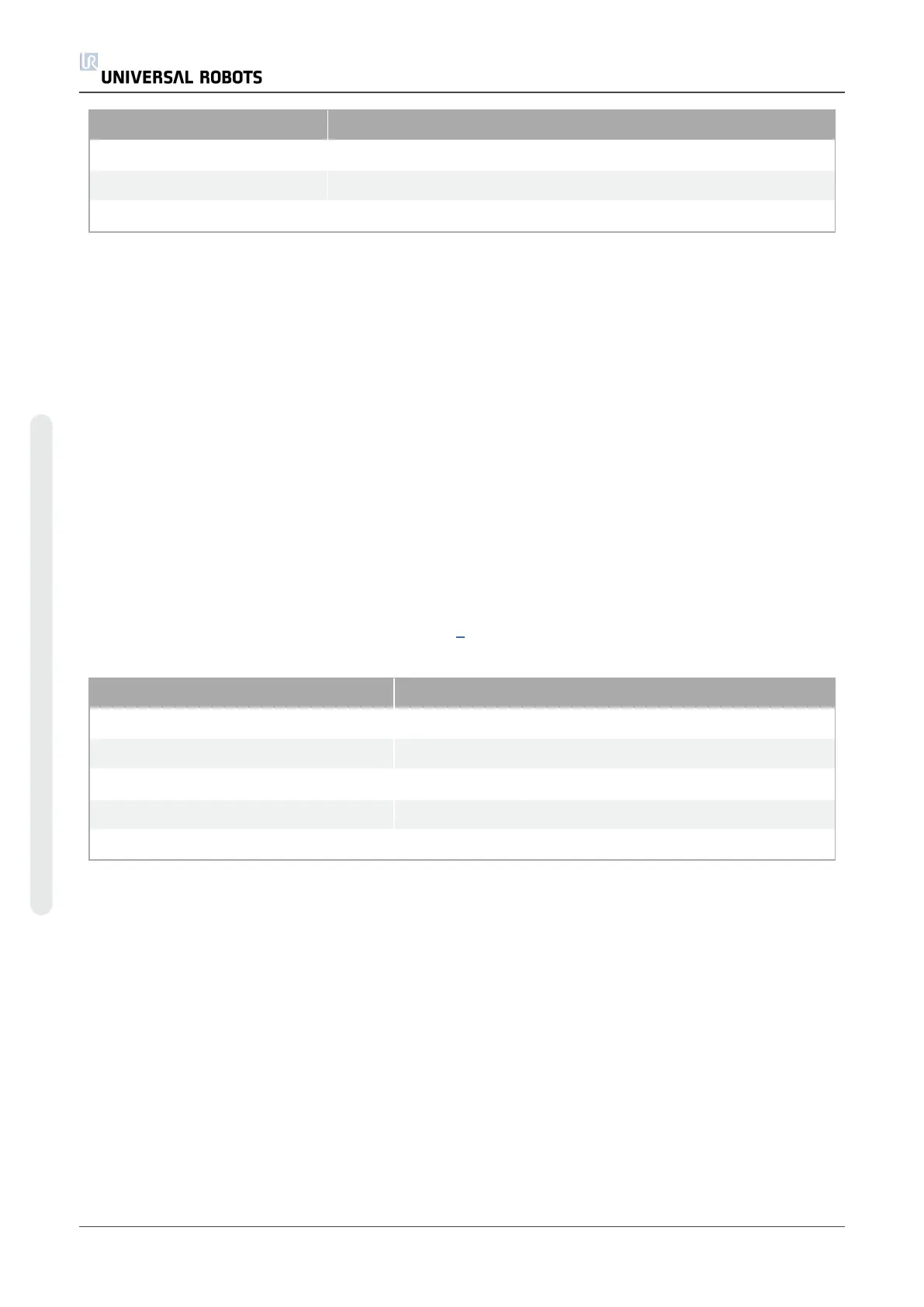

Limiting Safety Function Description

TCP force Max.pushing force of the robot TCP

Momentum Max.momentum of the robot arm

Power Max.applied robot arm power

1.6.2. Stopping times of the Safety System

The stopping time of the safety system is the time from a fault or violation of a safety-related

function occurs to the robot is brought to a complete stop and the mechanical brakes are

engaged.

The maximum stopping times in the table must be considered if the safety of the application

relies upon the stopping time of the robot. E.g. if a fault in the robot results in a stop of a

complete factory line, where certain actions must take place immediately after the stop, the

maximum stopping times must be considered.

The measurements are conducted with the following configuration of the robot:

• Extension: 100% (the robot arm is fully extended horizontally).

• Speed: The TCP speed limit of the safety system is set to the described limit.

• Payload: maximum payload handled by the robot attached to the TCP ( 10 kg).

