7 -85

CHASSIS

Pegaso 650 I.E.

7.9.2 CHECKING THE COMPONENTS

aCAUTION

Make sure that all the components are intact, particu-

larly the following.

7.9.3 REAR FORK BEARINGS

Carry out the check with the bearings mounted on the

rear fork.

CHECKING THE ROTATION

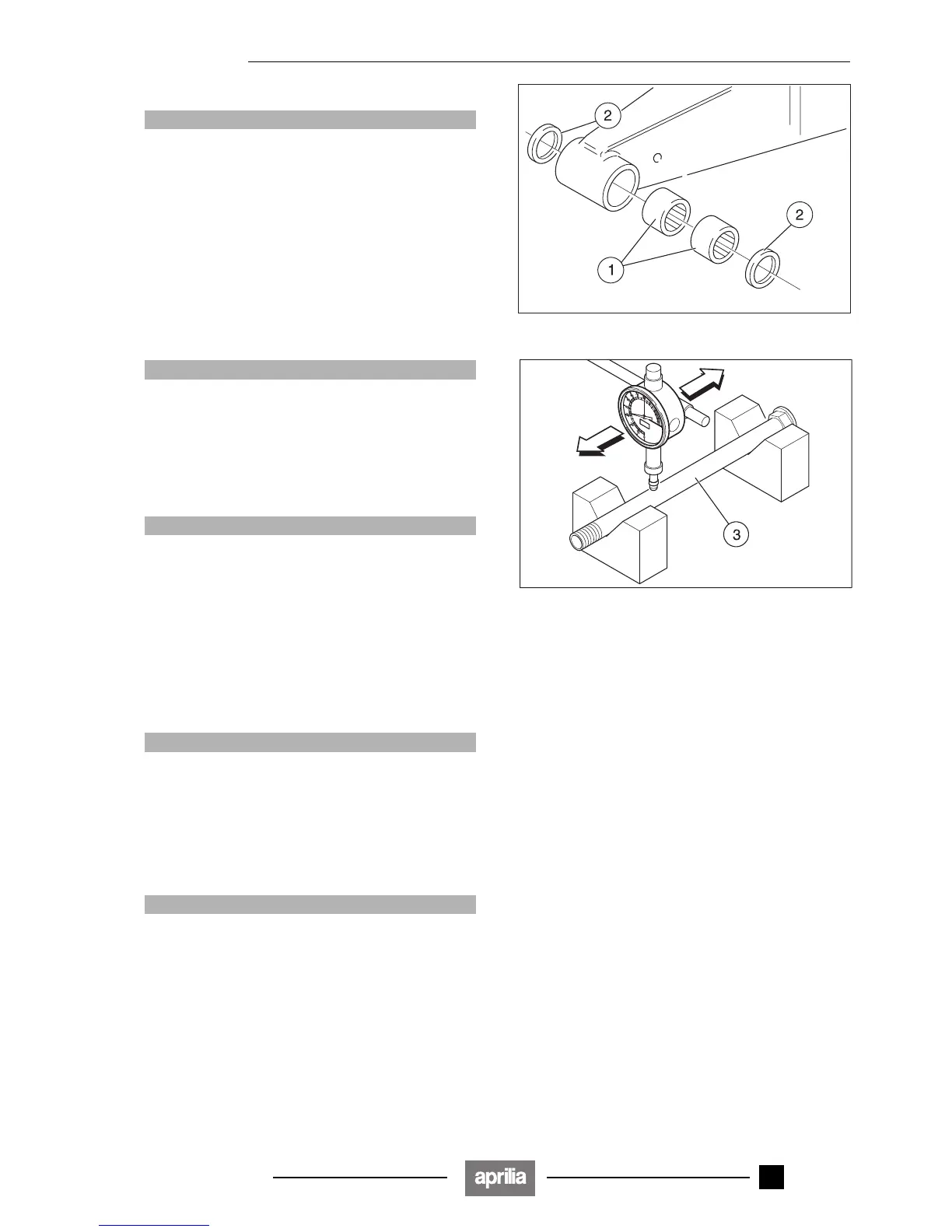

◆ Manually rotate the rollers (1) of each single bearing.

The rotation must be regular, smooth and noiseless.

If one or both bearings is/are not in compliance with the

check parameters:

~ Remove the seal (2).

◆ Wash the bearings with a clean detergent.

aCAUTION

Prevent the compressed air from making the bear-

ings turn, since this would damage them.

◆ Dry the bearings with compressed air.

◆ Repeat the rotation check on both bearings.

If one or both bearings is/are not in compliance with the

check parameters:

◆ Change the rear fork bearings, see 7.9.6 (DISASSEM-

BLING THE REAR FORK GASKETS).

aWARNING

Always change both bearings.

Always replace the bearings with bearings of the

same type.

CHECKING THE END AND RADIAL PLAY

◆ Check the radial play and the end play.

End play: a minimum end play is allowed.

Radial play: none.

If one or both bearings is/are not in compliance with the

check parameters:

◆ Change both rear fork bearings, see 7.9.6 (DISAS-

SEMBLING THE REAR FORK GASKETS).

aWARNING

Always change both bearings.

Always replace the bearings with bearings of the

same type.

7.9.4 REAR FORK GASKETS

◆ Make sure the seals (2) are intact; should they prove

damaged or feature signs of excessive wear, change

them.

aWARNING

Always change both seals.

Always replace the gaskets with gaskets of the same

type.

7.9.5 REAR FORK PIN

◆ Check the eccentricity of the fork pin (3) by means of a

comparator. If the eccentricity exceeds the limit value,

change the fork pin (3).

Maximum eccentricity: 0.3 mm.

Release 00/2002-02

- 00