8 Application Instructions API 100-149

DVP-PLC Application Manual

8-27

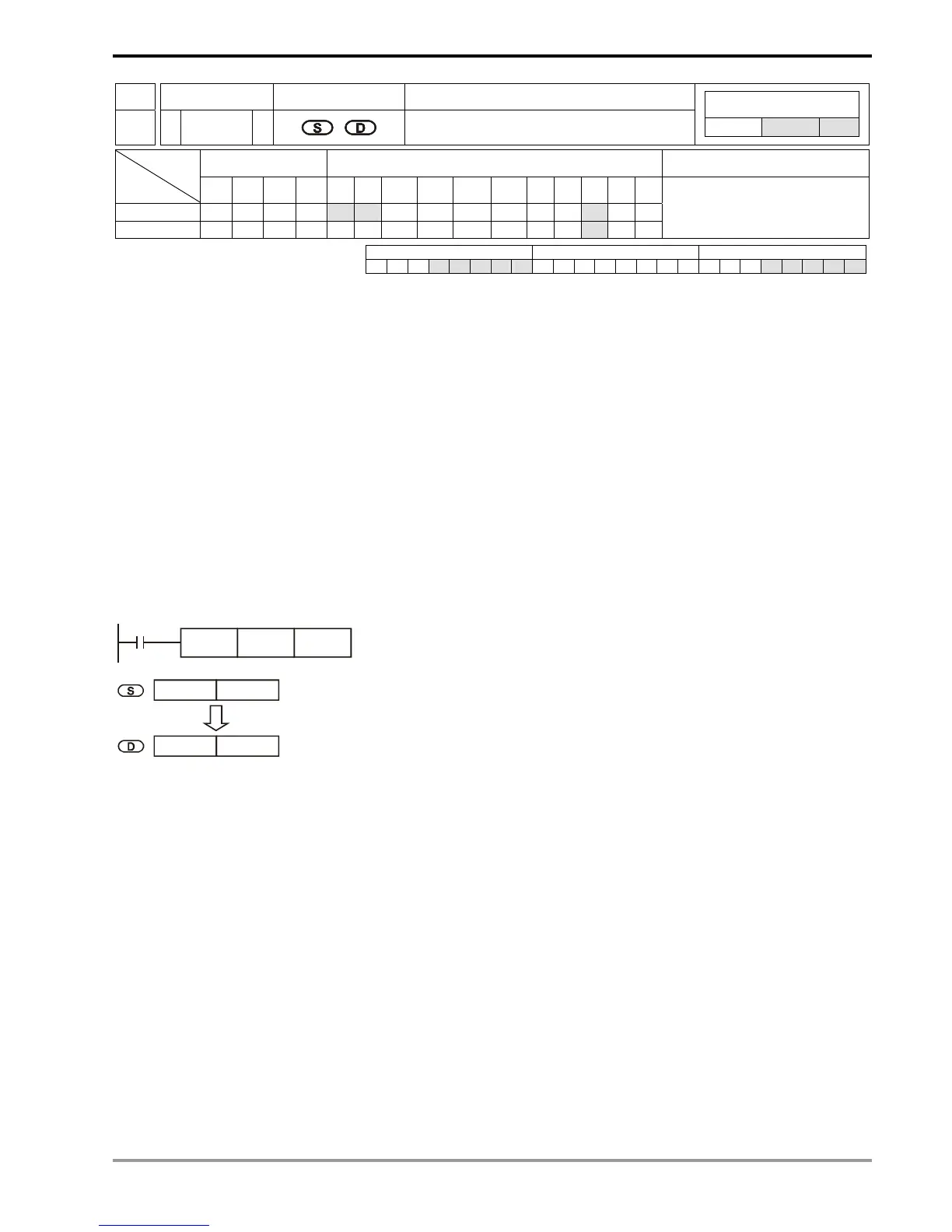

API

Mnemonic Operands Function

117

D DEG P

Radian Angle

Controllers

ES/EX/SS SA/SX/SC EH/SV

Bit Devices Word Devices Program Steps Type

OP

X Y M S K H KnX KnY KnM KnS T C D E F

S * * *

D *

DDEG, DDEGP: 9 steps

PULSE 16-bit 32-bit

ES EX SS SA SX SC EH SV ES EX SS SA SX SC EH SV ES EX SS SA SX SC EH SV

Operands:

S: Source (radian) D: Result (angle)

Explanations:

