WORKSHOP MANUAL

PARK

Chapter

8 - HYDRAULIC SYSTEM

EDITION

2020

PAGE

98 /

124

8.4.2 Valve disassembly

NOTE The valve must be removed with the by-

pass open.

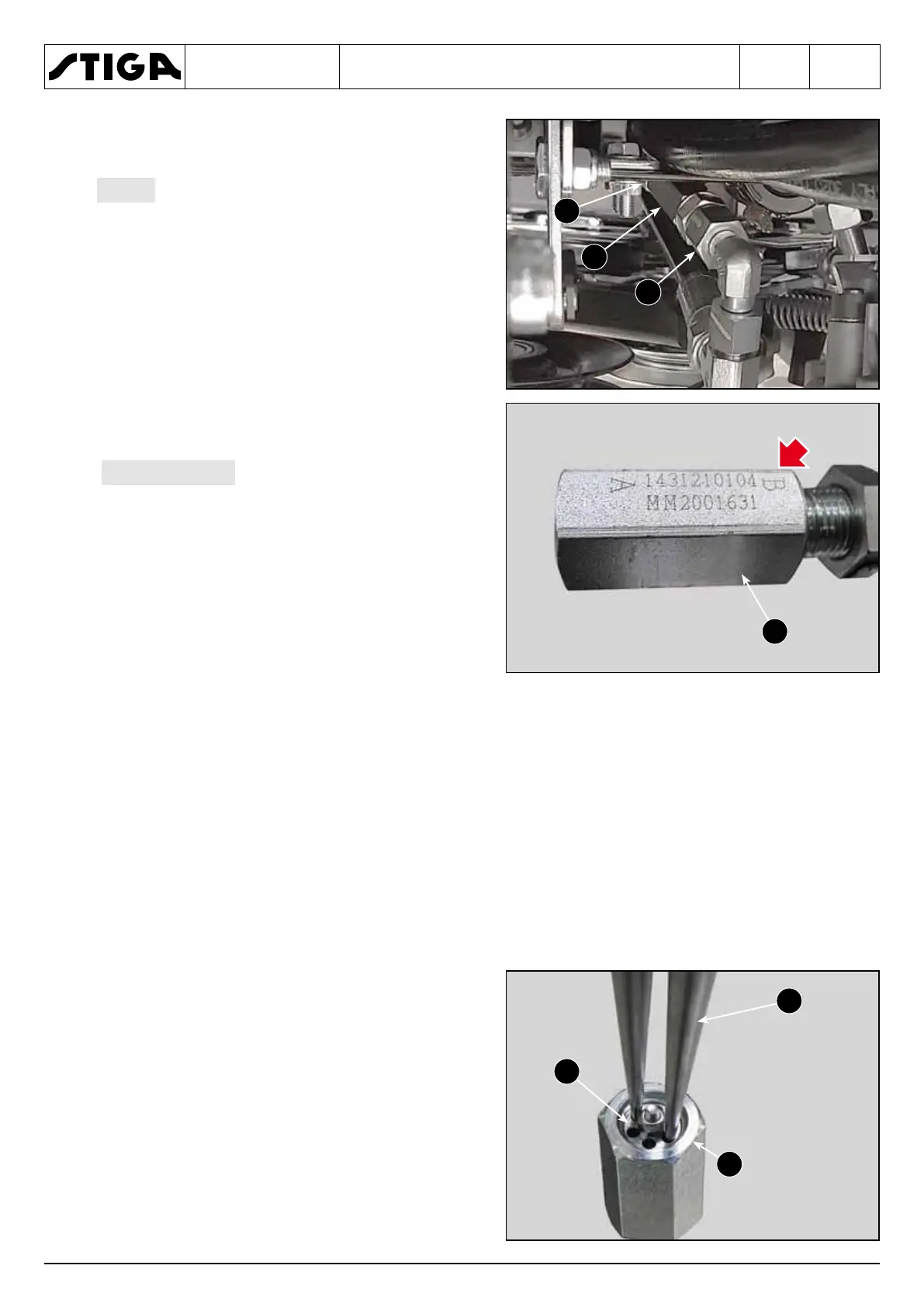

1. Loosen the two nuts (1) of the elbow fitting, ap-

propriately collecting the oil still present in the

pipes.

2. Unscrew the balance valve (2).

IMPORTANT Each balancing valve (2) is

equipped with a code punched on one face of

the hexagon. This code identifies the valve mod-

el, which is different for each type of machine

and is essential for any spare parts request.

