11 G-code Application

DVP-PM Application Manual

11-16

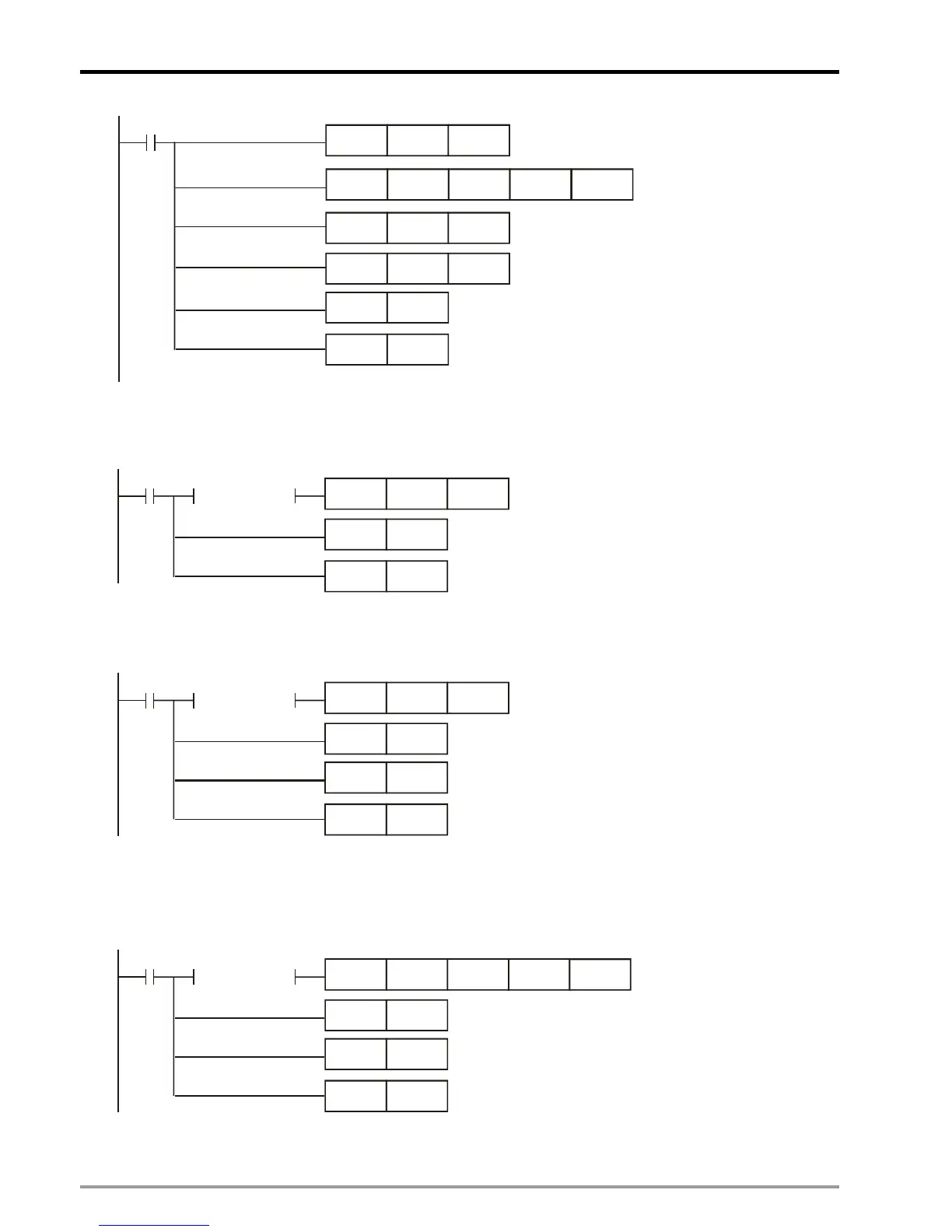

M0

TO

K255 K0

MOV

K50 D3000

MOV

K10

D3001

Specify Group with 10 groups

Initialize the file

conversion process

Specify length of recipe

with 50 words

K0 K1

MOV

K1 D66

SET

M24

RST

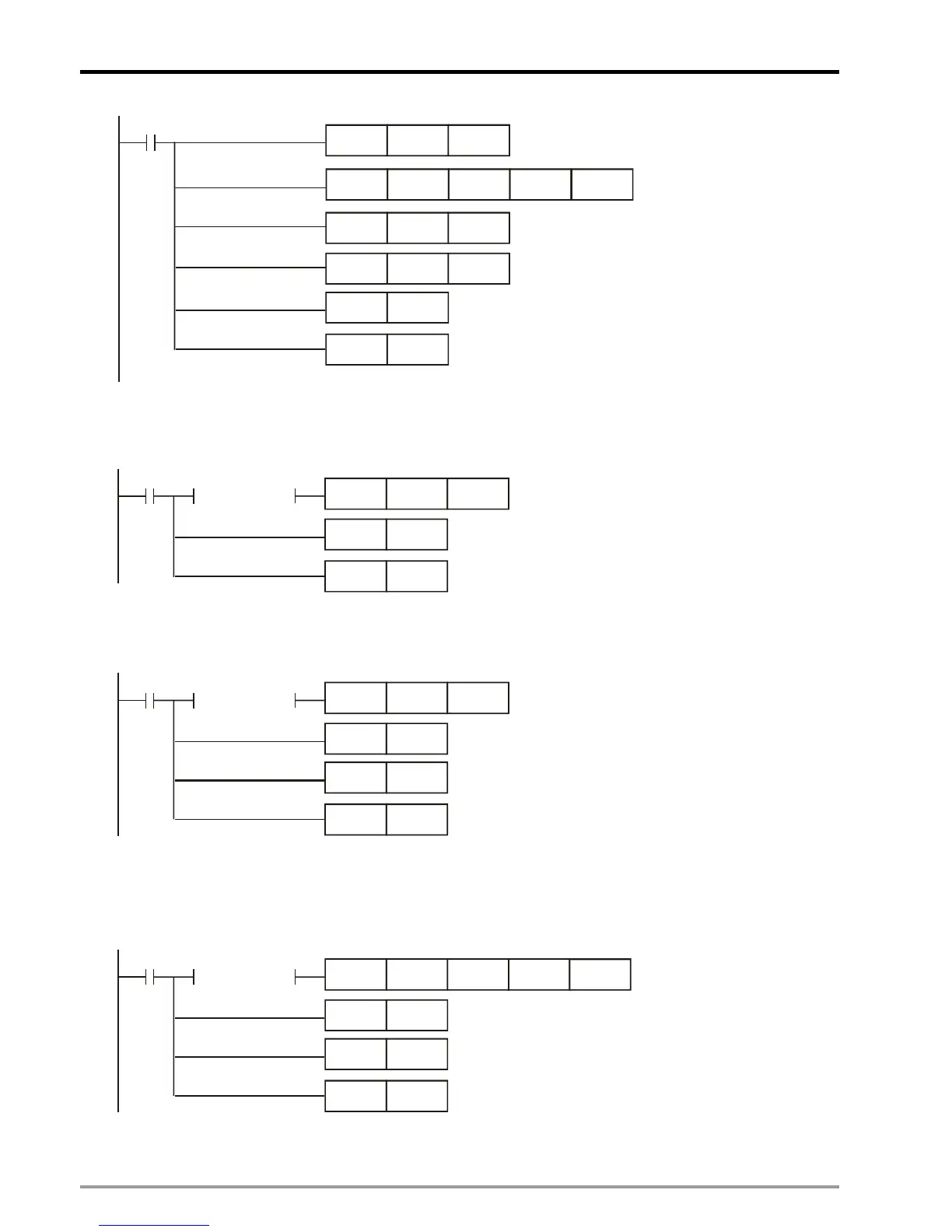

M0

Step 2: HMI reads the value in D65 as the command to control the recipe. D65 = 1 indicates changing the

recipe group number.

M24

MOV

K1 D65

SET

M25

RST

M24

LD= D65 K0

Step 3: When recipe group number is changed, the value in D65 becomes 0. After this, write in the recipe

command to download next group and increase the recipe group number in D66.

M25

MOV

K4

D65

SET

M26

RST

M25

LD=

D65 K0

INCP

D66

Step 4: The value in D65 will be cleared as 0 every time when modified. When one group of recipe is

received, conduct file conversion to convert the received data into ASCII codes and store the converted data

inD3002~D3502. When the above process is completed, repeat the step to download the next group.

M26

TO

K255

K2

RST

M26

SET

M24

LD=

D65 K0

SET

M27

D3000 K1

Step 5: If errors occur in file conversion, D3000 will store the error code 0xffff. Users can stop the next

Loading...

Loading...