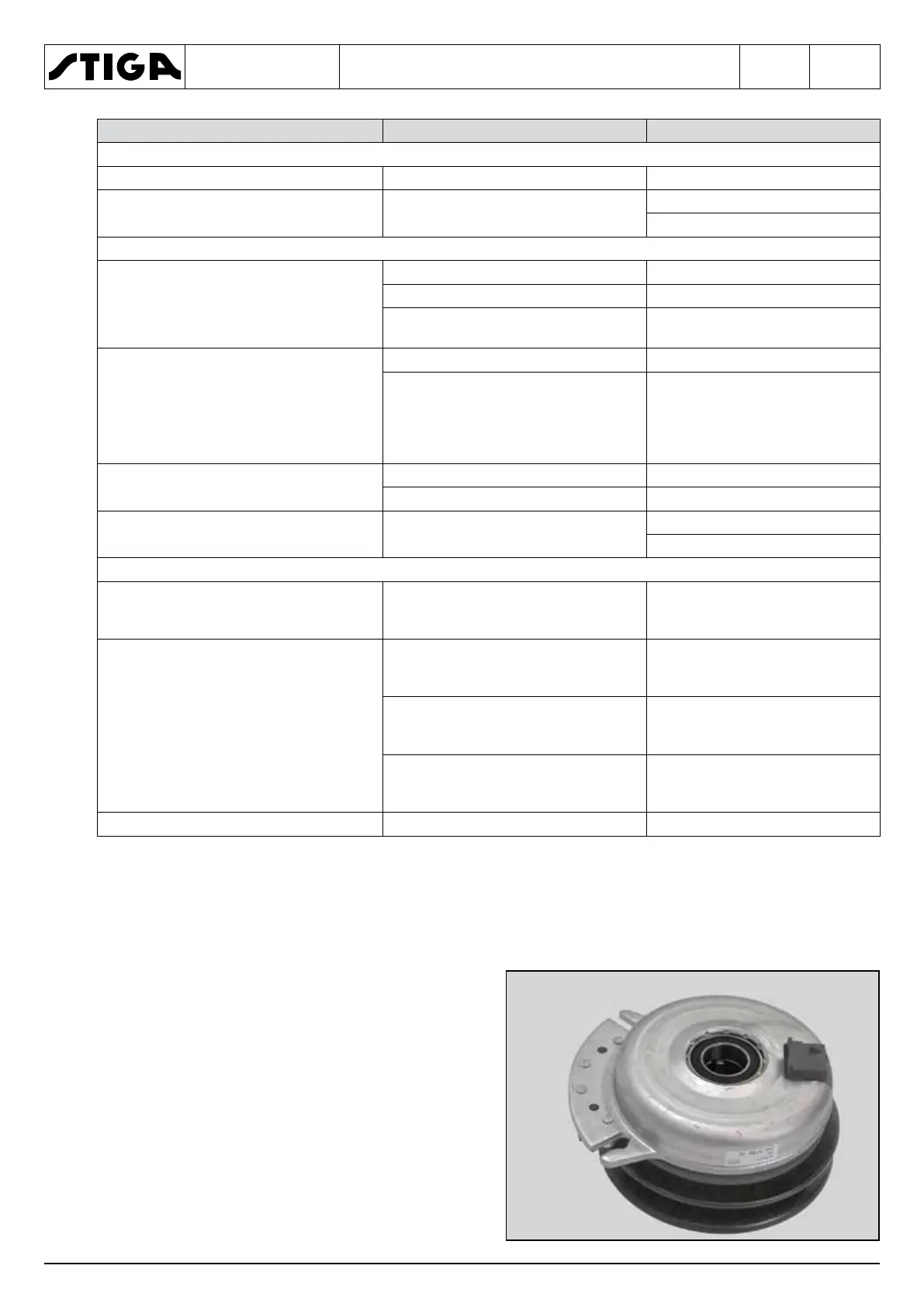

The electromagnetic clutch is used to connect or

disconnect, via a switch, the equipment used on

the machine. In addition, the clutch is designed

to activate a brake on the output shaft, when it is

disengaged.

• The field coil is mounted to a bearing support

and does not rotate.

• The rotor is attached to the power output shaft

and rotates around the field assembly.

• The assembly is connected to the output pulley.

• The armature unit is assembled close to the

brake unit rotor.

Loading...

Loading...