8.4.3 Valve calibration

The dynamic balancing valve has a standard setting of 0.15 mm; this value can be adjusted in the

range ± 0.05 mm with respect to the standard calibration.

● With the dynamic balancing valve set at 0.10 mm, the valve closing time is reduced, which

means an increase in the traction performance at the expense of smooth steering.

● With the dynamic balancing valve set at 0.20 mm, the valve closing time increases, which

means an increase in the fluidity of the steering at the expense of traction performance.

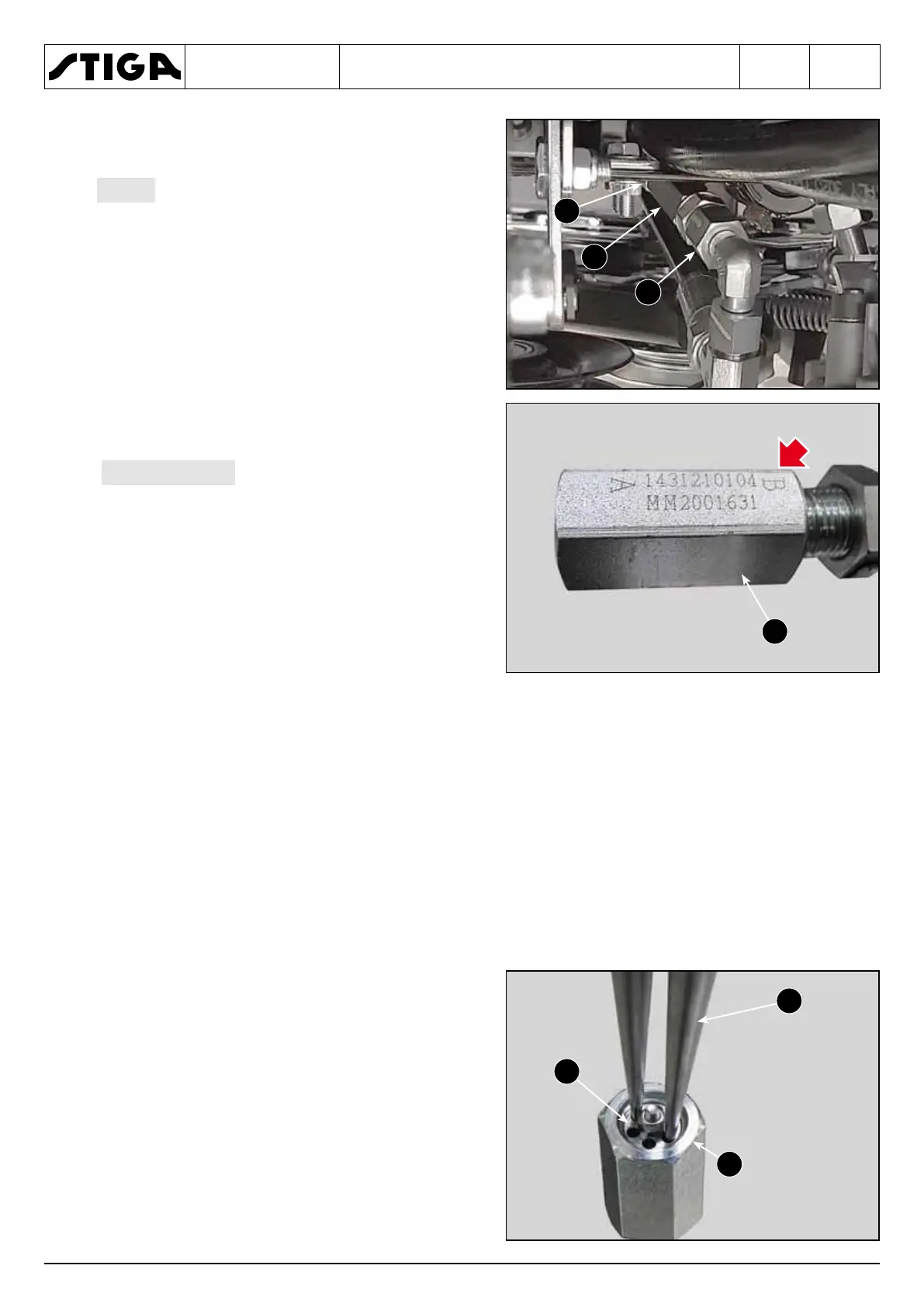

To change the calibration, it is necessary to dis-

assemble the valve and act as follows.

1. Secure the valve body (1) in a vice and un-

screw the internal valve (2) with the help of

long needle nose pliers (3) or a special tool.

3

2

1

2

1

2

1

Loading...

Loading...