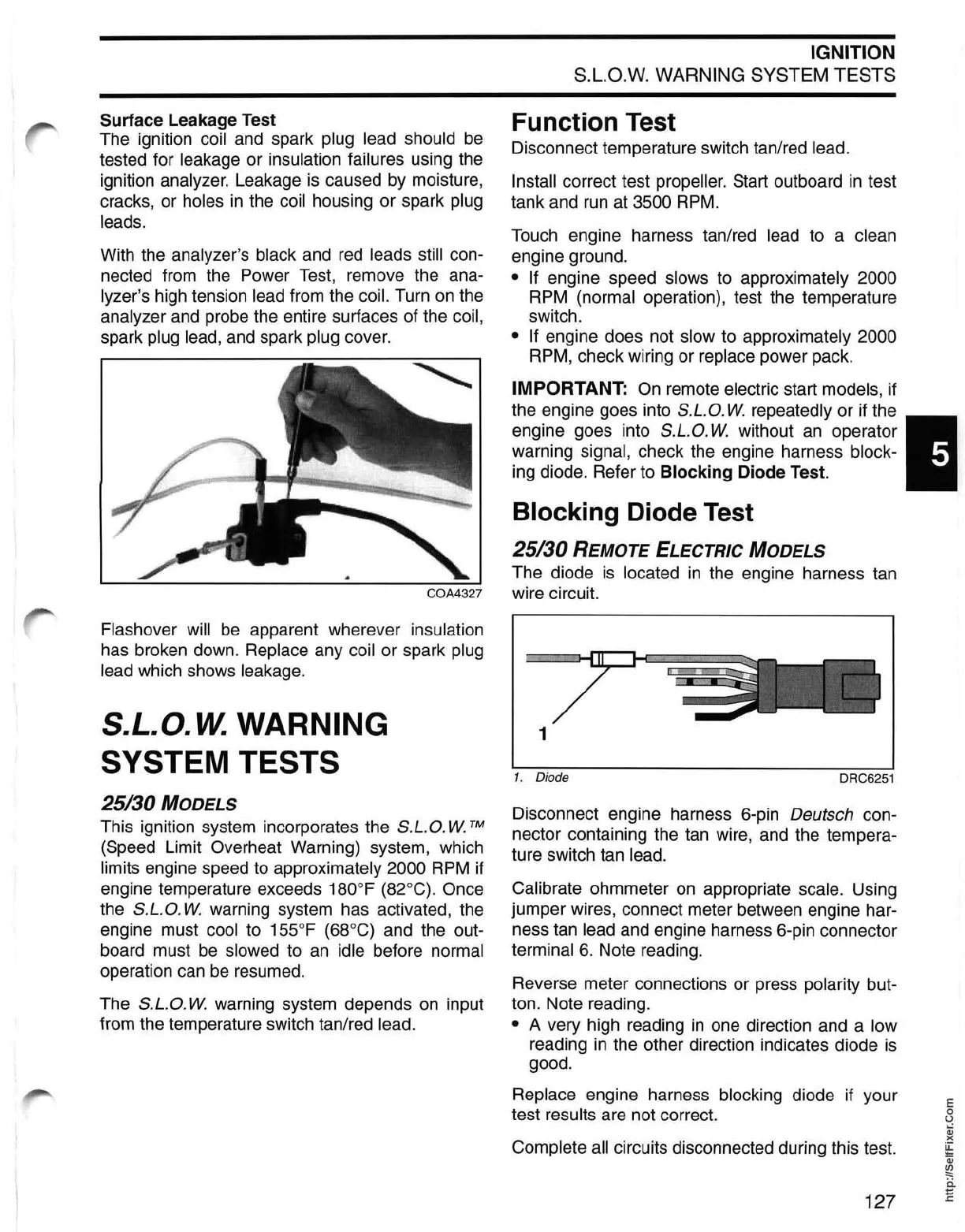

Surface Leakage Test

The ignition coil and spark plug lead should

be

tested for leakage or insulation failures using the

ignition

analyzer. Leakage

is

caused by moisture,

cracks, or

holes

in

the coil housing or spark plug

leads.

With the analyzer's black and

red

leads still con-

nected from the Power

Test,

remove the ana-

lyzer's high tension lead from the coil. Turn

on

the

analyzer and probe the entire surfaces of the coil,

spark plug lead, and spark plug cover.

Flashover will

be

apparent wherever insulation

has broken down. Replace any coil or spark plug

lead

which shows leakage.

S.L.O.

W.

WARNING

SYSTEM TESTS

25/30 MODELS

This ignition system incorporates the

S.L.O

w.

™

(Speed Limit Overheat Warning) system, which

limits engine speed to approximately 2000

RPM

if

engine temperature exceeds 180°F (82°C). Once

the

S.L.O

W.

warning system has activated, the

engine must cool to 155°F (68°

C)

and the out-

board must

be

slowed to

an

idle before normal

operation can

be

resumed.

The

S.L.O

W.

warning system depends

on

input

from the temperature switch tan/red

lead.

IGNITION

S.L.O.W. WARNING SYSTEM TESTS

Function Test

Disconnect temperature switch tan/red lead.

Install

correct test propeller. Start outboard

in

test

tank and

run

at 3500

RPM

.

