WORKSHOP MANUAL

EDITION

PAGE

60 /

124

Problem Probable cause Corrective action

1. Rapid belt wear Friction Check the belt path

Pulleys misalignment Check

Worn or damaged pulley grooves Replace pulleys

Inadequate belt Check the parameters and replace the

belt with the appropriate original spare

part

Belt slippage Check the tensioning system

2. Damaged sides and

twisted belt in the pulley

Damaged internal structure Replace the belt and check for correct

mounting

Overload Check the operating conditions

“Jerky” operating use Check the operating conditions

3. Belt slippage Loosening the belt Check the tensioning system

Overload Check the operating conditions

Worn pulleys, with the belt resting

on the bottom

Replace pulley

Presence of oil Clean up any oil or grease residue

4. Belt screeching Loosening the belt Check the tensioning system

Overload Check the operating conditions

5. Cracked belt Belt slippage Check the tensioning system

Excessive heat Adapt operating conditions

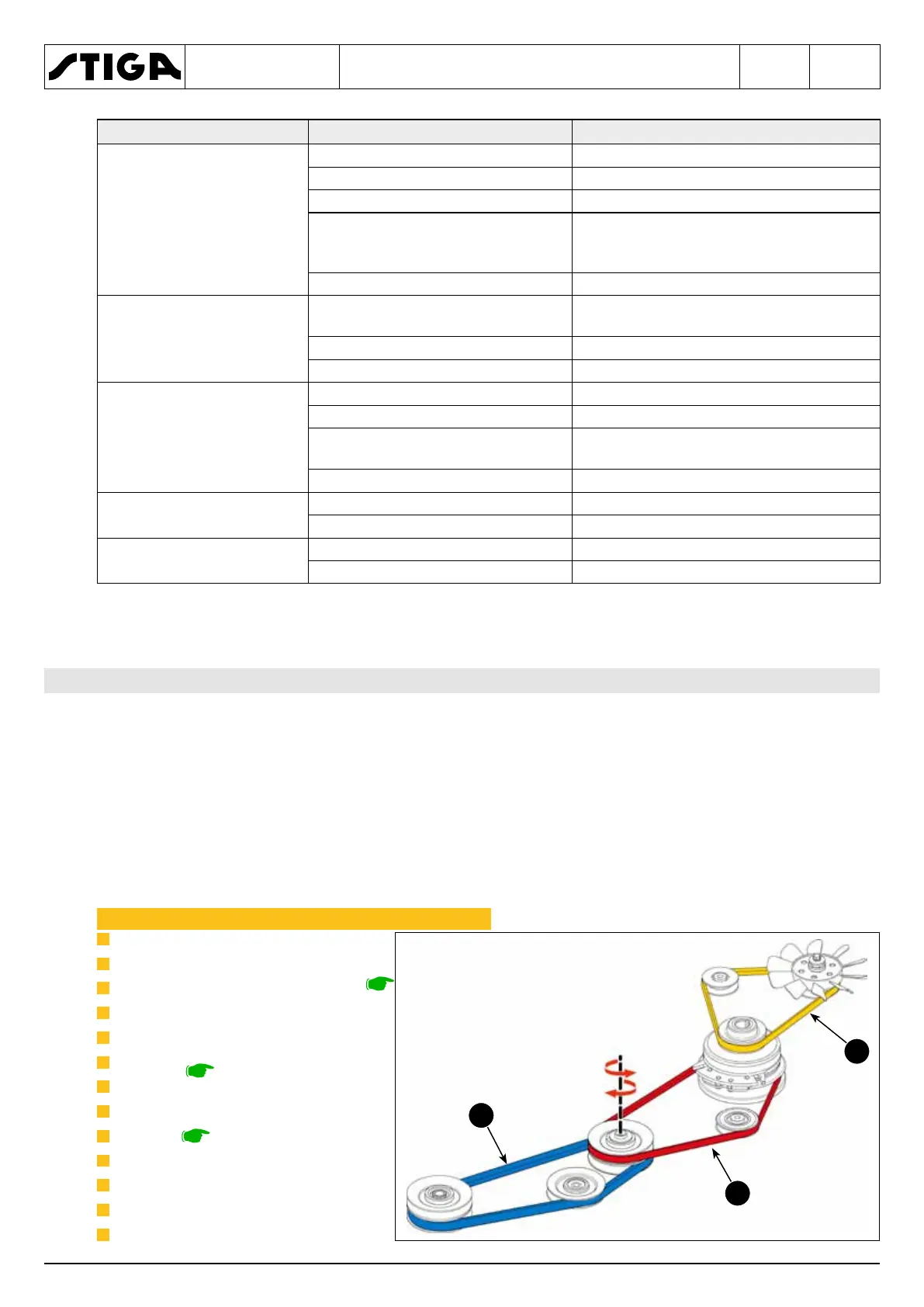

The number and development of the belts present some differences between two drive wheels

(2WD) and four drive wheels (4WD) models; these differences are highlighted in the following

drawings, to which reference should be made to identify the belts described in the individual para-

graphs.

▶▶

Engine / transmission belt

.

Engine / articulated joint axis

belt

.

Articulated joint axis / PTO

belt .

Loading...

Loading...