Maintenance - 500 / 1500h

4812160001_A.pdf2014-08-25

Radiator - Check/Cleaning

Fig. Engine compartment

1. Water cooler

2. Charge air cooler

3. Hydraulic fluid cooler

4. Condenser element AC (Optional)

5. Screws (x 2)

1

2

3

4

5

5

Check that air can pass unobstructed through the

radiators (1), (2) and (3).

Clean a dirty radiator using compressed air or a

high-pressure water jet.

Undo the two screws (5) and tilt the condenser

element upwards.

Blow air or direct water through the cooler in the

opposite direction to that of the cooling air.

Be careful when using a high-pressure washer -

do not place the nozzle too close to the radiator.

Be careful when using a high-pressure washer -

do not place the nozzle too close to the radiator.

Wear protective goggles when working with

compressed air or high-pressure water jets.

Wear protective goggles when working with

compressed air or high-pressure water jets.

Drum cartridge - Checking the oil level

Fig. Left drum side

1. Groove

1

Position the roller on a flat surface with the groove (1)

on the inside of the drum aligned with the top of the

drum frame.

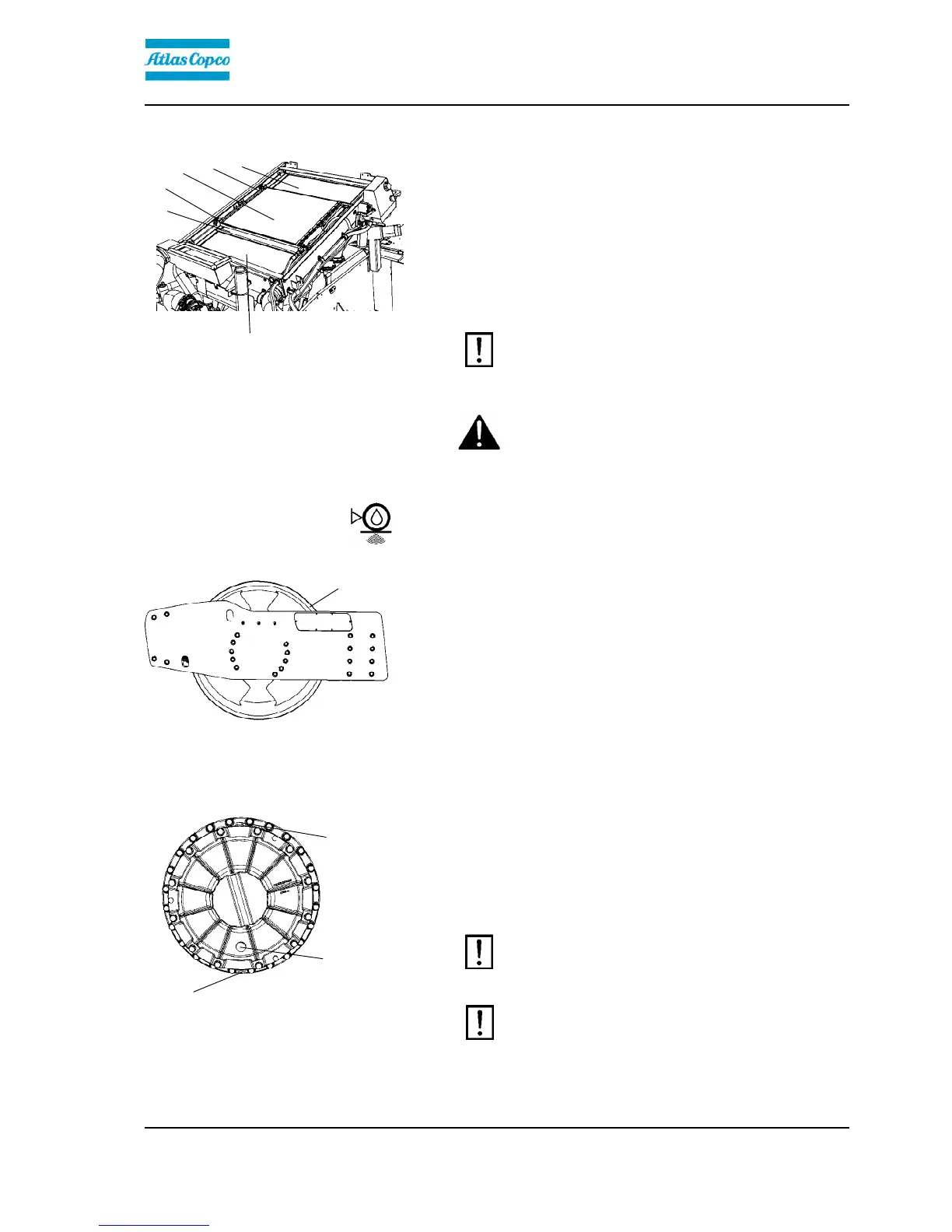

Fig. Left drum side

1. Filler plug

2. Drain plug

3. Sight glass

1

2

3

The oil should now come up to the sight glass (3).

If necessary, release the filler plug (1) and fill to half

the sight glass (3).

Clean the magnetic filler plug (1) of any metallic

residue, before refitting the plug.

Ensure that only AtlasCopco Drum Oil 1000 is

used in the cartridges.

Ensure that only AtlasCopco Drum Oil 1000 is

used in the cartridges.

Do not overfill with oil - risk for overheating.Do not overfill with oil - risk for overheating.

Now repeat the procedure on the opposite side of the

113

Loading...

Loading...