COMMISSIONING

140 Service Manual Part No.: 4417340 Revision 1

954 SmartServo FlexLine

• W&M Sealing

1

: This board can be electronically s ealed

via the software. A Notified Body can set his password via

[W&M notified body seal password]. He can apply the seal by

setting [W&M seal]. Here some data logging is filled in and

the related password. This requires a W&M module for

Engauge.

If the primary value of the product temperature is completely

valid, then a W&M indication will be set (e.g. visible in HART

SmartView).

Unsealing: give the [W&M unseal level 1] and [W&M unseal

the level 2] commands successively.

History can be made visible via [W&M seal history].

7.3.8.4 Commissioning

7.3.8.4.1 Commissioning Parameters for 1 or 2 RTDs (3- and 4-wire) Temperature

Calculations

NOTE: Make sure the RTD/MPT jumper is set to RTD.

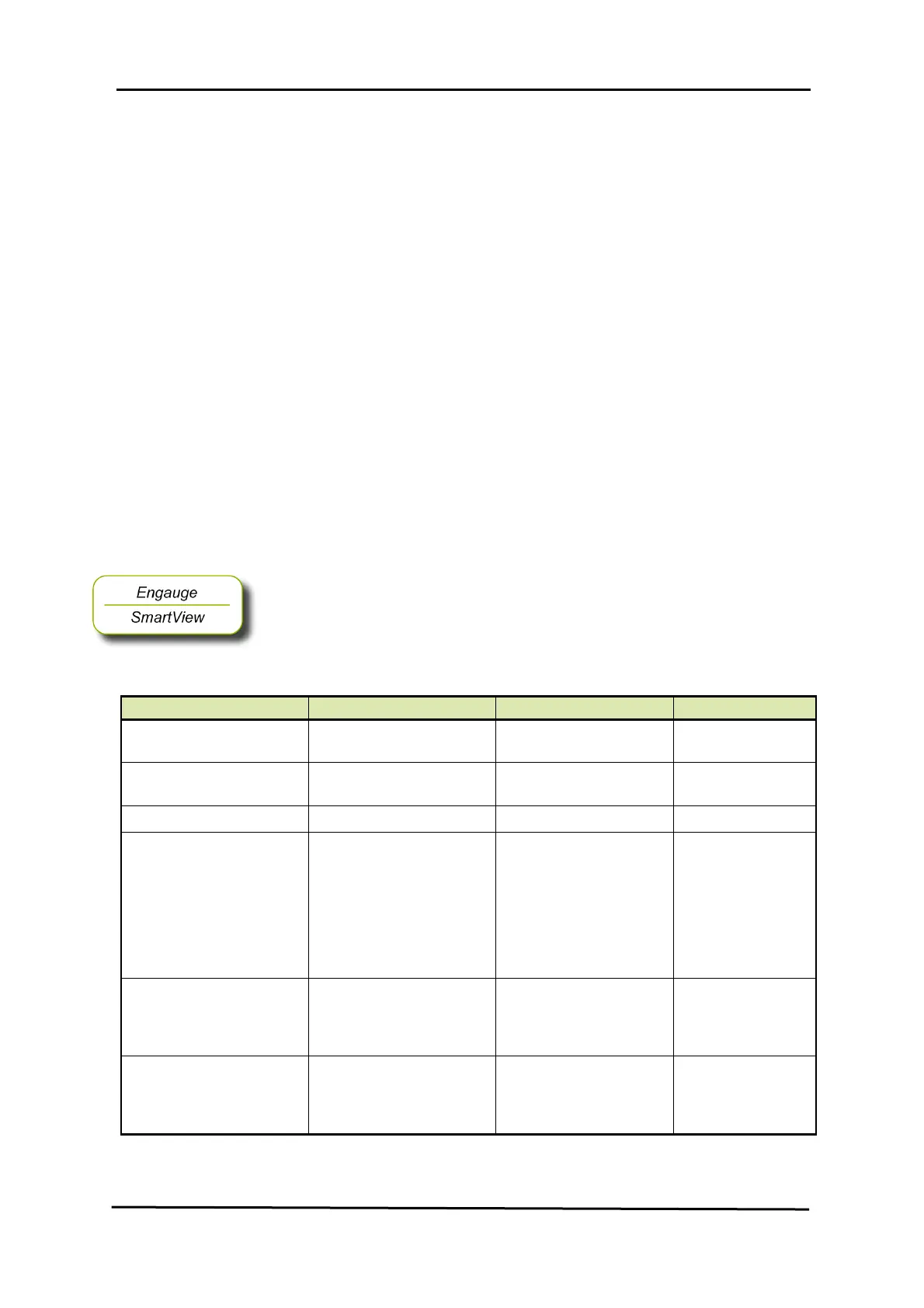

☛ The following entities must be set by Engauge or HART

SmartView for a correct functioning of the FII-RTD module in

an instrument. The default values are available after

initialization of the non-volatile memory.

Name Explanation Value Range Default

[Lowest element offset]

The distance from tank zero

till the first RTD

floating point number:

<-x.x .. +x.x>

<80.0>

[Second element offset]

if applicable

The distance from tank zero

till the second RTD

floating point number:

<-x.x .. +x.x>

<0.0>

[Number of elements]

The number of RTDs used

<1..2>

<0>

[Element type]

The type (material) of the

used RTDs

<Pt100 large + small>

<Ni191>

<PtCu100>

<Cu100>

<Cu90 enraf + beacon + weston/

solartron/nulectrohms>

<Sangamo MRT>

<Sangamo spot>

<No type>

[Measurement type] Selects RTDs, MPT, or

MRT.

<RTD 3wire>

<RTD 4wire>

<MPT>

<MRT>

<No type>

[RTD configuration]

Selects how the RTDs are

positioned.

<RTD1 in tank>

<RTD1 and RTD2 in tank>

<RTD1 in tank and RTD2

ambient> <RTD1

<No configuration>

Loading...

Loading...