TYPICAL PAGE - D

Two pulse hoses connect the pump to pulse fit-

tings

on

the front of the cylinder/crankcase.

• V4 Models - cylinders 1 and 3

• V6 Models - cylinders 1 and 4

Typ

ica

l

illu

s

tr

a

ti

on

for

lower

puls

e

ho

se

of

the oil sup-

V4

or

V6

Mode

ls

lift pump. A pressure-sensing

switch monitors

oil injection pressure.

Oil Injector-Manifold

Cp.n:lnlllllQ.DlS~---,

• 40 V oil injector

Cross

r

efe

ren

ces

• Oil distribution manifold

direct

read

ers

to

related

to

pi

cs

• Oil pressure switch

• Pressure regulator (oil return hose)

• Oil distribution hoses

• Oil to fuel check valve

3

3

2

1

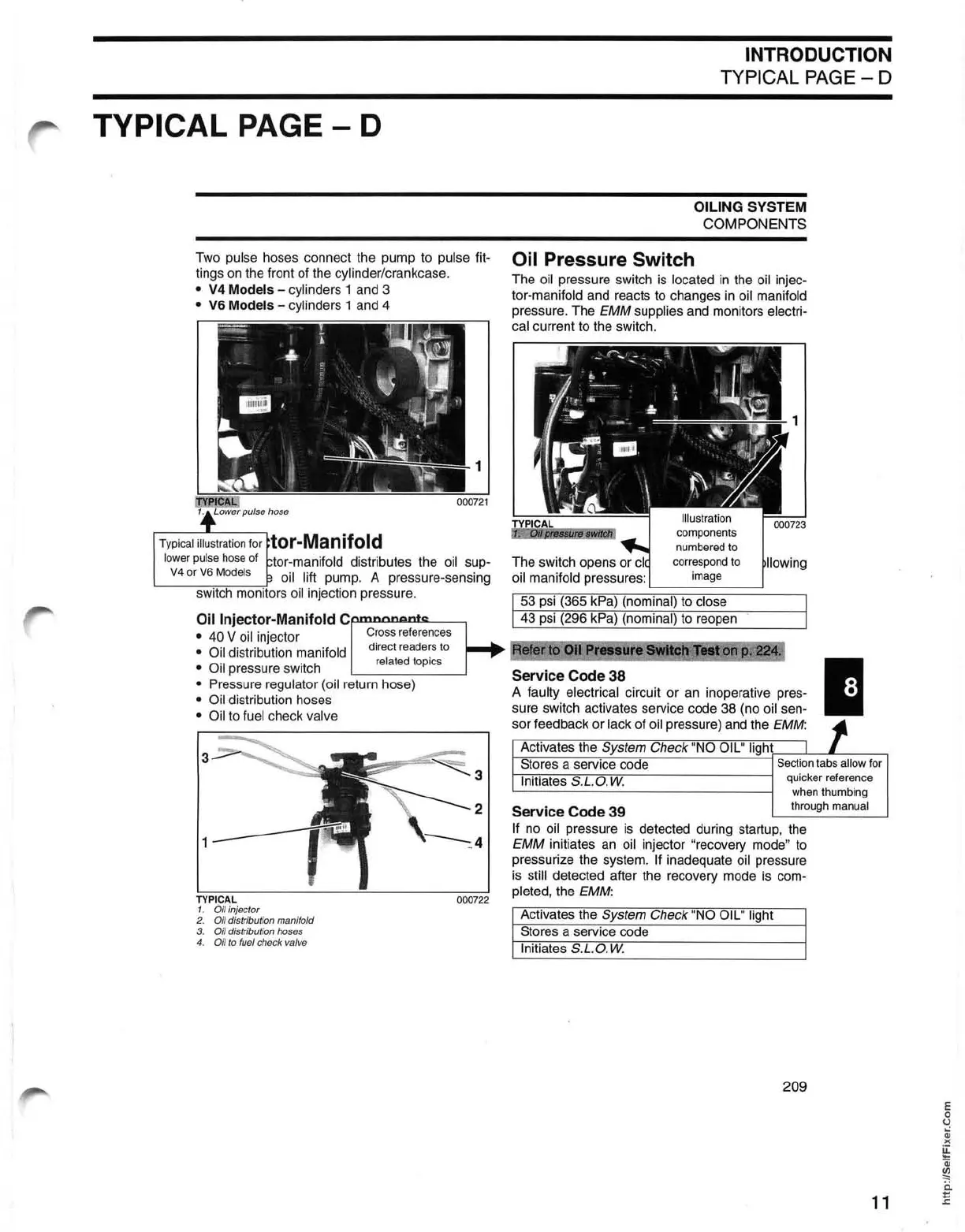

TYPICAL

1. Oil injector

2.

Oil distribution manifold

3.

Oil distribution hoses

4.

