SP Mode

Tables

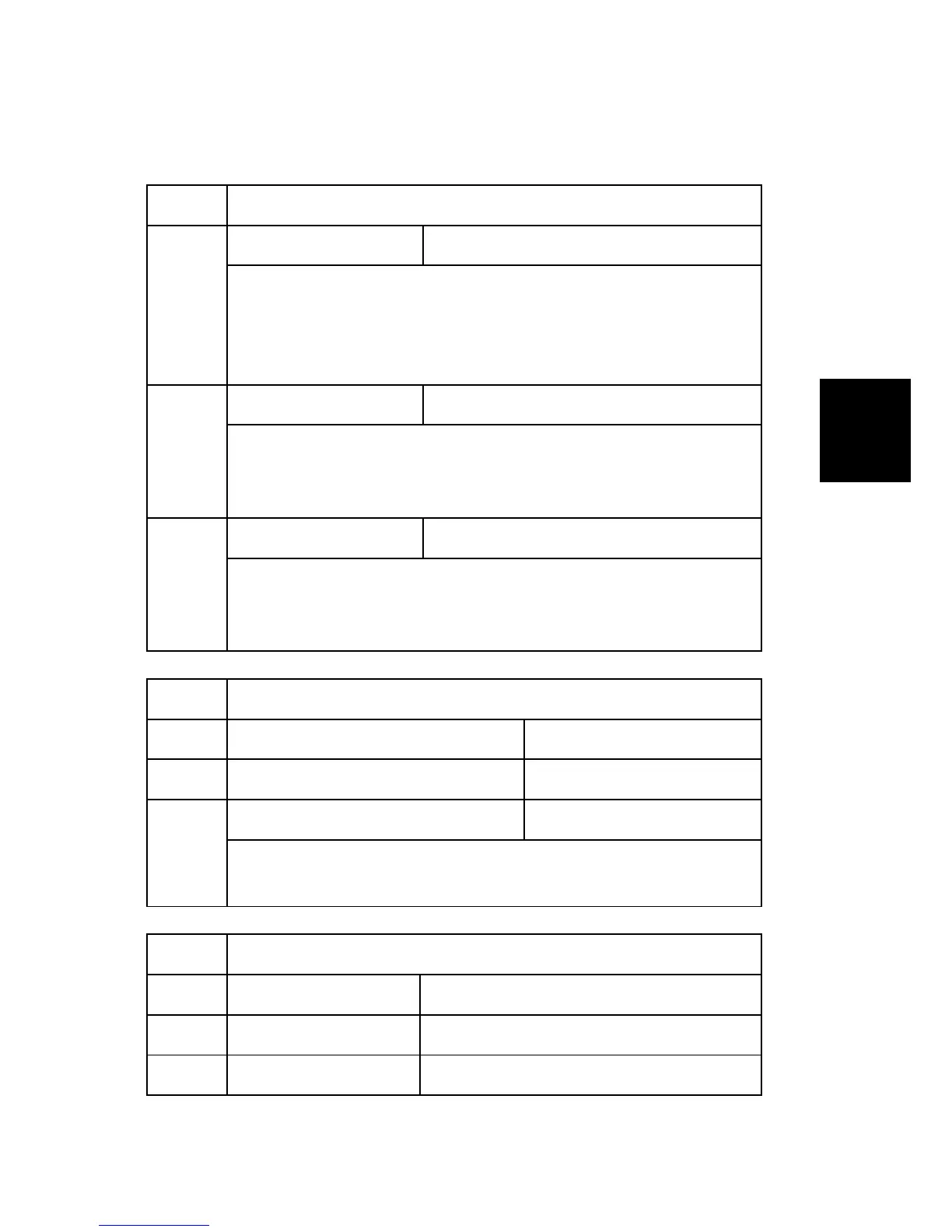

SP2-XXX (Drum)

2001* Charge Roller Bias Adjust

2001 1

Setting (Copying) [–2100 to –1500 / –1700 / 10 V/step]

Adjusts the voltage applied to the charge roller for printing. The voltage

changes automatically as charge-roller voltage control works. The value here

is the base value for the charge-roller voltage control.

The value from -1800 V to -1600 V is preferable.

2001 2

ID sensor pattern [0 to 400 / 200 / 10 V/step]

Adjusts the voltage applied to the charge roller for the ID sensor pattern (as

part of charge-roller voltage correction). Setting the same value as

“SP2-201-002” is preferable.

2001 3

Temporally Input [-2500 to 0 / 0 / 10 V/step]

Inputs the voltage value. Too small value may cause the charge roller tainted.

