CARBURETOR MIXTURE

ADJUSTMENT

9.9/15

MODELS

IMPORTANT: Changing original factory fuel

mixture calibrations beyond the limits allowed by

the tamper resistant device

is

a violation of federal

law.

Any

needle valve adjustments beyond preset

limits become the responsibility of the servicing

technician andlor the owner. Refer

to

Emissions

Compliance

on

p.

150.

If

the carburetor body cover assembly must

be

replaced;

or,

if the original calibration settings are

lost, the following procedure can

be

used

to

make

adjustments based

on

engine performance.

Adjustment of the tamper resistant

needle valve

requires a special

Torx

Screwdriver,

PIN

351204.

Start the engine and

run

it

in

FORWARD at one-

half throttle. Allow the engine to reach normal

operating temperature.

Tiller Models

Face the steering handle. Turn the idle speed

adjustment knob counterclockwise to

lowest

SLOW

speed position.

FUEL SYSTEM

CARBURETOR MIXTURE ADJUSTMENT

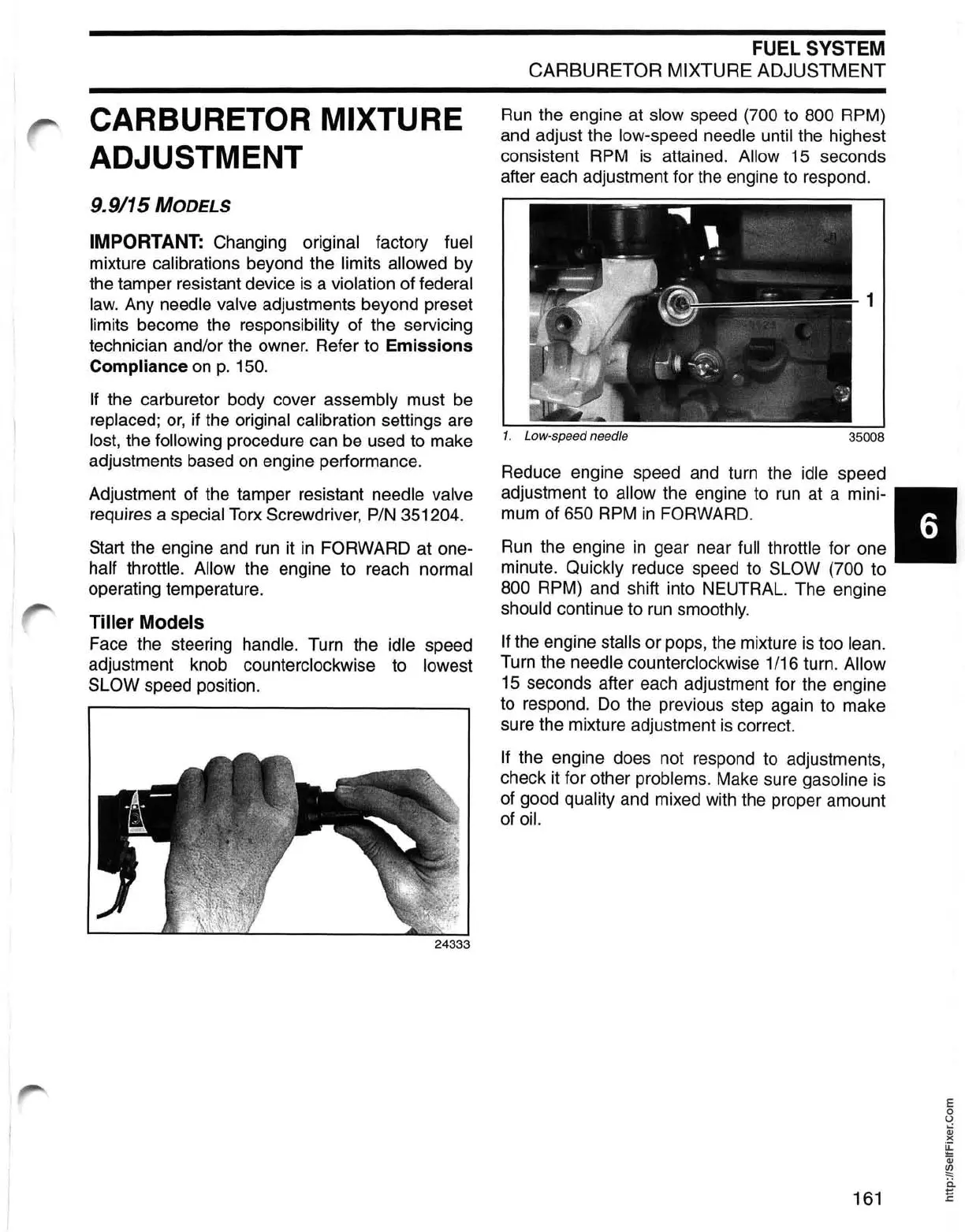

Run

the engine

at

slow speed (700 to 800 RPM)

and adjust the

low-speed needle until the highest

consistent

RPM

is

attained. Allow

15

seconds

after each adjustment for

the

engine

to

respond.

1

Reduce engine speed and turn the idle speed

adjustment to

allow the engine

to

run

at a mini- 6

mum of 650

RPM

in

FORWARD.

Run

the engine

in

gear near full throttle for one

minute.

Quickly reduce speed to SLOW (700 to

800 RPM) and shift into NEUTRAL. The engine

should continue

to

run

smoothly.

If the engine stalls or pops, the mixture

is

too lean.

Turn the needle counterclockwise 1/16 turn. Allow

15

seconds after each adjustment for the engine

to

respond.

Do

the previous step again to make

sure the mixture adjustment

is

correct.

If

the engine does not respond

to

adjustments,

check it for other problems. Make sure gasoline

is

of good quality and mixed with the proper amount

of

oil.

E

o

U

Qj

)(

~

Qj

~

ii

161

E

Loading...

Loading...