5-3 Surface Leveling of the Workpiece Table

This adjusts the atness of the surface of the workpiece table by cutting the table surface to a uniform depth. This operation

is called “surface leveling” or “surfacing.”

This can be useful in cases where rigorously precise atness is required, such as for plate engraving performed without using

the nose unit. A single surface-leveling operation takes about one hour. If uncut areas remain, perform surfacing a second

time. Also, pausing this operation while in progress is possible, just as with ordinary cutting.

P.49, “Pausing and Resuming Cutting”

Verifying the Cutter Used and the Settings

Cutter used: Included at cutter (ZEC-A2320)

Z-axis origin point (Z0 position): Surface of the workpiece-table center

Lock-lever position:

Spindle speed: 14,000 rpm*

Cutting-in amount: 0.3 mm (invariable)

Cut-out amount: 1 mm (invariable)

Feed rate: 15 mm/sec. (invariable)

Cutting area: Entire X- and Y-axis operating range (invariable)

* The speed of spindle rotation at the time surface-leveling cutting starts is always 14,000 rpm. Watch the status of cutting

and modify this as required.

P. 48, “Adjusting the Spindle Speed,” p. 62, “Cutter Installation Method 2”

Procedure

Carry out steps

1.

and

2.

on page 62 to 63, “Cutter Installation Method 2.”

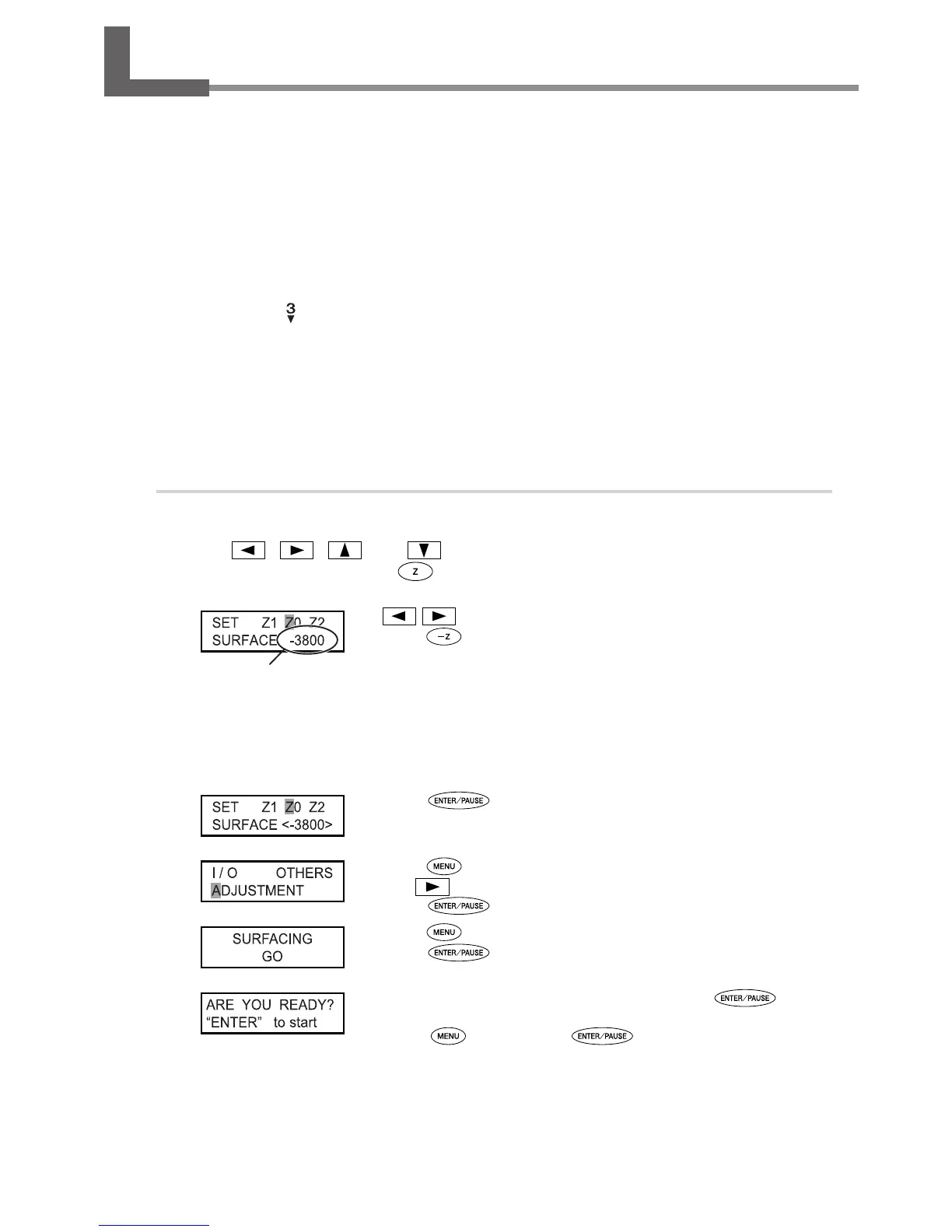

Use , , , and to move the cutter to the area above the center of the

workpiece table, then press

.

