FUEL SYSTEM

INTAKE MANIFOLD

1

1.

Screw

Inspection

IMPORTANT:

Do

not lift or bend leaf valves by

hand. This may damage them so they may not

seal properly or may break after the engine

is

returned to service.

Inspect the leaf plate assemblies for damage:

• The leaf valves and plate must not

be

distorted.

• The leaf valve tips must not be cracked or

chipped.

• The leaf stops must not

be

distorted or loose.

•

Test leaf plate screw tightness. If loose, tighten

using

Screw Lock.

• The check valve disk must

be

intact and free to

move inside the

valve. The check valve screen

must

be

clean.

2

3

1

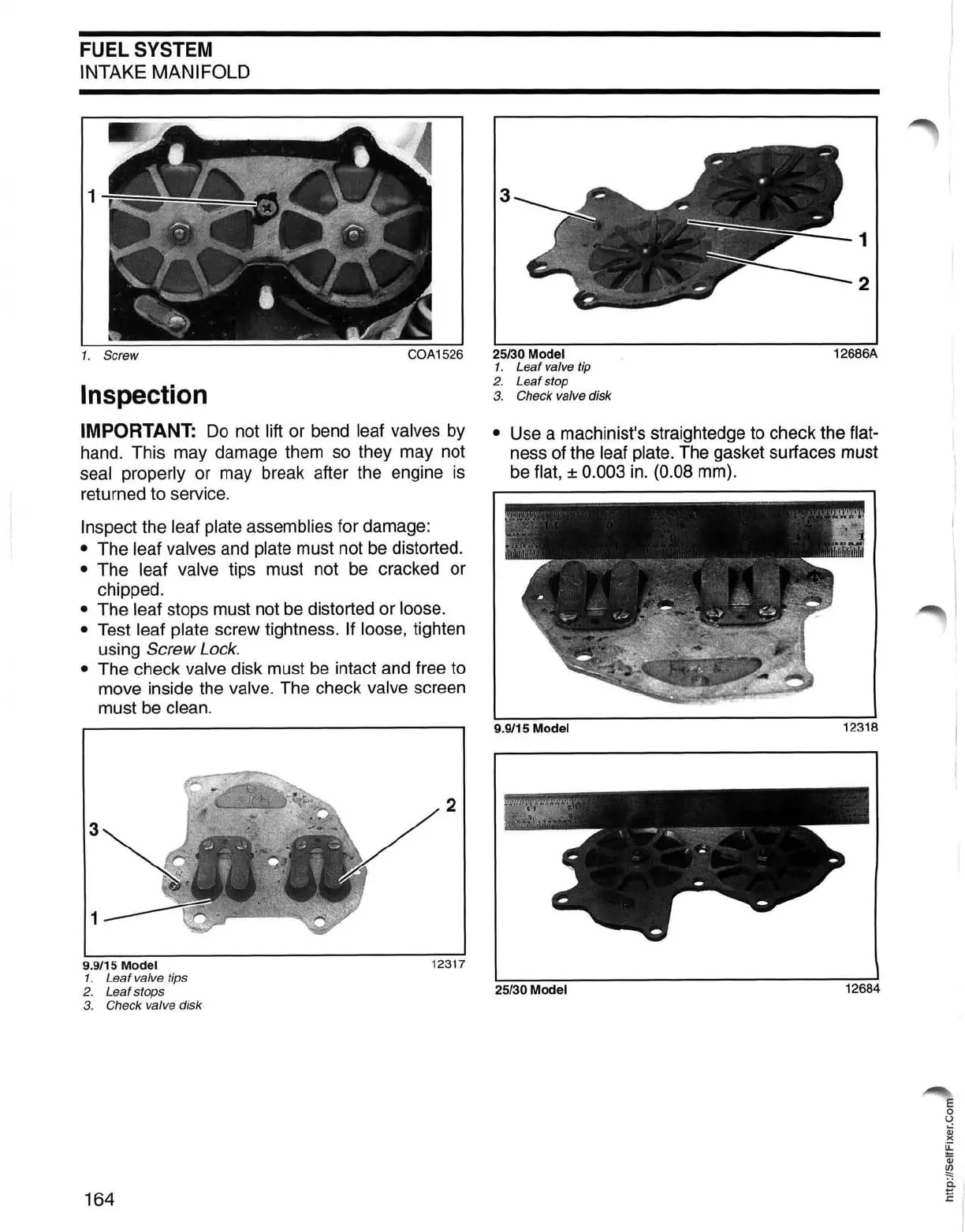

9.9/15 Model

12317

1. Leaf valve tips

2. Leaf stops

3. Check valve disk

164

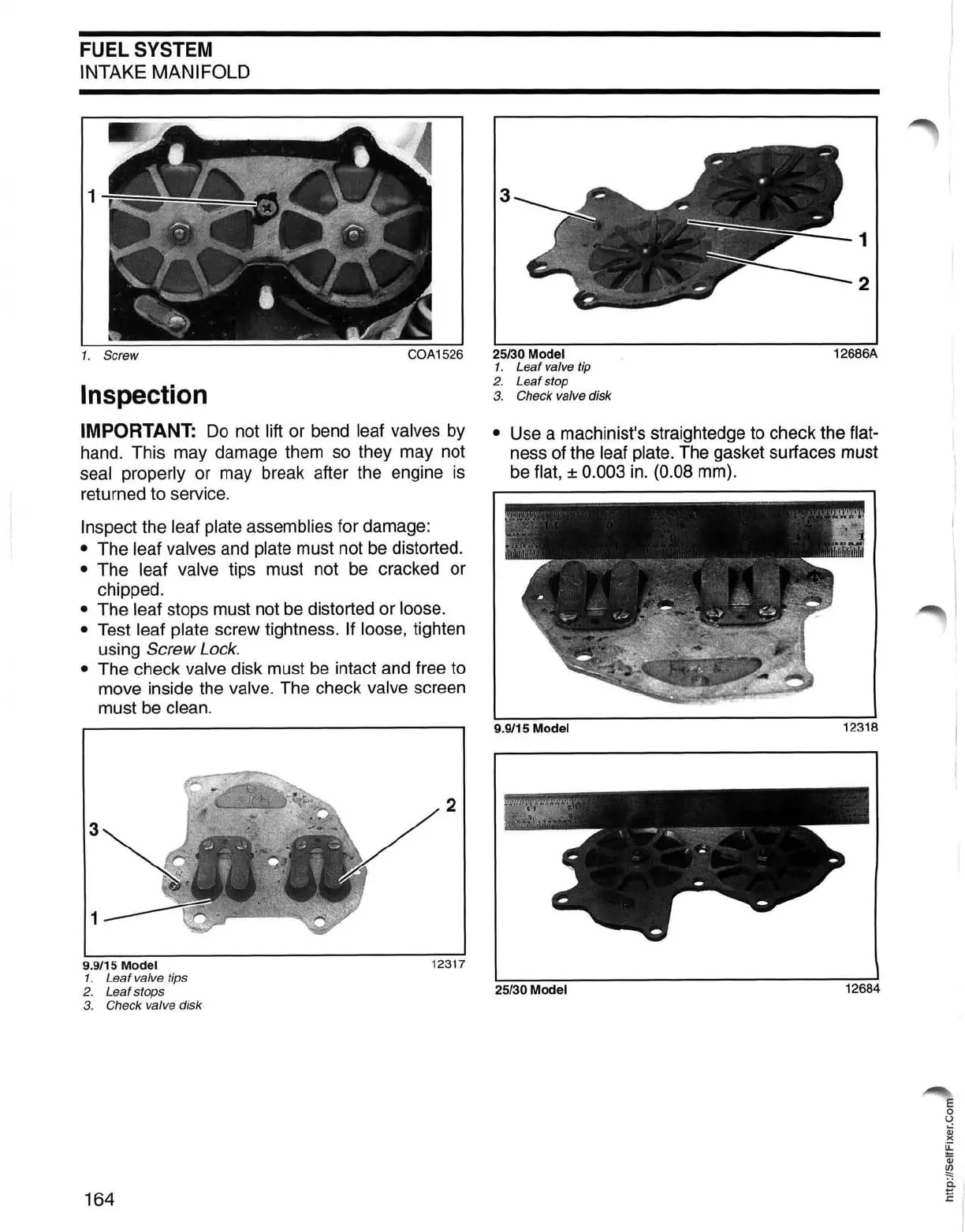

3

1

2

25/30

Model

12686A

1.

Leaf valve tip

2.

Leafstop

3. Check valve disk

• Use a machinist's straightedge to check the flat-

ness of the leaf plate. The gasket surfaces must

be

flat, ± 0.003 in.

(0

.08 mm).

9.9/15 Model

25130 Model

12684

Loading...

Loading...