GEARCASE

REMOVAL AND INSTALLATION

Installation

9.9/15 MODELS

IMPORTANT:

On

models with a gearcase

extension kit, make sure the driveshaft tube

extension, water tube extension, and gearcase

exhaust

seals are

in

place.

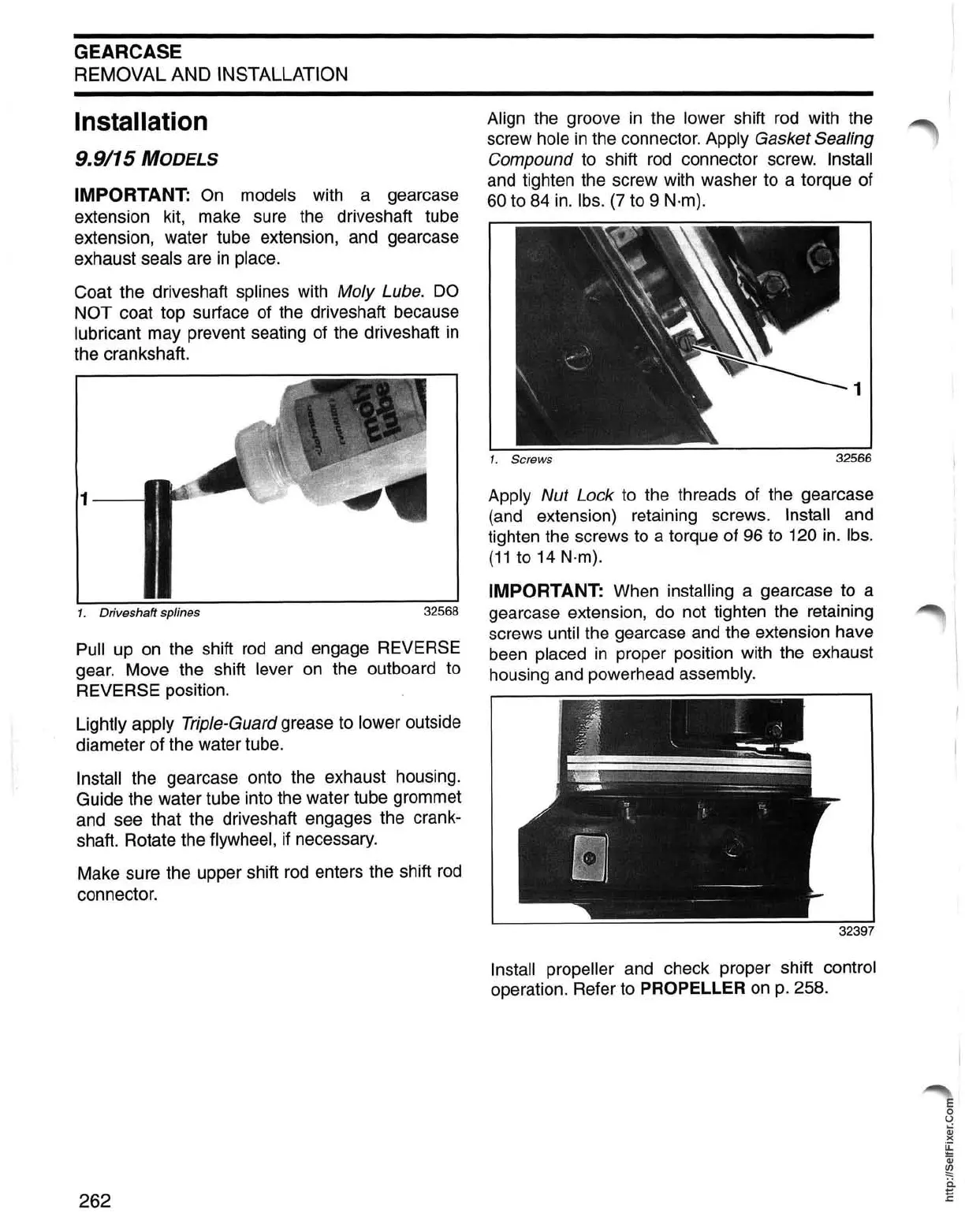

Coat the driveshaft splines with Moly Lube.

DO

NOT coat top surface of the driveshaft because

lubricant may prevent seating of the driveshaft

in

the crankshaft.

1. Driveshaft splines

Pull

Up

on

the shift

rod

and

engage REVERSE

gear. Move the shift lever

on

the outboard to

REVERSE position.

Lightly apply Triple-Guard grease

to

lower outside

diameter of the water tube.

Install the gearcase onto the exhaust housing.

Guide the water tube into the water tube grommet

and see that the driveshaft engages the crank-

shaft. Rotate the

flywheel, if necessary.

Make sure the upper shift

rod

enters the shift

rod

connector.

