WORKSHOP MANUAL

EDITION

PAGE

59 /

124

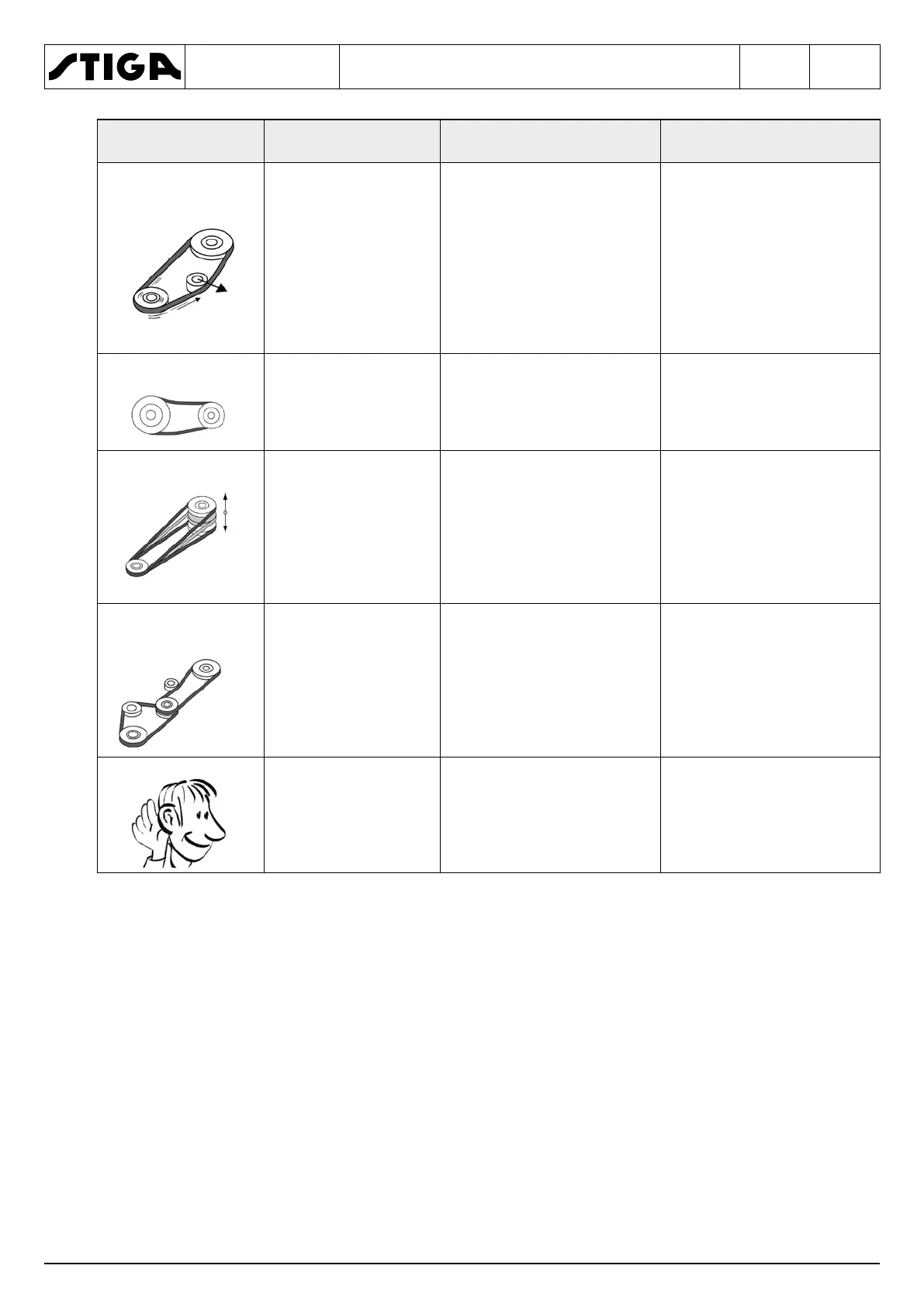

Example

Belts available on the

market

Original spare belts Notes

Acceleration.

Some belts only en-

gage with the pulleys

when the engine is

running at operating

speed and this gener-

ates excessive heat.

The belt follows the speed

of the engine in continuous

acceleration until the maxi-

mum speed is reached.

Standard belts are made

of natural rubber and only

capable of withstanding

temperatures up to 70°C.

Original spare belts are

made of chloroprene rubber

capable of withstanding

temperatures up to 90°C.

Length.

Manufactured in

standard interval

lengths.

Made in a specific length

designed to ensure perfect

adhesion to the pulley.

The distance between the

pulleys is fixed. The belt

tensioner ensures that the

original belt maintains opti-

mal tension.

Floating pulley on

cutting equipment.

Designed to trans-

mit power between

aligned, parallel and

fixed pulleys.

The original Power Take

Off (PTO) belt is designed

to work even if the pulleys

move up and down and tilt

at the same time.

The equipment follows the

ground beneath it and this

means that the pulley is

constantly moving.

To withstand extreme oper-

ating conditions, the origi-

nal belts are made of fibre

reinforced rubber.

Curvature in two

directions.

Designed to curve

around the pulley in

one direction.

Most of the belts installed

on the machines have

tensioning rollers that act

on the outer side of the belt.

This means that while the

belt is being used it must tilt

both inwards and outwards.

All the original belts, which

work with tensioning arms

acting on the external side,

are equipped with reinforce-

ments.

The reinforcement is de-

signed specifically for these

specific cases.

Noise.

Made without special

requirements for this

specific factor.

The original belts are care-

fully selected to limit the

increase in noise produced

by the machine during

operation.

Depending on the function,

one of the following belt

types is suitable:

• Coated

• Anti-friction

• Open sided

It is essential to maintain the transmission belts in perfect working order for the machine to func-

tion properly.

Premature wear, breakage or deterioration of the V-belts can be caused by:

• Improper tension

• Misalignment

• Damaged pulleys

• Overload

The table shows the possible origins of abnormal situations and the corrective actions to be taken.

Loading...

Loading...