Chapter 4 Engraving

56

4-4 Cutter Installation Method 1 (With Nose Unit)

Installing a Character Cutter (With Nose Unit)

WARNING

Never inadvertently touch the computer or handy panel while performing this

task.

Unintended operation of the machine may result in injury.

WARNING

Securely fasten the cutting tool and in place. After securing in place, make sure

no wrenches or other articles have inadvertently been left behind.

Otherwise such articles may be thrown from the machine with force, posing a risk

of injury

CAUTION

Caution: cutting tool.

The cutting tool is sharp. To avoid injury, exercise caution.

Type of cutter used Character cutter or at cutter

Nose-unit usage Used

Suitable workpiece types Acrylic and other plastic-resin panels

Note: Aluminum, brass, and other easily scratched workpieces are not suitable.

Automatic Z-axis control On

Spindle rotation On

Lock-lever position

or

This performs engraving using the nose unit. When the tip of the nose unit touches the surface of the workpiece, the location

is automatically detected as the Z origin point. This makes it possible to perform engraving at a uniform depth on a work-

piece of uneven surface height. This also eliminates the need to set the Z-axis origin point each time when you’re engraving

a number of dierent workpieces.

1.

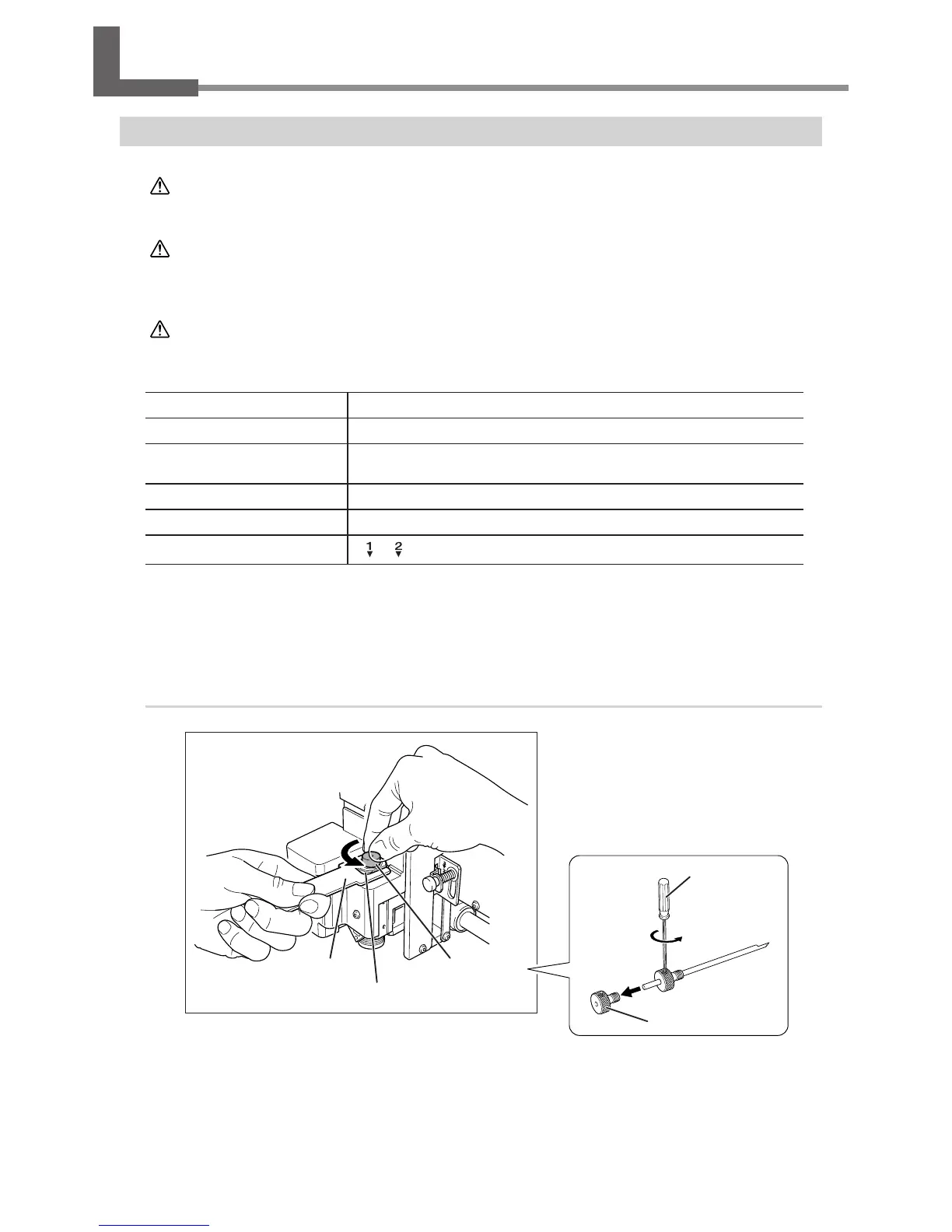

Install the cutter holder, solid collet, and nose unit.

Install the cutter holder

While holding the spindle unit immobile with a

wrench, tighten the cutter holder.

The cutter holder is reverse-threaded (that is, you

turn it counterclockwise to tighten it). Be careful

to turn it in the correct direction.

Wrench

Spindle unit

Cutter holder

Loose

Hexagonal

screwdriver

Cutter holder

Loading...

Loading...