262

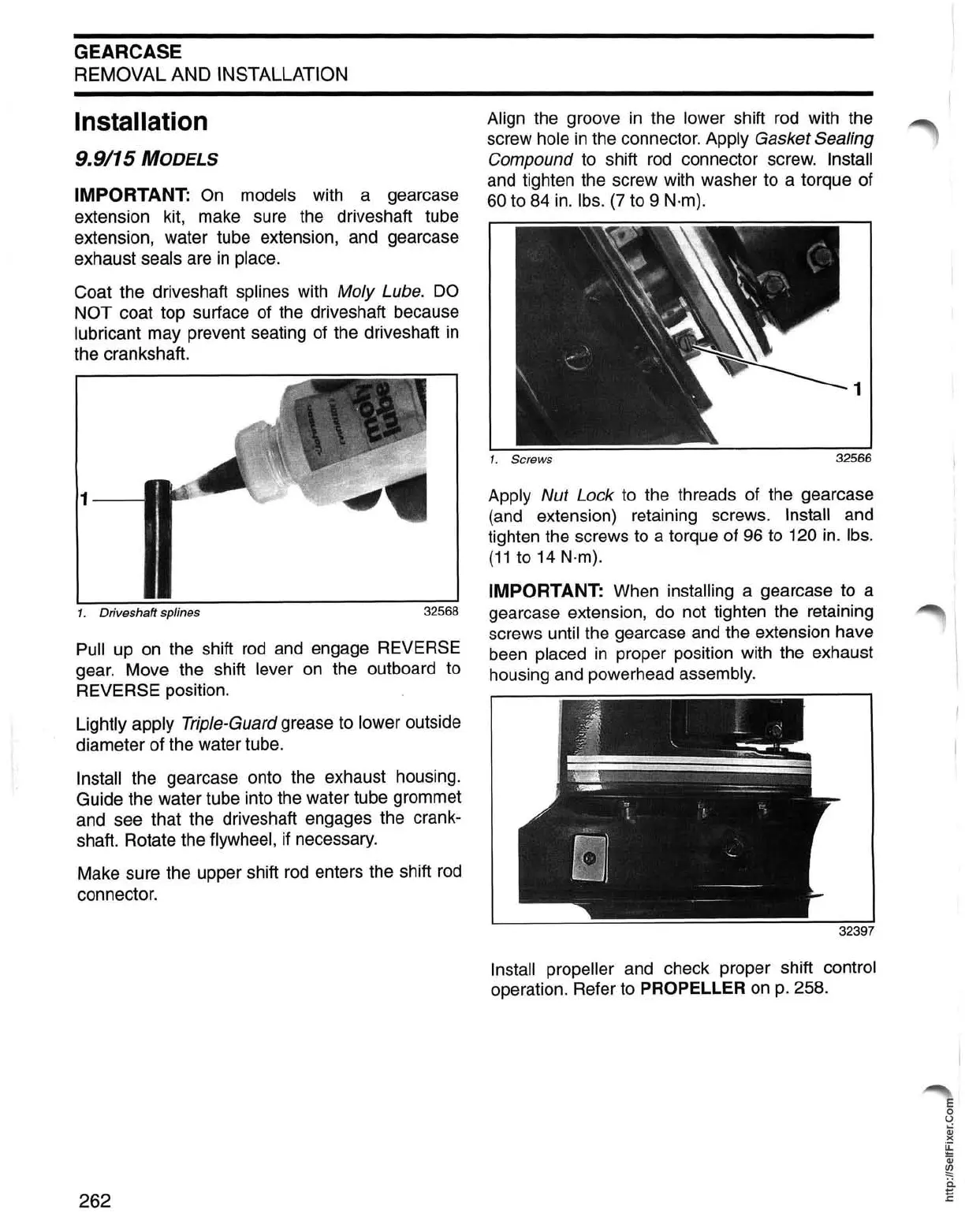

Align the groove

in

the lower shift

rod

with the

screw

hole

in

the connector. Apply Gasket Sealing

Compound to shift

rod

connector screw. Install

and tighten the screw with washer to a torque of

60

to

84

in.

Ibs

.

(7

to 9 N·m).

1

1. Screws

32566

Apply Nut Lock

to

the threads of the gearcase

(and extension) retaining screws.

Install and

tighten the screws

to

a torque of 96

to

120

in

.

Ibs.

(11

to

14 N·m).

IMPORTANT: When installing a gearcase

to

a

gearcase extension, do not tighten the retaining

screws

until the gearcase

and

the extension have

been

placed

in

proper position with the exhaust

housing and powerhead

assembly.

Install propeller

and check proper shift control

operation. Refer to PROPELLER

on

p.

258.

E

o

U

Qj

)(

~

OJ

~

ii

E

Loading...

Loading...