Maintenance, 10h

4812160001_A.pdf 2014-08-25

Fuel tank - Filling

Fig. Fuel tank

1. Filler pipe

1

Top up the fuel tank every day. Follow the engine

manufacturer's specifications for diesel fuel.

The new Tier 4i/Stage IIIB Cummins engines

require the use of Ultra Low Sulphur Diesel

(ULSD) fuel, which has a sulphur content of 15

ppm (parts per million) or less. A higher sulphur

content will cause operating problems and put the

useful life of components at risk, which can lead

to engine trouble.

The new Tier 4i/Stage IIIB Cummins engines

require the use of Ultra Low Sulphur Diesel

(ULSD) fuel, which has a sulphur content of 15

ppm (parts per million) or less. A higher sulphur

content will cause operating problems and put the

useful life of components at risk, which can lead

to engine trouble.

Stop the engine. Short-circuit (press) the filler gun

against a non-insulated part of the roller before

refuelling, and against the filler pipe (1) while

refuelling.

Stop the engine. Short-circuit (press) the filler gun

against a non-insulated part of the roller before

refuelling, and against the filler pipe (1) while

refuelling.

Never refuel while the engine is running. Do not

smoke and avoid spilling fuel.

Never refuel while the engine is running. Do not

smoke and avoid spilling fuel.

The tank holds 260 liters of fuel.

Hydraulic reservoir - Check fluid level

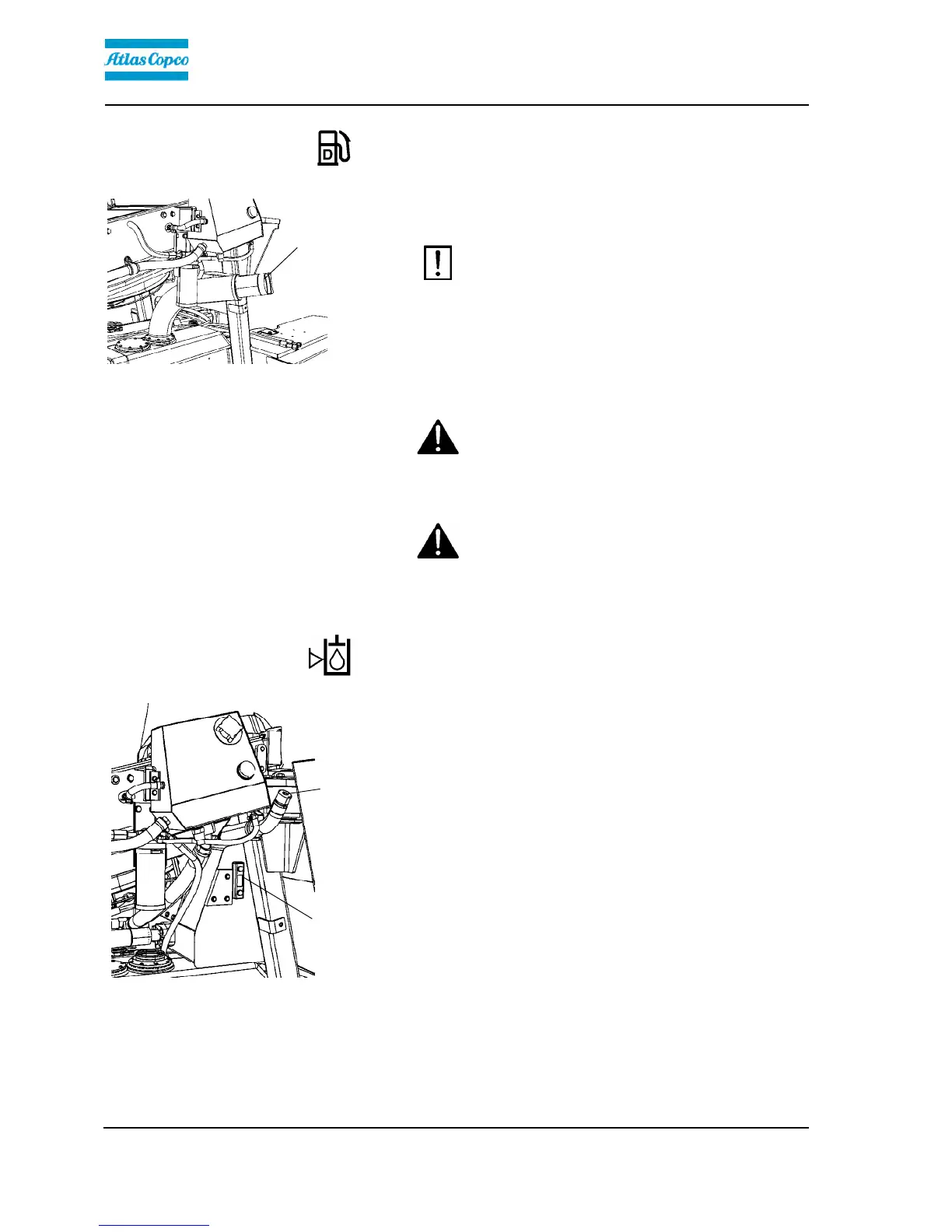

Fig. Hydraulic reservoir

1. Sight glass

2. Filler pipe

1

2

Place the roller on a level surface and check that the

oil level in the sight glass (1) is between the max and

min markings.

Top up with the type of hydraulic fluid specified in the

lubricant specification, if the level is too low.

The volume between the min. and max. lines is

approx. 4 liters (4.2 qts).

98

Loading...

Loading...