MAINTENANCE

Part No.: 4417340 Revision 1 Service Manual 261

954 SmartServo FlexLine

Run-down test

With the run-down test one can estimate the state of the bearings and

the presence of obstructions over a certain range. The command will fill

data arrays containing maximum and minimum measured frequency

over 140 segments. Those segments are equally distributed between

the start and stop position of the test. So, the segment size will be

smaller when the range is smaller (with a minimum of 2 cm). By

decreasing the range, one can zoom in on a certain part of the range.

Entity name Value Range Default Value Explanation

Run down start position

27.0 m

Starting position of the run-down

test. The displacer will go up and

stop at this position or at motor limit

high, whichever comes first.

Run down stop position

0 m

Stop position of the run-down test.

The run-down test will be

terminated at this position or at the

product interface, whichever comes

first.

Run down

Starts the run-down test. When the

run-down test is terminated, the

gauge will perform the default

operation.

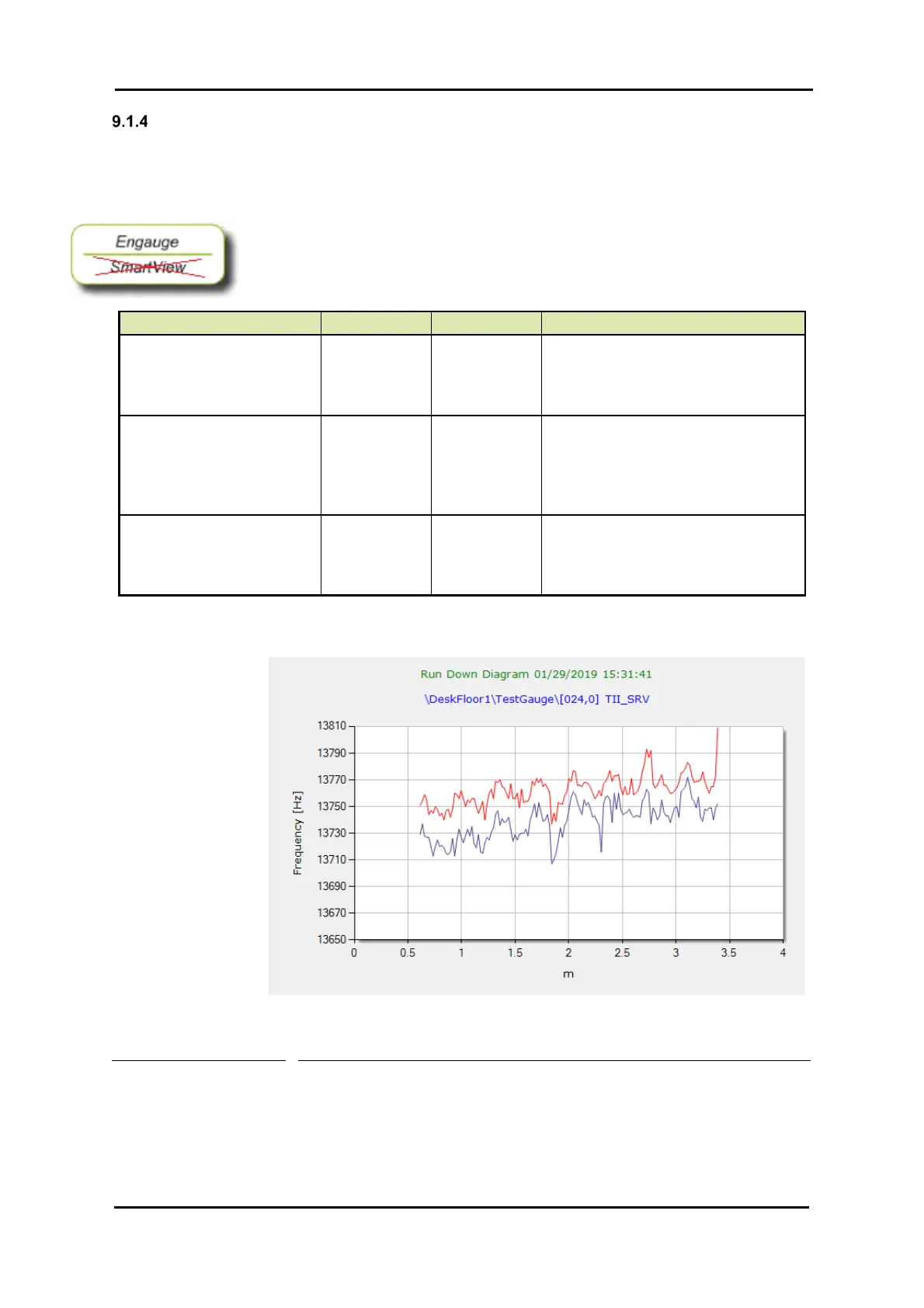

The result of the run-down test can only be viewed graphically by the

diagram viewer in Engauge (Run Down Diagram).

Figure 9-4 Example of a smooth run-down diagram (segment size ~3 cm)

Figure 9-4 shows an example of a smooth run-down test over a small

distance. Because of the small segment size, a 0.34m pattern is visible

which is caused by the drum circumference (drum unbalance).

Loading...

Loading...