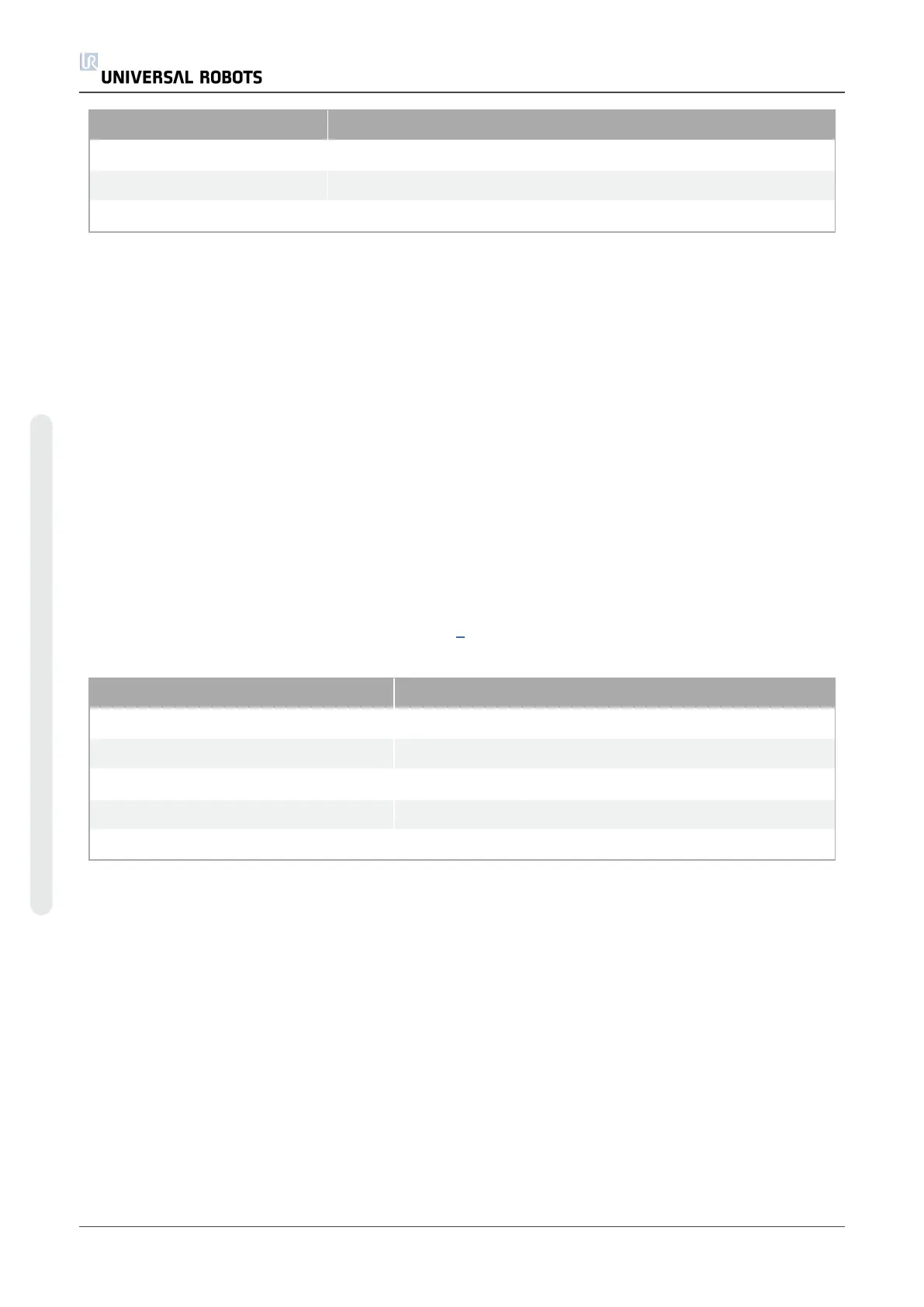

The worst case stopping time for Stop Category

1

0 in case of a violation of the safety limits or

interfaces can be seen in the following table.

TCP Speed Limit Maximum Stopping Time

1.0m/s 450ms

1.5m/s 500ms

2.0m/s 550ms

1.5m/s 600ms

3.0m/s 650ms

1.6.3. Limiting Safety-related Functions

Advanced path control software decreases speed or issues a program execution stop if the robot

arm approaches a safety-related limit. Violations of limits will hence only occur in exceptional

cases. Nevertheless, if a limit is violated, the safety system issues a Stop Category 0.

The system is considered de-energized when the 48V bus voltage reaches an electrical potential

below 7.3V. The de-energizing time is the time from a detection of an event until the system has

been de-energized.

UR10 14 User Manual

Copyright © 2009–2020 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...