Maintenance - 500 / 1500h

4812160001_A.pdf 2014-08-25

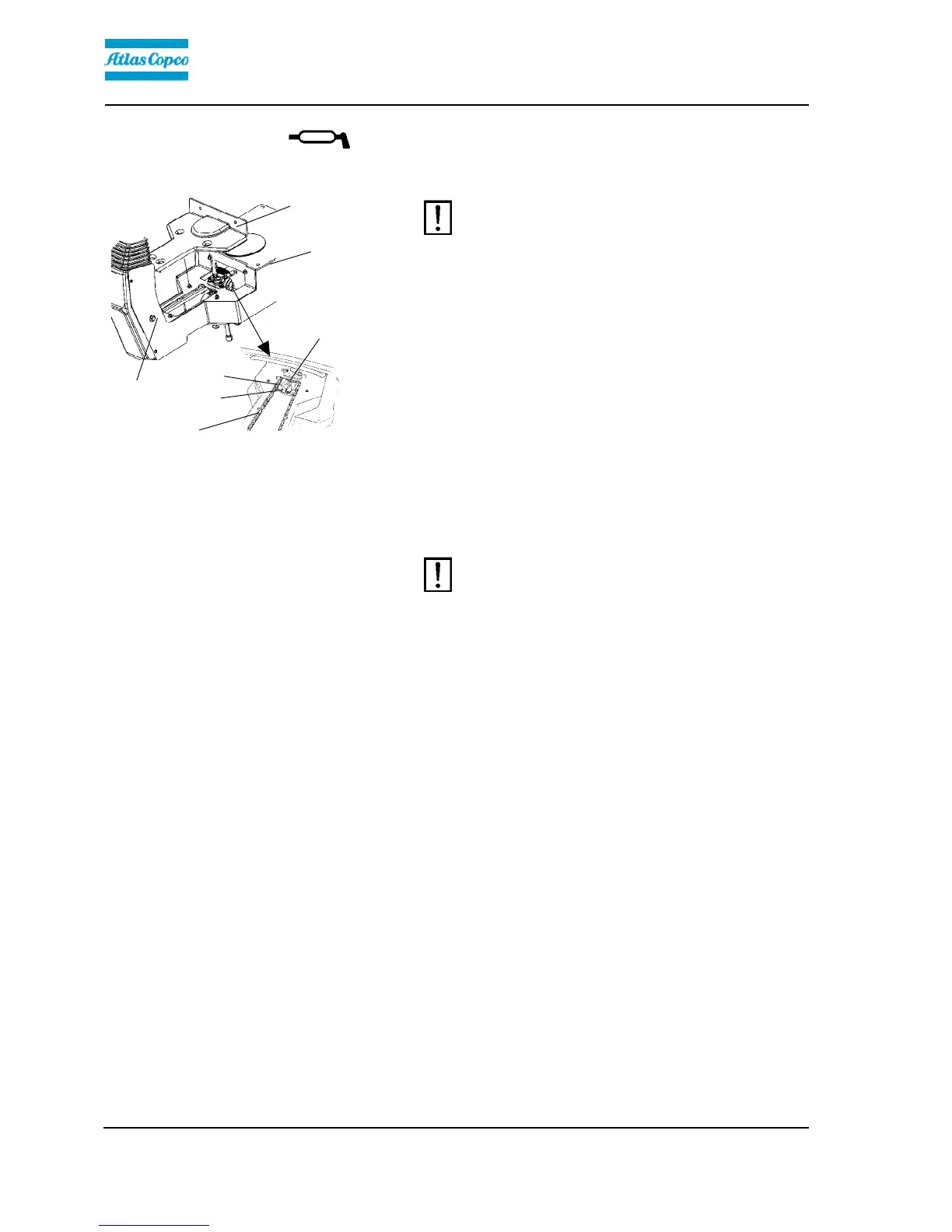

Seat bearing - Lubrication

2

3

1

6

4

Figure. Seat bearing

1. Grease nipple

2. Gearwheel

3. Steering chain

4. Adjusting screw

5. Cover

6. Slide rails

7. Marking

7

5

Keep in mind that the chain is a vital part of the

steering mechanism.

Keep in mind that the chain is a vital part of the

steering mechanism.

Remove the cover (5) to access the lubrication nipple

(1). Lubricate the operator seat slew bearing with three

strokes of a hand-operated grease gun.

Clean and grease the chain (3) between the seat and

the steering column.

Also grease the seat slide rails (6).

If the chain is slack on the sprocket (2), loosen the

screws (4) and move the steering column forward.

Tighten the screws and check chain tension.

No not tension the chain too tightly. It should be

possible to move the chain about 10 mm (0.4 in) to the

side with a forefinger/thumb at the marking (7) in seat

frame. Fit the chain lock at the bottom.

If the seat starts to be stiff when adjusting, it

should be lubricated more often than specified

here.

If the seat starts to be stiff when adjusting, it

should be lubricated more often than specified

here.

118

Loading...

Loading...