Appendix 2 Application

Mode 6: pulse command position mode

Equipment introduction:

This is a welder. Workpiece 1, 2, 3 are the object to be operated. 2 and 3 is fixed on B and A

individually. A and B can whole move and be pushed by ball screw E and F. The screw pitch is 5mm.

C and D is servo motor. G and H is reducer. The deceleration ratio is 40.

It needs to adjust the machine with standard dimension workpiece and find the origin of A and B.

Workpiece 1 lies on the worktable and moves left and right. Its dimension is positive tolerance, cannot

shorter than standard workpiece. The process to put the workpiece is random. It requires that the left

and right soldering is symmetrical.

A and B move toward 1 with 3 and 2 at the same speed. Whatever the position of 1, 2 or 3 will touch 1

at first and push 1 to another side until 2 and 3 all touch 1. The result is the motor torque will increase.

At this time, 1 will at the symmetrical position.

A and B will return to the origin position after soldering is finished.

Analysis

1. Make sure the work mode: 6

2. It needs to judge whether 2 and 3 touch 1 when finding the symmetrical point. The sign is servo

output torque will increase. It needs to use torque limit (P4-02, P4-03) and torque limit output signal

/CLT.

3. As the dimension of workpiece is larger than standard, offset pulse will remain in servo when the

symmetrical point is found. /CLR signal can clear the pulse. The servo motor running distance is

different from PLC pulse number. If it needs to know the actual distance, servo encoder feedback

/AO, /BO and AB phase count are needed.

4. The motion direction of A and B.

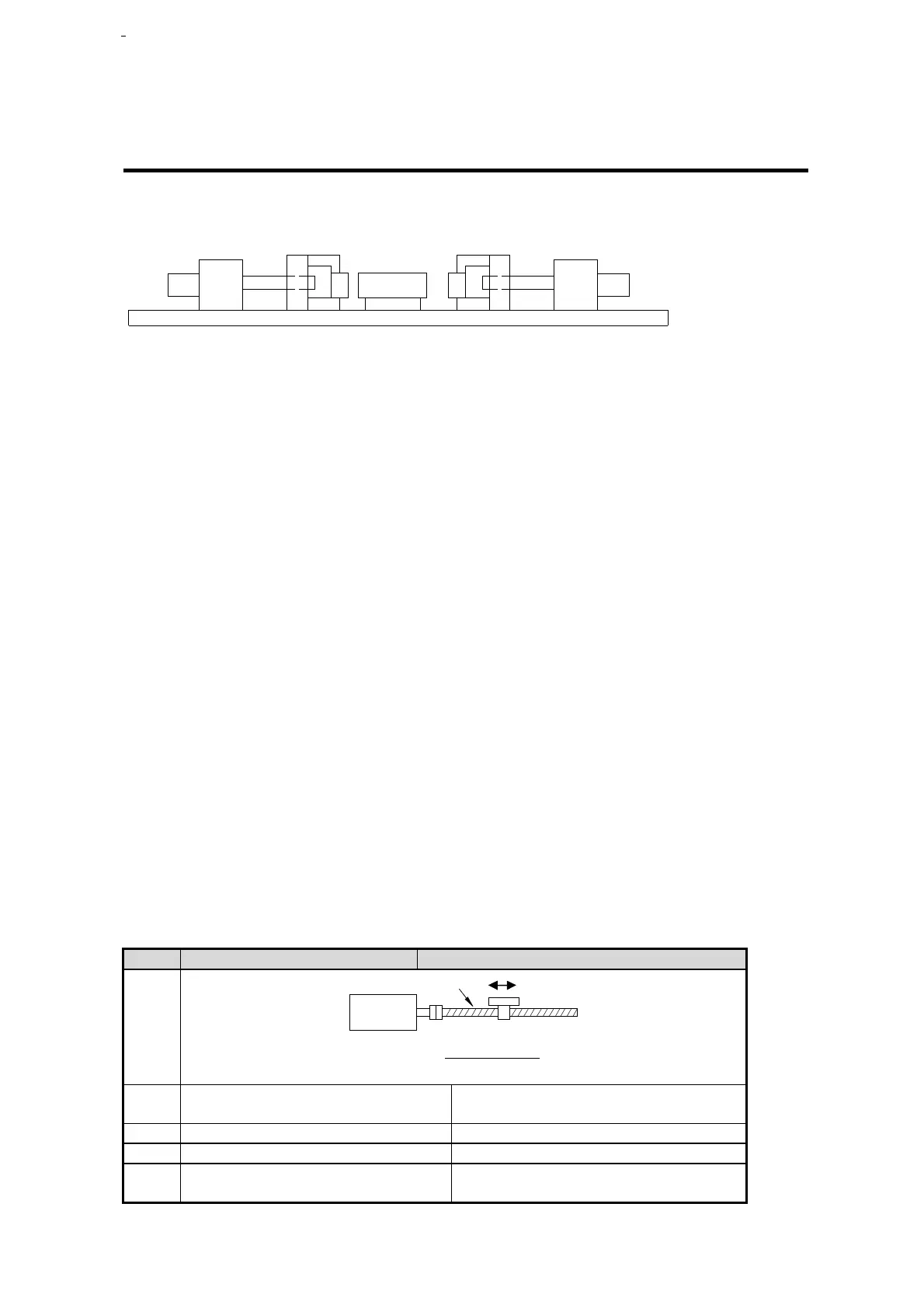

Signal and terminal

/COIN positioning finished signal: SO1

/CLT torque up to upper limit output: SO2

/CLR pulse offset clear input: SI1

Encoder feedback signal /AO, /BO

Calculate the electronic gear ratio

Confirm the mechanical specification

Reduction ratio: 40/1

Confirm the encoder pulse number

Calculate the motion value of load

shaft rotate 1 circle

1 23

A

B

E

F

G

H

D

C

Loading...

Loading...