Oil

to

fuel check valve

INTRODUCTION

TYPICAL PAGE - D

OILING SYSTEM

COMPONENTS

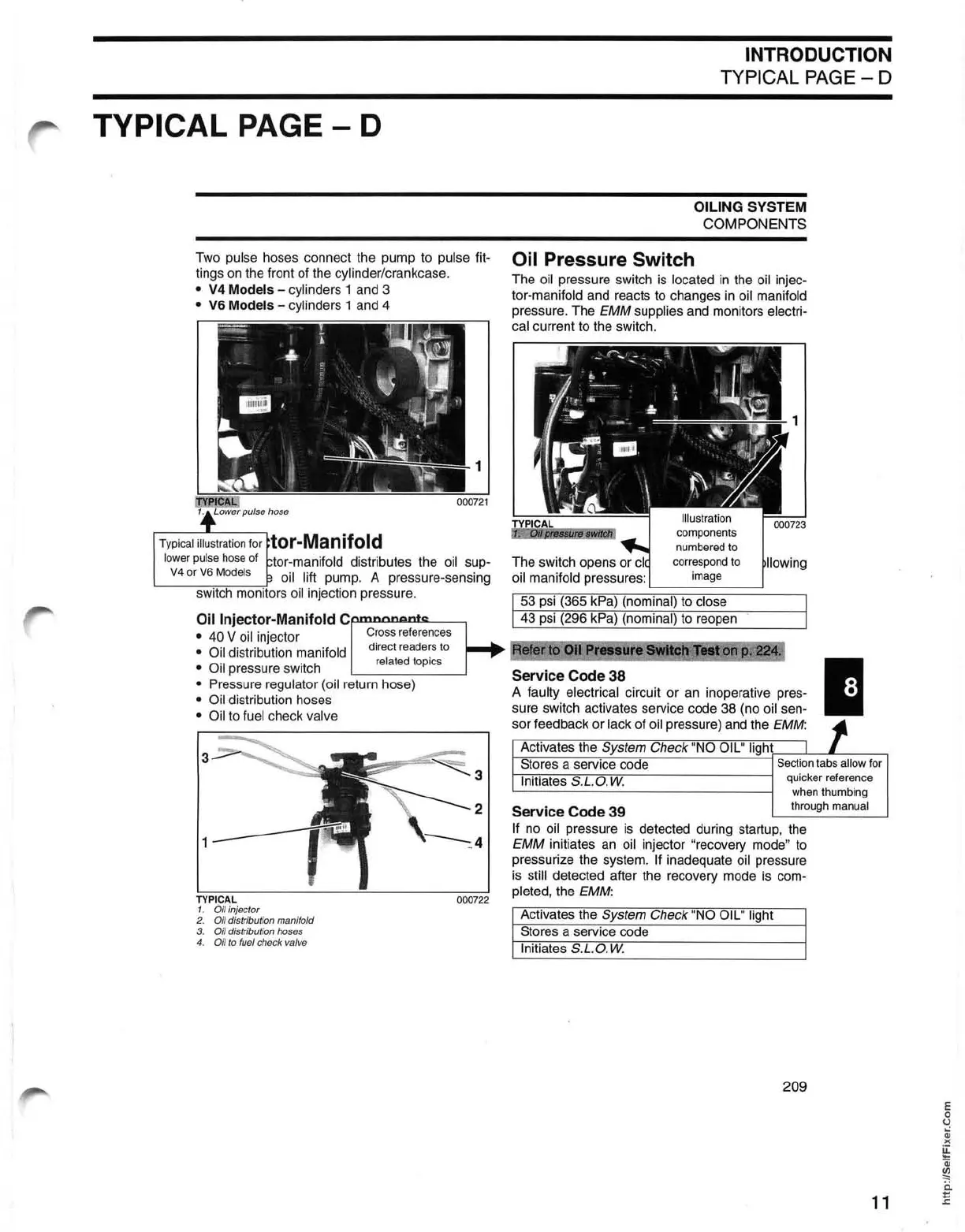

Oil Pressure Switch

The oil pressure switch is located

in

the oil injec-

tor-manifold and reacts to changes

in

oil manifold

pressure. The

EMM

supplies and monitors electri-

cal

current to the switch.

components

numbered

to

The switch opens

or

correspond

to

oil manifold pressures:

image

53 psi (365 kPa) (nominal) to close

43 psi

(296 kPa) (nominal) to reopen

Service Code 38

A faulty electrical circuit or

an

inoperative pres-

sure switch activates service code

38

(no oil sen-

sor feedback

or

lack

of

oil pressure) and the EMM:

Activates the System Check "NO OIL" light

I

I

1

Stores a service code

Section

tabs

allow

for

Initiates S.L.O.

W.

quicker

reference

when

thumbing

Service Code 39

through

manua

l

If

no oil pressure

is

detected during startup, the

EMM

initiates an oil injector "recovery mode" to

pressurize the system.

If inadequate oil pressure

is

still detected after the recovery mode

is

com-

pleted, the EMM:

Activates the System Check "NO OIL" light

Stores a service code

Initiates S.L.O.

W.

209

E

o

o

W

)(

~

Qj

~

i:i

11

~

Loading...

Loading...