P. 44, “Manual Movement”

Use or to select [Z0].

Press

to lower the spindle head to the location where the

Zaxis

coordinate is “-3800.”

Insert a at cutter (ZEC-A2320) into the cutter holder, bring the tip of the cutter into contact

with the surface of the workpiece table, and secure the cutter in place.

For information on how to secure the cutter in place, refer to page 64 and 65.

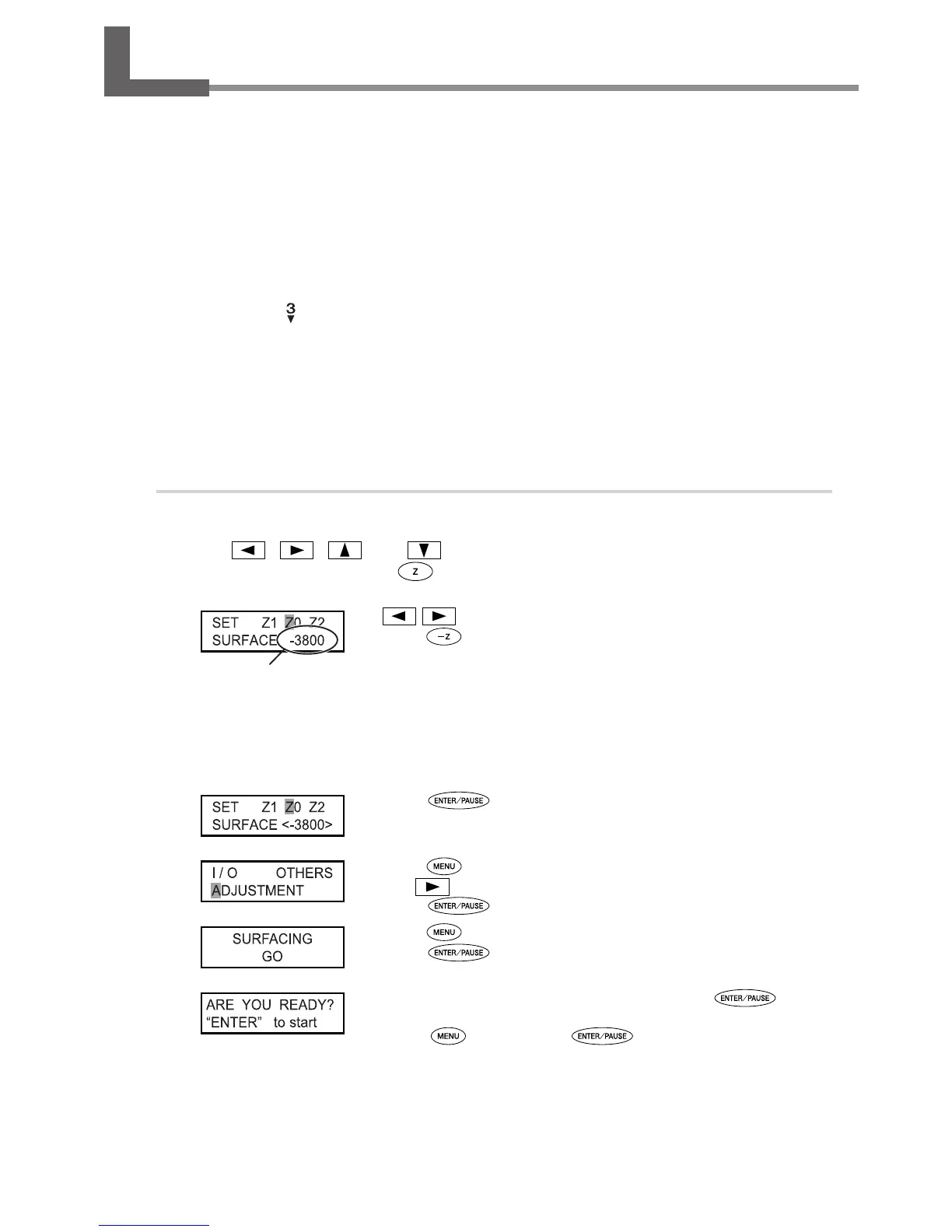

Press to conrm.

The Z-axis coordinate is set.

Press several times to display the view shown at left.

Use

to select [ADJUSTMENT].

Press

.

Press twice.

Press

.

When the screen shown at left appears, press .

The cutting for surface leveling starts.

Pressing

before you press returns you to the screen in step

.

Check visually to ensure that no uncut areas remain.

If uncut areas are present, redo the procedure from step

.

Z-axis coordinate

83

Loading...

Loading...