Touch engine harness tan/red

lead to a clean

engine ground.

• If engine speed slows to approximately 2000

RPM (normal operation), test the temperature

switch.

• If engine does not slow to approximately 2000

RPM, check wiring or replace power pack.

IMPORTANT:

On

remote electric start models,

if

the engine goes into S.L.O.

W.

repeatedly or if the I

engine goes into

S.L.O

W.

without

an

operator

warning signal, check the engine harness block-

ing diode. Refer to Blocking Diode Test.

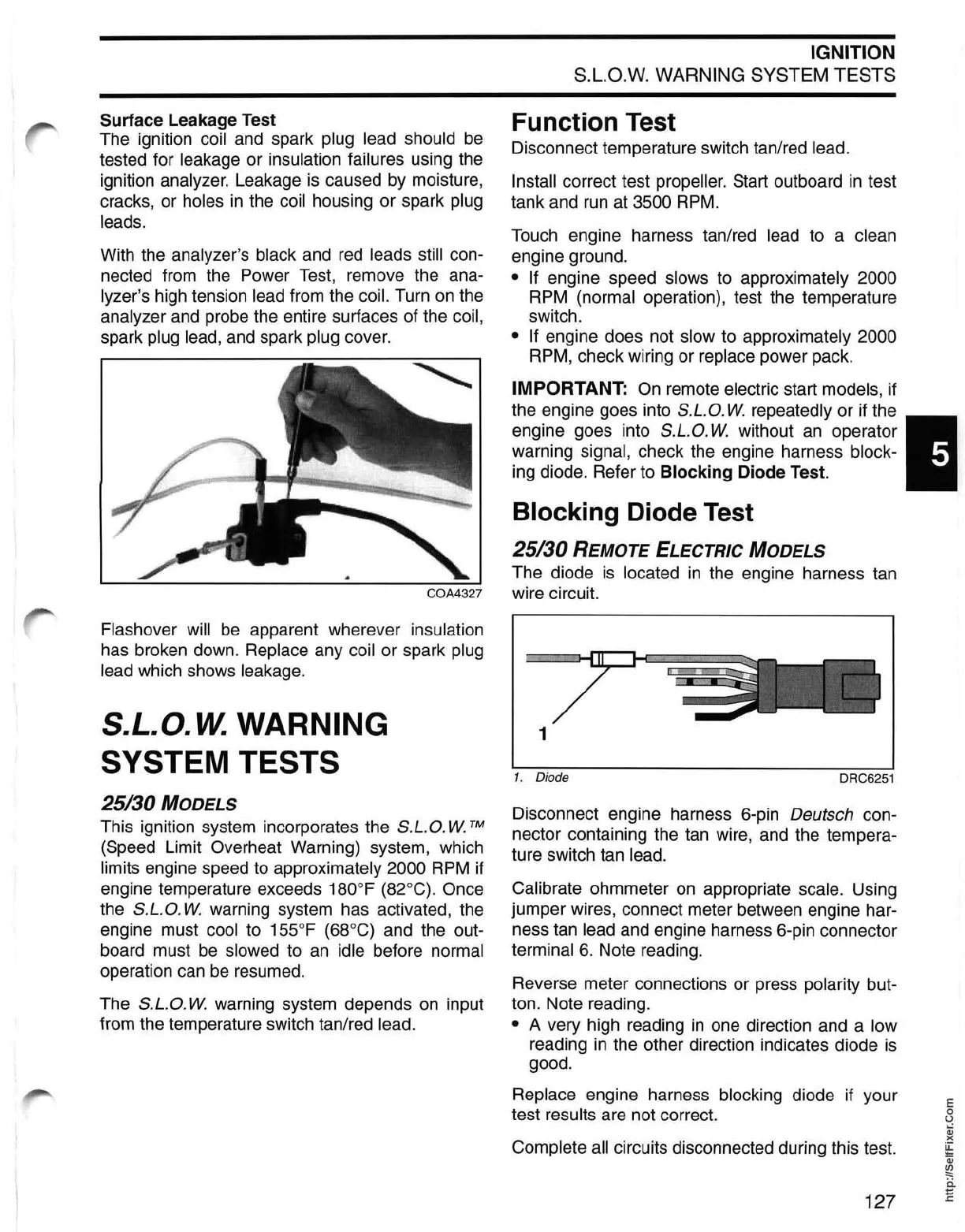

Blocking Diode Test

25/30 REMOTE ELECTRIC MODELS

The diode

is

located

in

the engine harness tan

wire circuit.

1

1. Diode

DRC6251

Disconnect engine harness 6-pin Deutsch con-

nector containing the tan wire, and the tempera-

ture switch tan

lead.

Calibrate

ohmmeter

on

appropriate scale. Using

jumper wires, connect meter between engine har-

ness tan

lead and engine harness 6-pin connector

terminal 6. Note reading.

Reverse meter connections or press polarity but-

ton. Note reading.

• A very high reading

in

one direction and a low

reading

in

the other direction indicates diode

is

good.

Replace engine harness blocking diode if your

test

results are not correct.

Complete all circuits disconnected during this test.

127

E

o

U

Qj

)(

~

Qj

~

ii

E

Loading...

Loading...