1. See the specifications of each model for their range of use.

2. Flags: M1020 (zero flag); M1021 (borrow flag); M1022 (carry flag)

3. Degree = radian × (180/

π)

4. If the absolute value of the result > maximum floating point available, the carry flag M1022 = On.

5. If the absolute value of the result < minimum floating point available, the borrow flag M1021 = On.

6. If the result = 0, the zero flag M1020 = On.

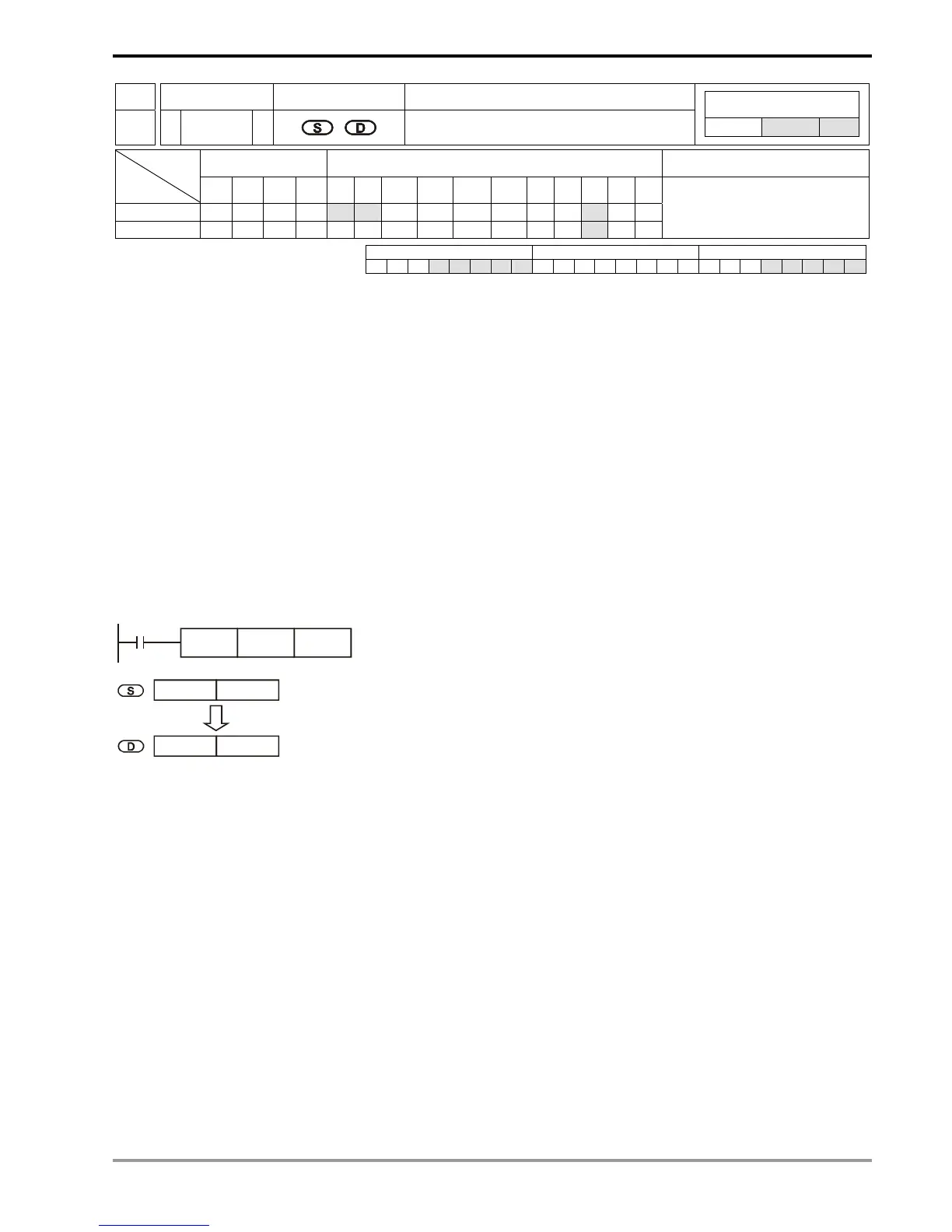

Program Example:

When X0 = On, designate the angle of binary floating point (D1, D0). Convert the radian into angle and store the

result in binary floating point in (D11, D10).

X0

DDEG D0 D10

D 1 D 0

D 11 D 10

binary floating point

Angle (radian 180/ )

X

π

Radian

binary floating point

Remarks:

For floating point operations, see “5.3 Handling of Numeric Values”.

Loading...

Loading...