GEARCASE

LEAK

TEST

PROCEDURE

LEAK TEST

PROCEDURE

Drain lubricant before testing.

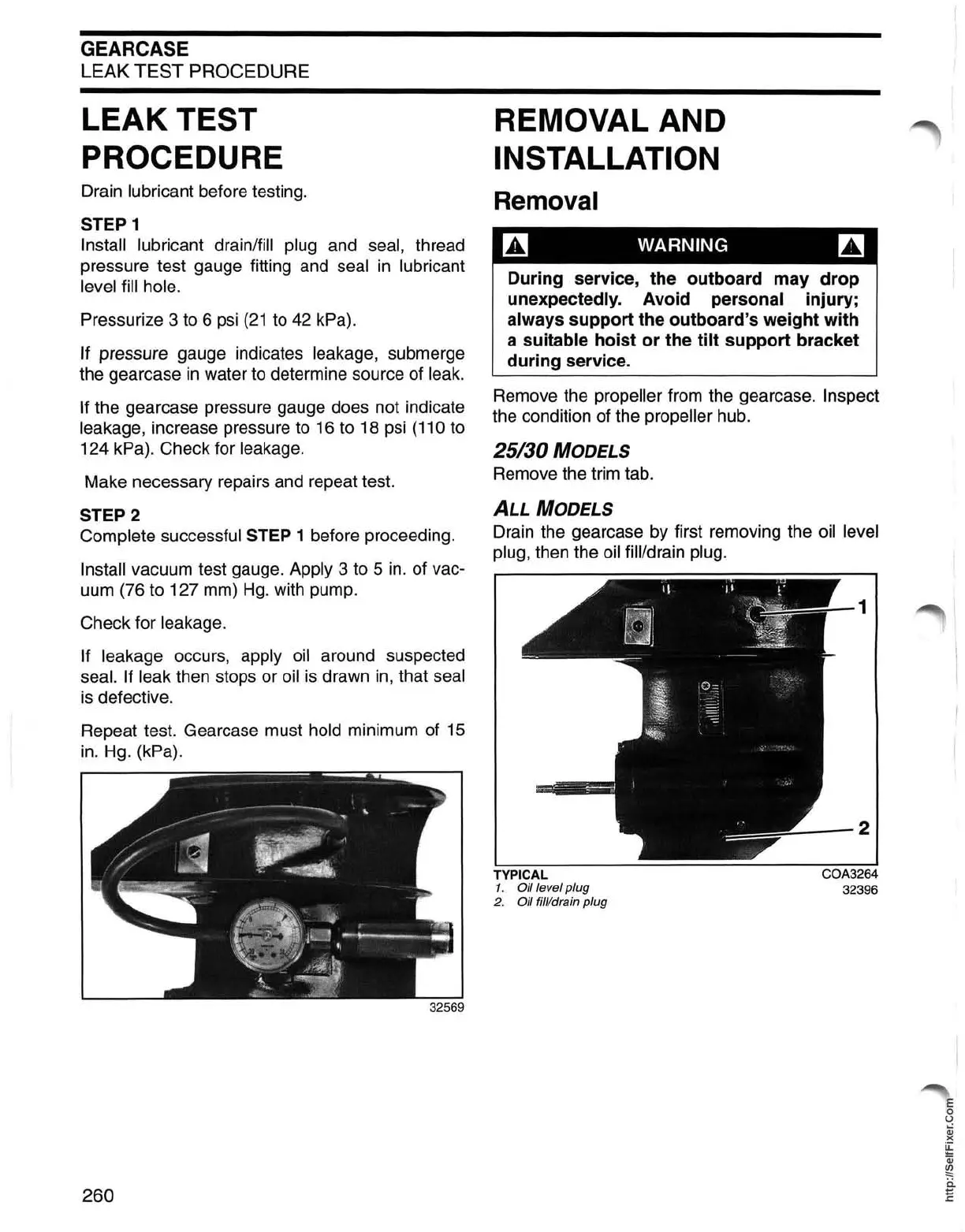

STEP 1

Install lubricant drain/fill plug and seal, thread

pressure test gauge fitting and

seal

in

lubricant

level

fill hole.

Pressurize 3 to 6 psi

(21

to 42 kPa).

If pressure gauge indicates leakage, submerge

the gearcase

in

water to determine source of leak.

If

the gearcase pressure gauge does not indicate

leakage, increase pressure to 16 to 18 psi (110 to

124 kPa). Check for

leakage.

Make necessary repairs and repeat test.

STEP 2

Complete successful STEP 1 before proceeding.

Install vacuum test gauge. Apply 3 to 5

in.

of vac-

uum (76 to 127 mm)

Hg.

with pump.

Check for

leakage.