Too large value may cause attaching carrier particles in developer, on a

printed paper. The value from – 1800 V to 1600 V is preferable.

2005* Charge Bias Correction

2005 1

Charge Roller Bias Correction (Step) [0 to 200 / 50 / 1 V/step]

Sets correction value by one step for bias adjustment to meet SP2001-001

setting value.

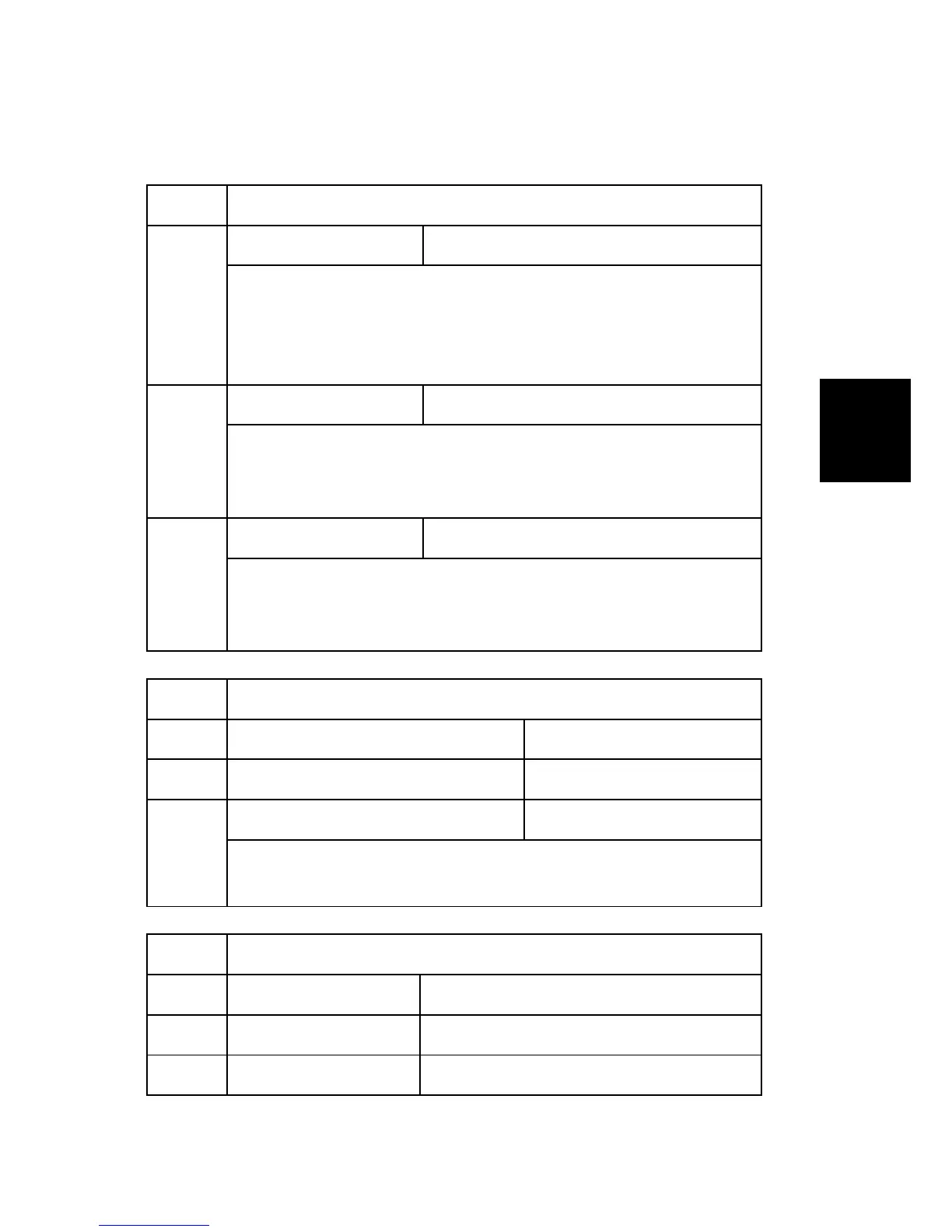

2102* Main Scan Adj.

2102 1 Magnification Adj. [-0.5 to 0.5 / 0 / 0.1%/step]

2102 13 Beam Pitch Dot [0 to 20 / 5 / 1 dot/step]

2005 14 Beam Pitch Subdot [0 to 15 / 3 / 1 sub-dot/step]

Loading...

Loading...