Maintenance

Printed in U.S.A. 141 50940411/G0219

Hydraulic Hose Maintenance

Hydraulic hoses and connections must be

inspected by a trained technician before the first

use of the machine, and at least annually

thereafter, for leaks and/or damage.

Leakages and damaged pressure hose/lines

must be immediately repaired or replaced by an

authorized service center.

Never use your hands to check for suspected

hydraulic leaks. Always use a piece of wood or

cardboard.

Leaks from hydraulic hoses or pressurized

components can be difficult to see, but

pressurized oil can have enough force to pierce

the skin and cause serious injury.

Obtain immediate medical attention if

pressurized oil pierces the skin. Failure to

obtain prompt medical assistance could result

in gangrene or other serious damage to tissue.

Always relieve hydraulic system pressure

before performing any maintenance on the

machine. Do not tighten leaking connections

when the hydraulic system is under pressure.

Never weld or solder damaged or leaking

pressure lines and/or screw connections.

Always replace damaged hydraulic

components.

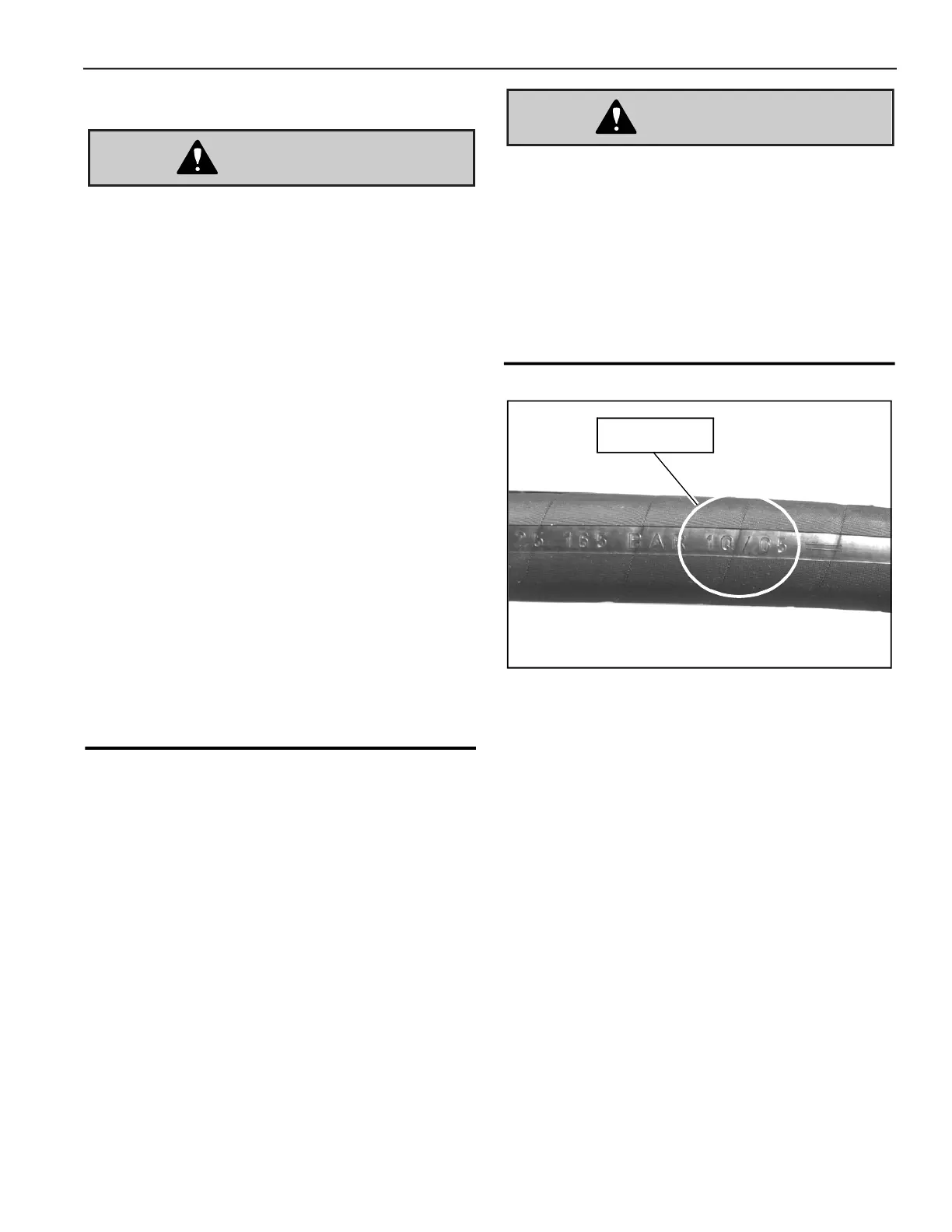

Hydraulic hoses must be replaced every six

years from the date of manufacture, even if they

do not appear damaged. The date of

manufacture (month or quarter and year) is

indicated on hydraulic hoses. See Fig. 147.

Fig. 147 – Hydraulic Hose Manufacture Date

1 Q/05

Loading...

Loading...