If leakage

occurs, apply oil around suspected

seal. If leak then stops or oil

is

drawn

in,

that seal

is

defective.

Repeat test. Gearcase must

hold minimum of

15

in.

Hg. (kPa).

260

REMOVAL AND

INSTALLATION

Removal

m WARNING

~

During service, the outboard may

drop

unexpectedly. Avoid personal inJury;

always

support

the outboard's

weight

with

a suitable

hoist

or

the

tilt

support

bracket

during

service.

Remove the propeller from the gearcase. Inspect

the condition of the propeller hub.

25/30 MODELS

Remove the trim tab.

ALL

MODELS

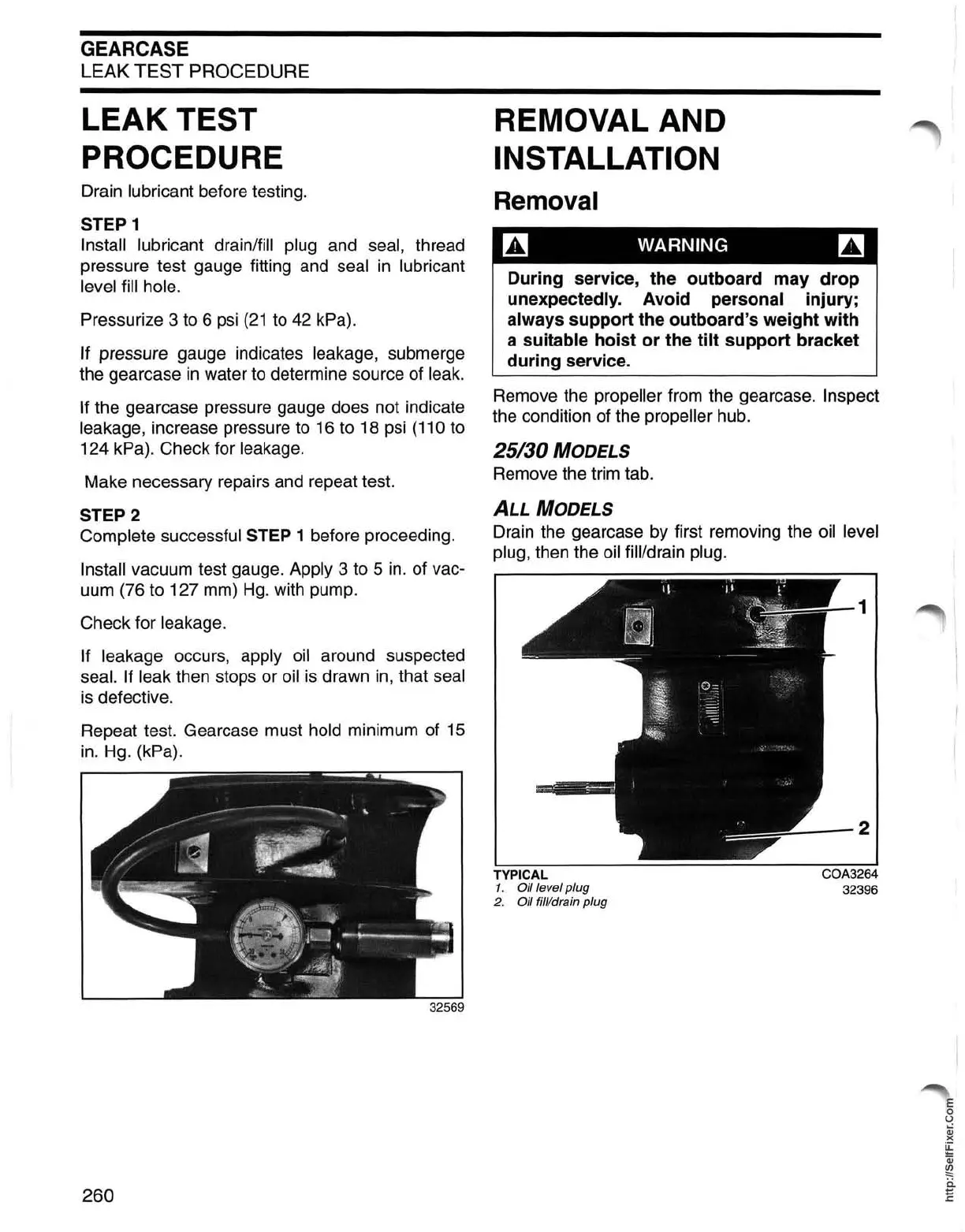

Drain the gearcase by first removing the oil level

plug, then the oil fill/drain plug.

1

~--2

TYPICAL

1.

Oil level plug

32396

2. Oil fill/drain plug

Loading...

Loading...